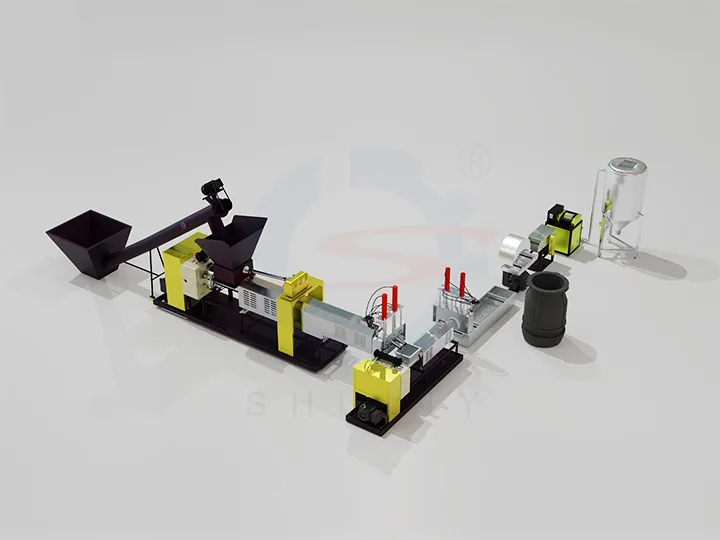

Shuliy’s plastic pelletizing line is an efficient solution for processing rigid plastics into recycled plastic granules. The main equipment of this plastic waste recycling plant includes a plastic crusher, plastic washing machine, horizontal dryer, pelletizer machine, and plastic granule cutter.

Through the precise combination of these individual machines, we realize an efficient plastic pellet production process designed to meet your production needs. The capacity of this plastic pelletizing line is 100kg/h-500kg/h. Of course, we are also able to offer larger capacities according to your needs.

Raw Materials of Plastic Pelletizing Line

Our hard plastic pelletizing lines process two main types of raw materials: post-industrial plastic recycling and post-consumer recycled plastic.

Post-Industrial Plastic Recycling

Plastic waste from industrial processes is called “post-industrial plastics” and consists of large quantities of trimmings and scrap. These wastes are usually clean and uncontaminated and can be processed directly into pellets by producers for reuse in the manufacture of new plastic products.

These materials typically include plastic sheets, pipes, containers, automotive parts from the injection molding process, and appliance housing trim or scrap. Our pelletizing equipment can process them into granules and put them into production again, effectively reducing production costs.

Post-Consumer Recycled Plastic

Post-consumer recycled plastic refers to plastic products that have been used by consumers and recycled. This type of plastic includes beverage bottles, food containers, detergent bottles, and other plastic products used in daily life. This material must be fully cleaned in a washing line and the moisture content controlled below a certain level so that the output pellets can be used to produce new products of acceptable quality.

Finished Product-Plastic Granules

Our hard plastic pelletizing line can produce high-quality, pure, and excellent-performance plastic granules. It is suitable for injection molding, thermoforming, and other processes, and is widely used in the manufacture of plastic bottles, containers, toys, household goods, and auto parts.

Plastic Pelletizing Process

1, Plastic Shredding: In the first step of the plastic waste recycling plant, the hard plastic raw materials (e.g. PE, PP, PVC, PS, PC, ABS, etc.) are first finely crushed through a shredder machine. This step cuts down the large plastic material into small particles, ready for the next step of processing.

2, Washing and Impurity Removal: After crushing, the plastic flakes enter a plastic washing machine where they are washed and soaked to remove residual impurities and contaminants. This ensures that the final plastic pellets are of premium quality.

3, Drying: After being removed from the plastic washing machine, the plastic flakes are passed through a horizontal dryer to eliminate excess moisture, ensuring that the plastics are suitable for subsequent processing.

4, Plastic granulation: This is the central step of the plastic pelletizing line. Under the action of a pelletizer machine, the plastic is subjected to high temperatures and pressures, gradually melts, and is extruded into long plastic strips through a die head. The size and shape of these granules can be adjusted to the customer’s needs.

5, Cooling: The newly manufactured plastic granules are rapidly cooled in a cooling tank to maintain their stable shape and quality before being discharged.

6, Granule Cutting: Finally, the plastic pellets undergo cutting with a plastic granule cutter to achieve the desired pellet size.

3D Video Of Plastic Recycling Granulating Line

Plastic Pelletizing Line Machinery

Plastic Crusher

The plastic crusher is used to crush PP, PE, PVC, PS, ABS, and other raw materials into plastic flakes, reduce the volume of materials, convenient for washing and granulation.

This shredder has an adjustable screen aperture of 20-26 mm. The blades are made of 60Si2Mn material with excellent wear resistance.

Plastic Washing Machine

The plastic washing machine is made of stainless steel and is used to clean broken plastic flakes. As we can see, there are many toothed plates in the tank to rinse the plastic effectively and force the material to move like the other end.

Our standard rinsing tanks are 15-20m in size and are suitable for pelletizing capacities of 100-500kg/h. We can also customize longer rinsing tanks for larger capacities.

Horizontal Dryer

The horizontal dryer is specially used for dewatering and drying hard plastic flakes, which has a high dewatering rate and a high degree of automation.

The centrifugal dryer is capable of drying plastic sheets to 95%-98% moisture and is equipped with drying ducts to further control moisture to 0.5%-1%.

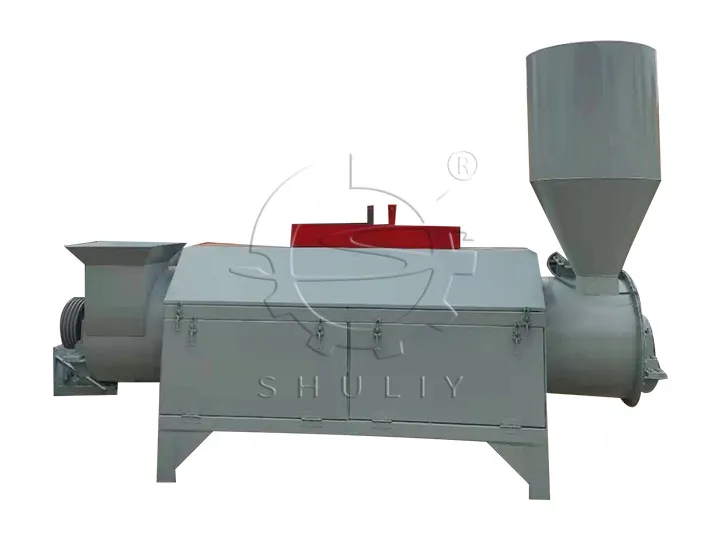

Plastic Granulator Machine

The plastic granulator machine is the core equipment of the plastic pelletizing line, which is used to heat and melt the plastic after crushing, washing, and drying, and pull the strips for pelletizing.

This pelletizer is reasonably designed and mainly consists of a feeding port, screw press, reducer, heating device, pressing chamber, discharge port, mold head, body, base, motor, and other parts. The production efficiency is high, and different models can be selected according to different production capacities.

Cooling Tank

The cooling tank is used to rapidly cool and solidify soft strips of plastic extruded from plastic granulator machines. The unit is made of stainless steel and is available in custom lengths.

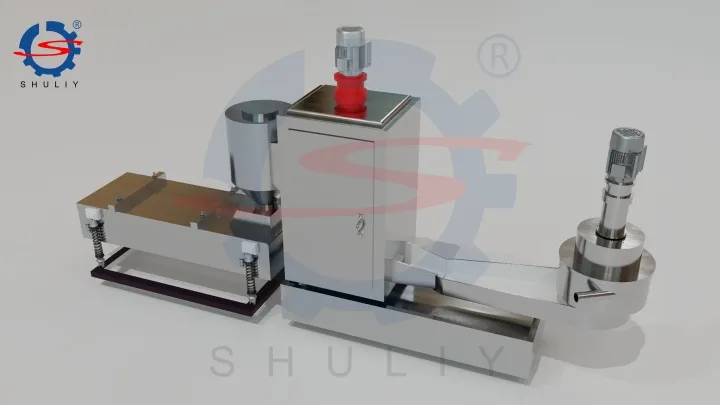

Plastic Granule Cutter

The plastic granule cutter is used to cut long strips of plastic into uniform-sized granules with adjustable cutting pitch.

The pellet cutting machine uses a carbide hob to cut the granules, and the size of the pellets is about 3mm. To improve the uniformity and quality of the granules, it can be equipped with vibrating screens to separate the unqualified pellets.

Features of plastic waste recycling plant

Our plastic pelletizing lines are remarkably flexible and adaptable.

First of all, the equipment configuration is flexible, you can provide a complete production line according to the demand, or only configure the cleaning part or granulation part, to meet different production scales and process requirements.

Secondly, in addition to the traditional strand pelletizing method, we also provide water ring pelletizing, which adapts to the processing needs of different plastic materials and provides more choices.

Finally, the direction of the granulation line can be adjusted according to the layout and area of the customer’s plant to ensure a reasonable layout of the equipment, an efficient production process, and full use of plant space.

Pelletizing Line Specifications

| Parameter category | Details |

| Raw materials | Plastic chairs, toy parts, baskets, trash cans, pipes, bottles, bottle caps, food containers, detergent bottles, plastic sheets, pipes, containers, automotive parts, and appliance housing trim. |

| Plastic material | PP, HDPE, PVC, PS, ABS, PA, PC, etc |

| Finished product | Plastic granules of about 3mm |

| Production capacity | 100-500kg/h, customizable |

| Pelletizing method | Strand pelletizing, water ring cutting pelletizing |

| Equipment configuration | Complete production line, washing section only, granulating section only |

| Optional equipment | Pellet cutting equipment, strip blowers, vibrating screens, force feeders |

| Customized production lines | Adjust the direction of the production line according to the layout and area of the plant. |

Plastic Recycling Plant For Sale

Feedback On Plastic Recycling Granulating Line In Côte D’Ivoire

Feedback from customers in Côte d’Ivoire is that the plastic recycling granulating line is working well. The customer uses the machine to process waste HDPE bottles into high-quality plastic granules.

Rigid Plastic Recycling Plant Sent To Oman

Omani customer wants to recycle PP battery shells, so we customized the plastic recycling washing line for them. The machine has already been shipped to the Omani customer’s plastic recycling factory.

Plastic Waste Recycling Machinery Manufacturer

As a professional plastic waste recycling machinery manufacturer, we have been committed to providing efficient and reliable solutions to help our customers achieve the recycling and reuse of waste plastics.

If you have any questions about our products or need more detailed information, please do not hesitate to contact us at any time. You can leave a message on our website and our team will be happy to provide you with professional support and personalized solutions to meet your specific needs.