Plastic granulator machine plays a vital role in the PP PE plastic granulating line, their main function is to process waste, broken, or cleaned plastic materials into plastic pellets of uniform specifications for use in the manufacture of various plastic products.

As a professional plastic granulator manufacturer, all our plastic recycling machines are CE-certified and have been approved by many customers. Especially, the plastic pelletizers of Shuliy Machinery have been sold to Cote d’Ivoire, Oman, Saudi Arabia, Germany, Ghana, Kenya, Mozambique, and Nigeria. If you need to process waste materials into plastic granules, you can choose the plastic granulator machine from Shuliy Machinery.

What Is A Plastic Granulator Machine?

The extruder for plastic recycling is a device used to process waste or recycled plastic materials into plastic pellets. The main function of the machine is to heat and melt the plastic and pull the strips for granulation. This plastic pelletizer is suitable for a wide range of plastic raw materials, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and more.

The plastic pelletizing machine has a reasonable structure, easy to operate, and can be used in conjunction with the plastic crusher, washing machine, etc. to form a complete production line. We can provide you with plastic granulators of different capacities, welcome to contact us!

Raw Materials And Final Products

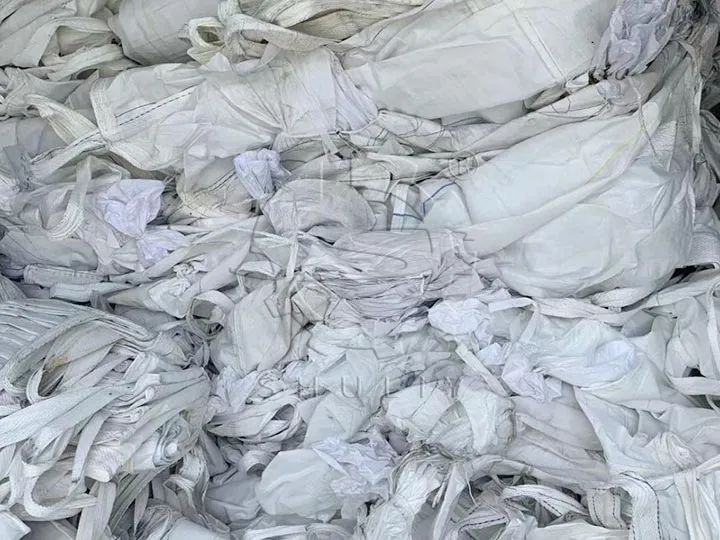

Our plastic granulator machines are suitable for a wide range of raw materials, including soft materials such as plastic bags, woven bags, and mulch films, as well as hard plastics such as pipes, plastic drums, and tubs. The machine can process these waste plastics into recycled plastic pellets. You can come to us for consultation according to your raw materials, and we can recommend the most suitable extruder for plastic recycling for you.

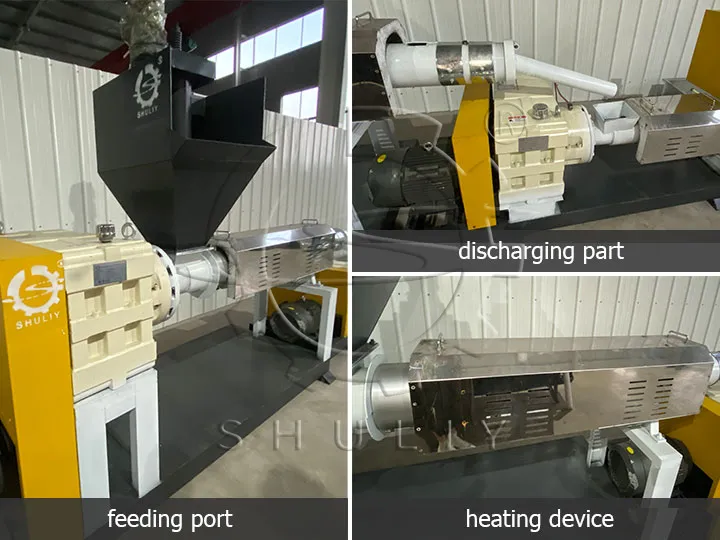

Structure of Extruder For Plastic Recycling

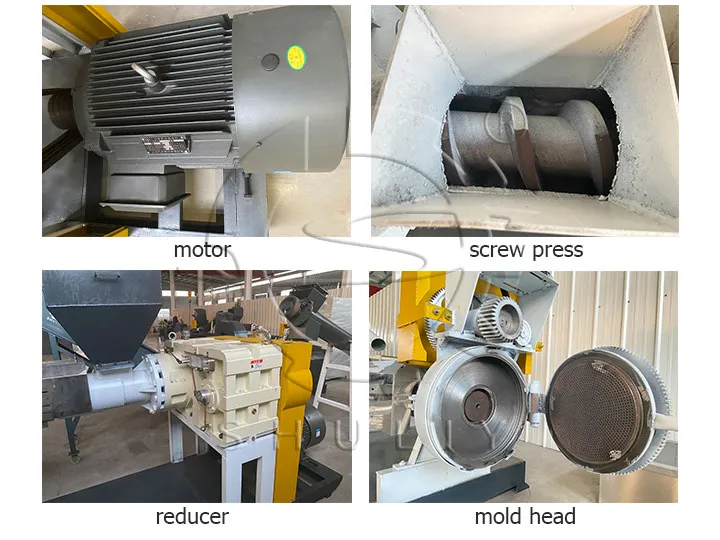

The main components of this plastic pelletizing machine are a feed inlet, automatic feeding device, reducer, heating device, screw, motor, and mold head.

- Feeding Port: This is where the raw material enters the plastic granulator machine.

- Auto Feeder: The automatic feeding device is used to automatically feed lighter materials into the plastic pelletizer.

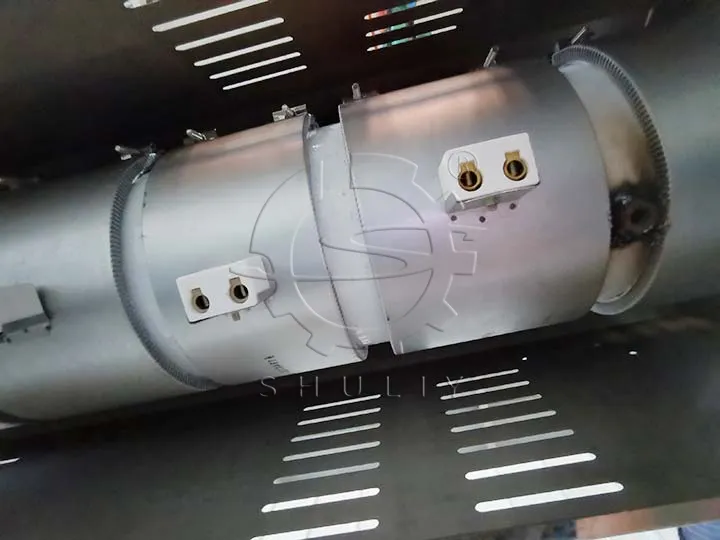

- Heating Device: This is the key part of the plastic recycling machine and is used to heat the plastic to melt it, we have a wide range of heating options to choose from.

- Screw: The material is conveyed to the die head by rotary extrusion.

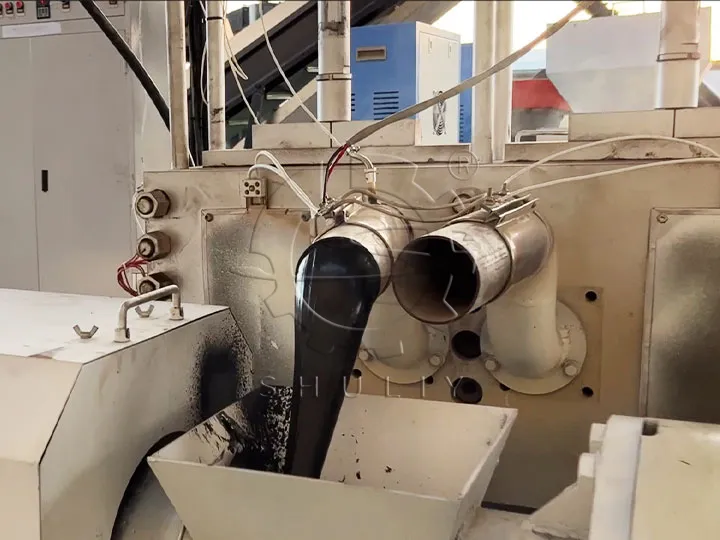

- Die Head: The die head is used to extrude the plastic in long strips for subsequent cooling and cutting into uniform plastic pellets. Shuliy Machinery offers a wide range of die heads that can meet your different production needs.

Three Heating Methods For Plastic Granulator Machine

The heating methods of the plastic pelletizing machine are electromagnetic heating, ceramic heating, quartz tube heating, ordinary electric heating, and so on. Among them, electromagnetic heating is the most effective heating method.

Electromagnetic heating: Winding the electromagnetic coil on the outer wall of the cylinder, short preheating time, high efficiency and energy saving, and long service life. This is the most effective way of heating.

Ceramic heating: Ceramic heating is also one of the more popular heating methods with customers. Ceramic heating elements ensure that the heat is evenly distributed during the process, thus ensuring uniform heating of the raw material.

Ordinary electric heating: It is also called an iron heating device, which adopts high-quality nickel chrome alloy electric heating wire as a heating element with moderate power and internal and external heat dissipation.

Three Die Heads of Plastic Pelletizer

There are three types of die heads for plastic granulator machines: electric gear die heads, hydraulic die heads, and screenless slag discharge die heads. The function of the die head is to extrude the melted plastic into strips for subsequent cooling and cutting into pellets. Customers can choose the right die head according to their needs.

How Does A Plastic Pelletizer Work?

Working Principle Of Plastic Pellet Making Machine

The working principle of the plastic granulator machine is very simple. Firstly, the waste plastic enters into the plastic pelletizing machine and melts through the heating device, then the melted plastic enters into the pelletizing machine auxiliary machine, which is conveyed forward through the screw and extrudes the plastic long strips from the die head. Finally, the cooled plastic strip enters the plastic granule cutter to be cut into small granules.

FAQs Of Extruder For Plastic Recycling

What Plastic Raw Materials Is This Plastic Granulator Machine Suitable For?

Our plastic pelletizing machines are suitable for a wide range of plastic types such as PP, PE, HDPE, LDPE, PVC, PS, and ABS.

Is After-sales Service And Technical Support Available?

Yes, we provide comprehensive after-sales service and technical support to ensure that our customers receive help and maintenance during use.

Which Type Of Maintenance Does This Machine Require?

Regular cleaning, lubrication, and inspections are essential to ensure proper machine operation. We provide detailed maintenance guidelines.

How Is It Purchased And Delivered?

You can purchase our products by contacting our sales team via the contact form at the bottom of our website. We offer a worldwide delivery service.

Global Case of Plastic Granulator Machine

Plastic Pellet Making Machine Exported To Ghana

The Ghanaian customer chose the SL-260 plastic granulator from Schulich, which has a new look and a processing capacity that fully meets the customer’s needs. The machine has already arrived in Ghana. If you are interested, please check it out: SL-260 Plastic Pellet Making Machine Exported To Ghana.

Feedback On Plastic Pelletizing Recycling Machine In Côte D’Ivoire

Customers in Côte d’Ivoire have chosen our plastic pelletizing recycling machine to process rigid plastics. The machine is now in operation and producing high-quality plastic pellets. The Ivorian customer is very satisfied and gave us feedback. For more information, please check out: Rigid Plastic Recycling Plant In Operation In Côte D’Ivoire.

Plastic Granulator Machine Price

If you want to know more details or quotation about the Shuliy plastic pellet making machine, please feel free to contact us. Our sales managers can recommend the most suitable plastic pelletizing machine for you and may also customize a complete solution for you.