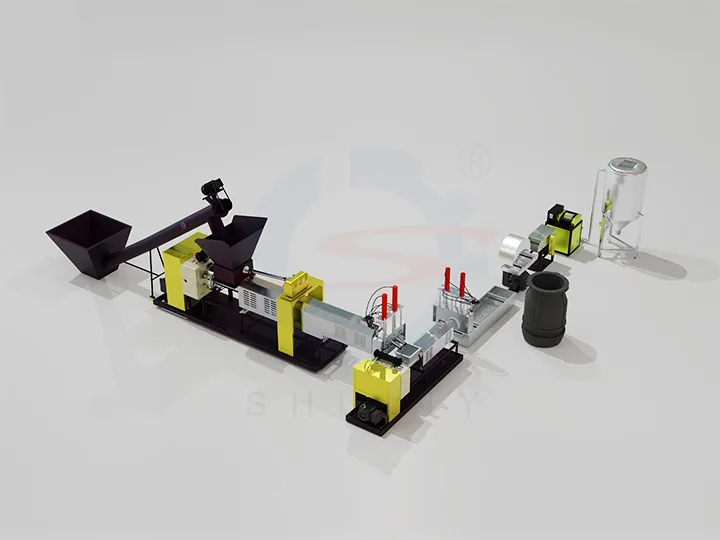

Shuliy 的塑料造粒生产线是将硬质塑料加工成再生塑料颗粒的有效解决方案。该塑料垃圾回收厂的主要设备包括塑料破碎机、塑料清洗机、卧式烘干机、造粒机、塑料颗粒切割机。

通过这些单独机器的精确组合,我们实现了高效的塑料颗粒生产工艺,旨在满足您的生产需求。该塑料造粒线的产能为100kg/h-500kg/h。当然,我们也可以根据您的需求提供更大的容量。

塑料造粒线原料

我们的硬塑料造粒线主要加工两种类型的原材料:工业后塑料回收和消费后回收塑料。

后工业塑料回收

工业过程中产生的塑料废物被称为“后工业塑料”,由大量边角料和废料组成。这些废物通常是干净且未受污染的,可以由生产商直接加工成颗粒,以便在新塑料产品的制造中重复使用。

这些材料通常包括塑料板、管道、容器、注塑过程中的汽车零件以及电器外壳装饰或废料。我们的造粒设备可以将它们加工成颗粒并再次投入生产,有效降低生产成本。

消费后再生塑料

消费后再生塑料是指已被消费者使用并回收的塑料制品。这类塑料包括饮料瓶、食品容器、洗涤剂瓶以及其他日常生活中使用的塑料制品。这种材料必须在清洗线上进行充分清洗,并将水分含量控制在一定水平以下,以便输出的颗粒可以用于生产质量合格的新产品。

成品-塑料颗粒

我们的硬塑料造粒线可以生产出高品质、纯净、性能优良的塑料颗粒。适用于注塑、热成型等工艺,广泛应用于塑料瓶、容器、玩具、家居用品、汽车零部件等制造。

塑料造粒工艺

1、塑料撕碎:在塑料废料回收厂的第一步,硬质塑料原料(如PE、PP、PVC、PS、PC、ABS等)首先通过撕碎机进行精细粉碎。此步骤将大塑料材料切割成小颗粒,为下一步加工做好准备。

2、清洗除杂:破碎后的塑料片进入塑料清洗机进行清洗、浸泡,去除残留的杂质和污染物。这确保了最终的塑料颗粒具有优质的品质。

3、干燥:塑料片从塑料清洗机中取出后,经过卧式干燥机,消除多余的水分,确保塑料适合后续加工。

4、塑料造粒:这是塑料造粒生产线的核心步骤。在造粒机的作用下,塑料在高温和高压下逐渐熔化,并通过模具头挤出成长条塑料。颗粒的大小和形状可以根据客户的需求进行调整。

5、冷却:新生产的塑料颗粒在冷却槽中快速冷却,保持形状和质量稳定后排出。

6、颗粒切割:最后,塑料颗粒经过塑料颗粒切割机的切割,达到所需的颗粒尺寸。

塑料回收造粒线3D视频

塑料造粒线机械

塑料破碎机

塑料破碎机用于将PP、PE、PVC、PS、ABS等原料破碎成塑料片,减少材料体积,便于清洗和造粒。

该碎纸机的筛网孔径可调节为 20-26 毫米。刀片采用60Si2Mn材料制成,具有优良的耐磨性。

塑料清洗机

塑料清洗机采用不锈钢制造,用于清洗破碎的塑料片。我们可以看到,水槽内有许多齿板,可以有效冲洗塑料并使材料在另一端移动。

我们的标准冲洗槽尺寸为 15-20m,适合 100-500kg/h 的造粒能力。我们还可以定制更长的冲洗槽以获得更大的容量。

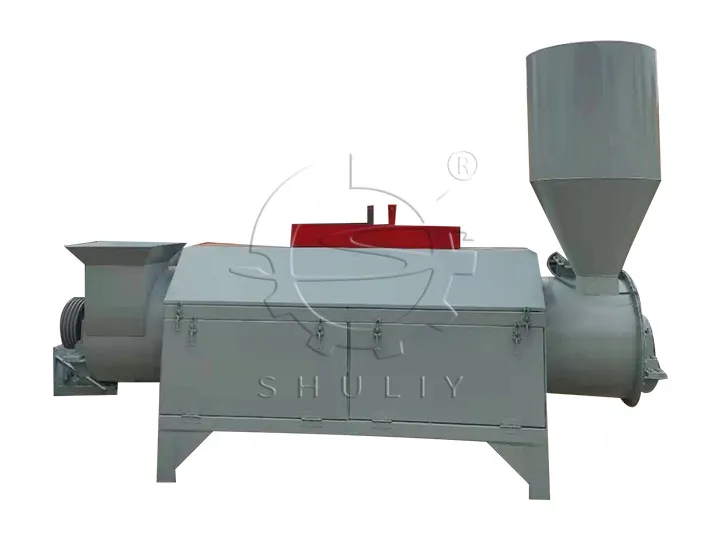

塑料造粒机

塑料造粒机 是塑料造粒生产线的核心设备,用于在破碎、清洗和干燥后加热和熔化塑料,并拉伸成条状进行造粒。

该造粒机设计合理,主要由加料口、螺旋压榨机、减速机、加热装置、压制室、出料口、模头、机体、底座、电机等部分组成。生产效率高,可根据不同的生产能力选择不同的机型。

冷却槽

冷却槽用于快速冷却和固化从塑料造粒机挤出的软塑料条。该单元由不锈钢制成,并可根据需要定制长度。

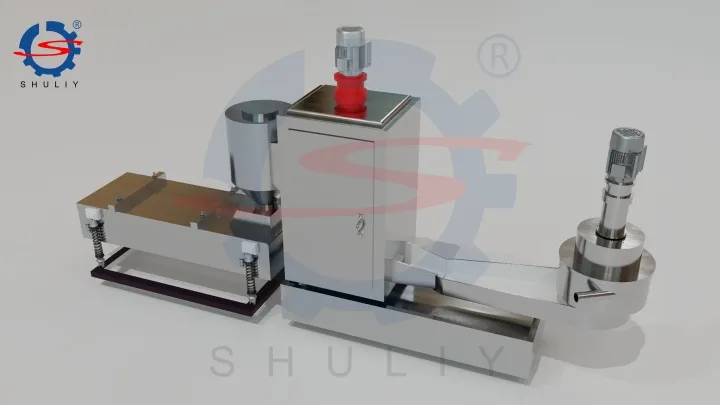

塑料颗粒切割机

塑料颗粒切割机用于将长条塑料切割成均匀大小的颗粒,切割间距可调。

颗粒切割机采用硬质合金滚刀切割颗粒,颗粒尺寸为3mm左右。为提高颗粒的均匀度和质量,可配备振动筛,将不合格的颗粒分离出来。

废塑料回收厂的特点

我们的塑料造粒线非常灵活且适应性强。

首先,设备配置灵活,可以根据需求提供完整的生产线,也可以只配置清理部分或造粒部分,以满足不同的生产规模和工艺要求。

其次,除了传统的拉条造粒方式外,我们还提供水环造粒,适应不同塑料材料的加工需求,提供更多选择。

最后,可以根据客户厂房的布局和面积调整造粒线的方向,确保设备布局合理、生产流程高效、厂房空间得到充分利用。

造粒生产线规格

| 参数类别 | 细节 |

| 原料 | 塑料椅子、玩具零件、篮子、垃圾桶、管道、瓶子、瓶盖、食品容器、洗涤剂瓶、塑料板、管道、容器、汽车零件和电器外壳装饰。 |

| 塑料材质 | PP、HDPE、PVC、PS、ABS、PA、PC 等 |

| 完成的产品 | 3mm左右的塑料颗粒 |

| 生产能力 | 100-500kg/h,可定制 |

| 造粒方式 | 拉条切粒、水环切粒 |

| 设备配置 | 完整的生产线,仅洗涤工段,仅造粒工段 |

| 可选设备 | 颗粒切割设备、带材鼓风机、振动筛、强制给料机 |

| 定制生产线 | 根据厂房布局及面积调整生产线方向。 |

出售塑料回收厂

科特迪瓦塑料回收造粒线反馈

科特迪瓦客户的反馈是,塑料回收造粒线运行良好。客户使用该机器将废旧HDPE瓶加工成高质量的塑料颗粒。

硬质塑料回收厂发往阿曼

阿曼客户想要回收PP电池壳,所以我们为他们定制了塑料回收清洗线。该机器已运往阿曼客户的塑料回收工厂。

塑料废物回收机械制造商

作为专业的塑料废弃物回收机械制造商,我们一直致力于提供高效可靠的解决方案,帮助客户实现废旧塑料的回收再利用。

如果您对我们的产品有任何疑问或需要更多详细信息,请随时与我们联系。您可以在我们的网站上留言,我们的团队将很乐意为您提供专业的支持和个性化的解决方案,以满足您的特定需求。