Mimina wa mpira wa ufanisi mkubwa ni msingi wa suluhisho kamili la kuchakata matairi Shuliy Mashine ambayo hivi karibuni ilitolewa kwa mteja nchini Kanada. Mteja alilenga kuanzisha biashara ya ndani ya kubadilisha matairi ya taka kuwa vigae vya mpira vya kudumu, kufanikisha urejelezaji wa rasilimali na thamani ya kibiashara. Shuliy Mashine alimpa suluhisho kamili, kuanzia kugawanya matairi na uzalishaji wa unga hadi kutengeneza vigae vya mwisho.

Mahitaji na Changamoto za Mteja

Changamoto kuu kwa mteja wetu wa Kanada ilikuwa ni kusindika matairi ya taka ya ukubwa tofauti, yenye kipenyo cha juu cha 1200mm. Lengo lake kuu lilikuwa ni kuzalisha vigae vya mpira vya ubora wa juu kwa maelezo tofauti ili kusambaza masoko ya ndani kama vile uwanja wa michezo, mazoezi, na njia za kutembea. Kwa hivyo, alihitaji mstari wa uzalishaji kamili na wa kuunganishwa ambao ungeweza kushughulikia kwa urahisi kila hatua kutoka kwa malighafi hadi kwa bidhaa iliyomalizika.

Den anpassade lösningen: Från däck till pulver

Kulingana na malighafi za mteja na malengo ya uzalishaji, tulibuni mstari kamili na wa ufanisi wa uzalishaji wa poda ya mpira.

Hatua ya 1: Uchapishaji wa Mapema wa Gari la Gari

Vi utrustade först produktionslinjen med endäckdemontage-maskin. Denna maskin tar enkelt bort stålkorden från båda sidor av de 1200 mm däcken och skär den återstående delen i avsnitt. Detta förbereder materialet för efterföljande rivningsprocess och förbättrar avsevärt bearbetningseffektiviteten i hela däckåtervinningslinjen.

Dessutom är produktionslinjen utrustad med en dedikeraddäckkantspärr. Denna maskin behandlar banden som har avkapats från däcken, och separerar effektivt den inre ståltråden från gummit. Samtidigt skickas huvuddäcket, med sina band borttagna, direkt till rivningsmaskinen för nästa steg i krossprocessen.

Steg 2: Grovrivning

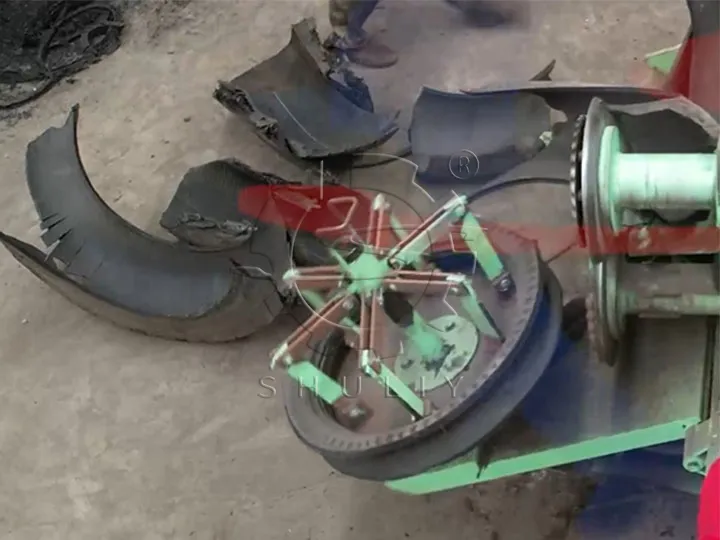

De skurna däckremsorna matas in i en 800däckrivare, som snabbt ripor dem i 3-8 cm gummichips.

Steg 3: Finkorning med SL-400 gummipulverkvarn

Vipande hivi vya mpira vinapelekwa kwenye kiini cha mfumo:mlinzi wa poda ya mpira wa SL-400. Mlinzi huu wa nguvu wa mpira huvunjika vipande kuwa ukubwa wa mesh unaohitajika, wakati mifumo ya kuchuja ya mfumo mzima wa sumaku na nyuzi huondoa waya za chuma na nylon kiotomatiki, kuhakikisha usafi wa poda ya mwisho ya mpira. Utendaji thabiti wa mlinzi wetu wa poda ya mpira ulikuwa sababu kuu ya uamuzi wa mteja.

Från pulver till produkt: Tillverkning av högvärdiga gummiplattor

Det högkvalitativa pulvret som produceras av gummipulverkvarnen är den ideala råvaran för tillverkning av golvplattor. Detta pulver blandas med en bindemedel och andra tillsatser i en 250 blandare och placeras sedan i formar. Slutligen, genom hög temperatur och tryck i en varmpressformmaskin, vulkaniseras materialet till starka och hållbara gummiplattor.

Ili kukidhi mahitaji tofauti ya soko la mteja, tulitoa miundo ya kutengeneza tiles za 500x500mm na 1000x1000mm kwa mifumo tofauti.

Ett framgångsrikt partnerskap och ditt nästa projekt

Detta projekt visar tydligt hur en väl utformad återvinningslinje kan förvandla avfall till en lönsam affärsverksamhet. Den kanadensiska kunden är nu helt utrustad för att producera och sälja högkvalitativa gummiplattor i deras lokala marknad.

Om du också överväger att investera i ett däcksåtervinningsprojekt, oavsett om du behöver en fristående gummipulverkvarn eller en komplett turnkey-lösning, är vårt professionella team redo att hjälpa dig. Kontakta oss idag för din skräddarsydda konsultation.