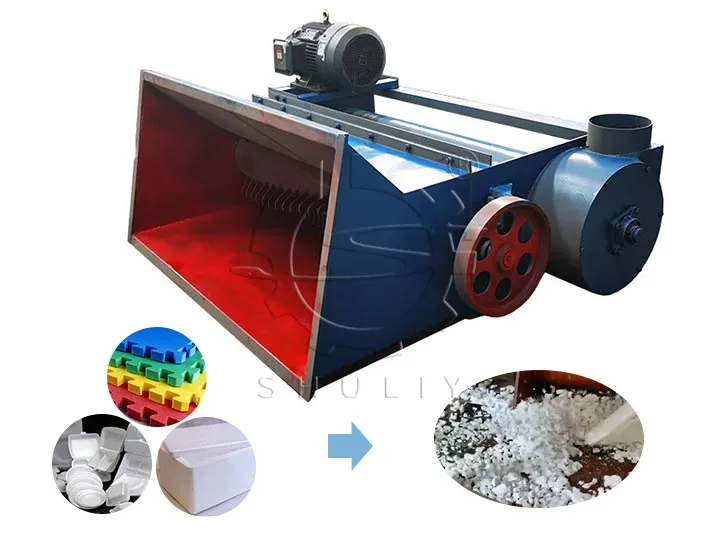

The foam crushing machine is a recycling machine designed primarily to crush EPS, EPE, and EPP foam materials into small pieces for further recycling, such as through extrusion granulation. Additionally, this EPS foam shredder can reduce the volume of plastic foam materials, making them more convenient for transportation. This equipment can be used with an foam granulator to process waste EPS foam into granules.

What Are The Raw Materials of The Foam Crusher?

Our foam crushing machine is a piece of multi-functional equipment that can effectively crush all kinds of foam materials, including but not limited to disposable lunch boxes, thermal insulation boxes, foam inner liners of electronic products, foam filler materials, pearl cotton, foam board, decorative foams, fruit net covers, etc.

Crushed Plastic Foam

The main finished product of the EPS foam shredder is crushed plastic foam. These small pieces of foam can be compacted into blocks by the EPS foam compactor soon, or processed into foam granules by the EPS foam granulator.

Features of Styrofoam Shredder

- High Efficiency Shredding: Breaks large foam pieces into smaller ones for further processing.

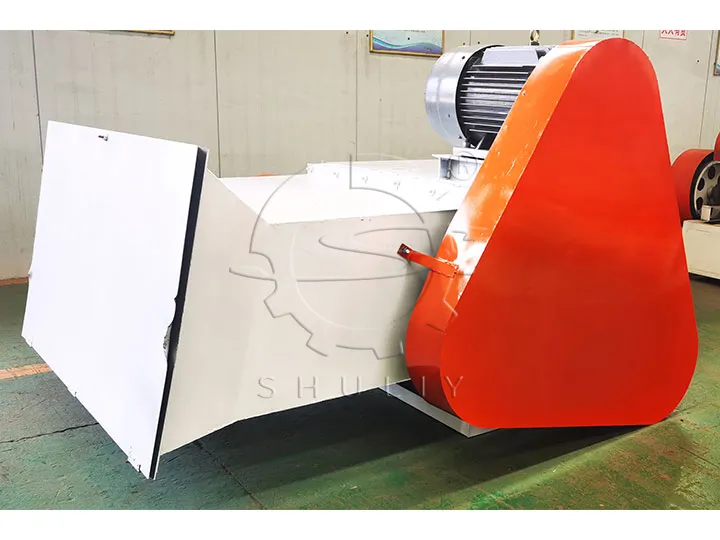

- Horizontal Design: Ground-level feeding for easy material input.

- Versatile Application: Suitable for processing EPS, EPE, XPS, and other foam materials.

- Durable and Reliable: Equipped with high-quality blades for better shredding performance and long service life.

- Enhanced Recycling Efficiency: Prepares foam waste for pelletizing, cold compression, or hot melting.

- Easy to Operate: Simple structure with convenient maintenance.

Structure And Process of Foam Crushing Machine

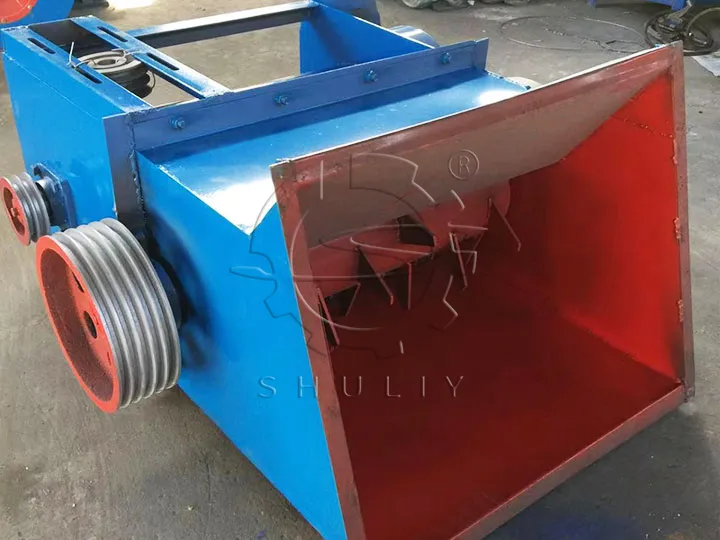

- Inlet: Foam waste can be easily fed into the horizontal foam crusher through its inlet, which is level with the ground. This design allows for the direct and effortless insertion of materials, significantly enhancing convenience while reducing the need for manual labor.

- Cutting room: In the cutting room, sharp blades cut the foam material into small pieces ready for the next step.

- Motor and drive system: The motor and drive system provides the necessary power to ensure an efficient and stable cutting and shredding process.

- Emission system: The crushed foam is conveyed to the next process.

Working Video of Plastic Foam Crusher

Specifications of Horizontal Foam Crusher

- Capacity (KG/H): 250-300

- Overall size (mm): 1250*1290*660

- Feed port size (mm): 800*600

- Power (KW): 5.5

- Capacity (KG/H): 300-350

- Overall size (mm): 1250*1530*660

- Feed port size (mm): 1000*600

- Power (KW): 5.5

- Capacity (KG/H): 450-500

- Overall size (mm): 1600*2200*800

- Feed port size (mm): 1500*800

- Power (KW): 11

Related Foam Recycling Machine

This foam crushing machine is usually used in conjunction with a pelletizer, where the crushed foam is further processed into recycled pellets. In addition, you can choose to have the waste foam hot-melted or cold-pressed. We offer both EPS hot melting machines and styrofoam compactors to meet different recycling needs.

If you want to learn about the various recycling options, you can check them out in this article: Styrofoam Recycling Solutions: Turning Waste Into Resources