The plastic shredder machine is widely used in the plastic recycling industry, whether it is a plastic recycling washing line or plastic granulating line, the plastic crusher is essential. It can handle a wide range of materials and crush waste plastics into small pieces for subsequent washing and pelletizing processes.

The capacity of this equipment is 500-1000kg/h, we also have a variety of specifications of crusher machines for plastic to choose from, you can leave a message on the form on our website, and we will give you the most detailed information.

Introduction of Plastic Crusher

Plastic crushers are highly efficient machines that are capable of crushing plastics of various materials into pieces, making them suitable for subsequent processing.

This unit features alloy steel blades for excellent wear resistance and strong durability, so it can run stably for long periods of time, reducing maintenance costs. During the shredding process, the operator can also add water, which not only enhances the cleaning effect of the plastic chips but also reduces the friction heat through the cooling effect of water, prolonging the service life of the blades. This feature is very beneficial in long-term operation and helps to reduce equipment maintenance costs.

It is worth mentioning that our crusher machine for plastic is highly praised in the international market. Foreign customers have highly recognized its high efficiency, reliability, and low maintenance cost.

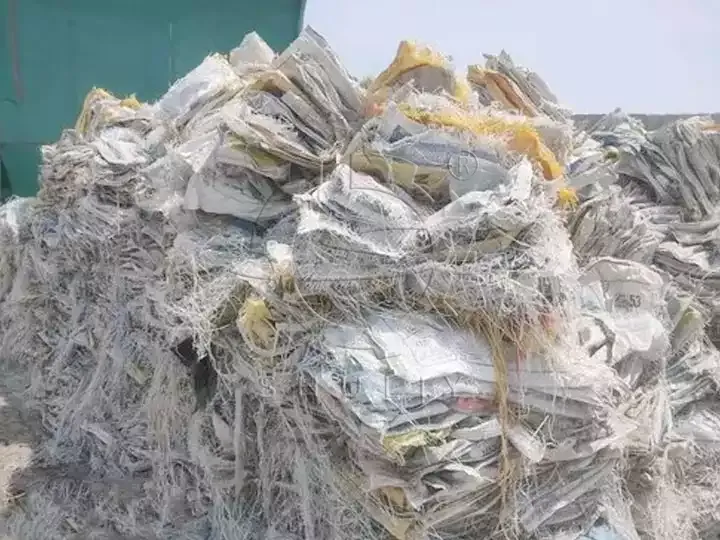

Raw Materials Of Plastic Shredder Machine

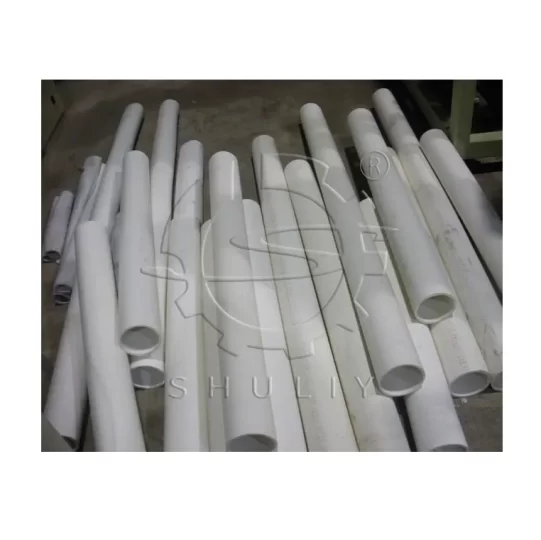

Plastic recycling crushers are suitable for processing a wide range of plastic materials, including soft materials such as plastic bags, woven bags, agricultural films, industrial films, heat-shrinkable films, rubbish bags, etc., as well as hard materials such as plastic buckets, plastic bottles, tubes, plastic baskets, and food containers.

Crushing Effect Display

How Does A Plastic Shredder Work?

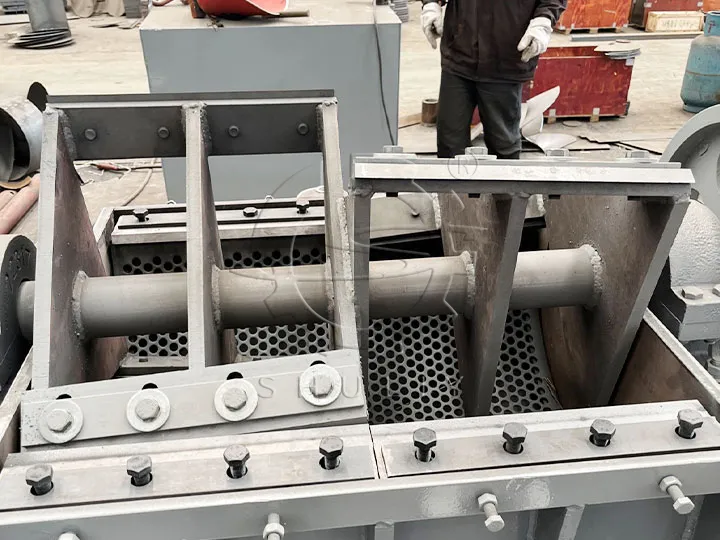

The main structure of the crusher machine for plastic has an inlet, crushing chamber, blade, knife frame, screen, and outlet.

During operation, the motor drives the internal blades to rotate at high speed. The moving and fixed blades create an angle during the high-speed rotation, thus cutting the plastic. The crushed plastic pieces will be filtered through the screen and then output to the discharge port for the next processing procedure.

Application Video of Crusher Plastic Machine

Parameters of Plastic Shredder Machine

We offer a wide range of hot-selling models of plastic shredder recycling machines, including the following popular models with parameters. In addition, we offer a wide range of other models to meet different output and processing needs.

You can choose the plastic shredder machine model that suits your business and ensures optimal productivity. For more models and detailed information, please feel free to contact us.

- Capacity: 600-800kg/h

- Motor power: 30kw

- The Number of knives: 10pcs

- Material of knives: 60Si2Mn

- Capacity: 800-1000kg/h

- Motor power: 45kw

- The Number of knives: 10pcs

- Material of knives: 60Si2Mn

- Capacity: 1000-1200kg/h

- Motor power: 55kw

- The Number of knives: 10pcs

- Material of knives: 60Si2Mn

Features of Crusher Machine For Plastic

- Compressive strength: >300MPA

- Screen: The screen size of the plastic crusher is 24mm for hard material and 90mm for film material.

- Low noise: low noise is generated during operation, creating a good working environment.

- Low maintenance cost: the use of wear-resistant alloy steel blades, long service life, reducing equipment maintenance costs.

- No slag: Virtually no slag is produced, minimizing waste.

How To Maintain Plastic Waste Crushing Machine?

Regular maintenance is essential to ensure proper functioning and long service life.

Firstly, the operator should regularly clean the residues and foreign objects inside the plastic shredder machine to prevent clogging and damage to the knives. Secondly, the wear and tear of the knives should be checked regularly and the badly worn blades should be replaced in time to maintain the crushing effect.

In addition, the addition of lubricant is also a key step to ensure that the components maintain good lubrication during operation and reduce friction loss. Finally, operators should regularly check the electrical components and safety devices to ensure the safety performance of the equipment.

Through these simple but effective maintenance measures, you can improve the stability and efficiency of the plastic crusher and extend its service life.

Plastic Shredder Machine Price

The price of a plastic crusher can vary depending on factors such as capacity, features, and brand. Our plastic crusher is affordable and quality is guaranteed. If you are interested, please contact us as soon as possible, and we will give you the best plastic shredder machine price.

In addition to plastic recycling crusher machines, we also offer waste plastic extrusion machines that can process plastic into plastic pellets, as well as professional PET bottle recycling machines that recycle PET bottles. Wherever you want to recycle plastics, we can give you a complete solution.

Global Cases of Crusher Plastic Machine

Two Plastic Crushers Exported To Ghana

Shuliy Machinery has successfully exported two plastic shredder machines to Ghana. The model chosen by the customer is SL-600, with a capacity of 600-800kg/h. If you also need this plastic recycling machine, please contact us via the form at the bottom of the website.

Plastic Recycling Crusher Machine Sent To Somalia

We ship to Somalia with a model SL-800 plastic recycling crusher machine, which is used by the customer to crush hard plastics. After the completion of the machine, the customer personally came to acceptance, and is very satisfied with the crushing effect!