Shuliy’s EPE EPS foam granulating line is a comprehensive solution designed to recycle and process waste EPE and EPS foam materials. This plastic foam pelletizing line includes several key machines, each carefully designed to convert waste foam into valuable plastic pellets. Let’s dive into the specifics of each foam recycling machine to learn about the entire production process, structure, and benefits of the pelletizing line.

What Are EPE And EPS Foams?

EPE stands for Expanded Polyethylene Foam. It is a lightweight, flexible foam that is commonly used for packaging, protection, and insulation. EPE foam has excellent cushioning properties, so it is often used to package fragile items and as insulation in construction and engineering.

EPS stands for Expanded Polystyrene. EPS foam is a hard but lightweight foam widely used in packaging, construction, and manufacturing. It is also known as white styrofoam and is commonly used to make insulated cups, boxes, and insulation panels for building exteriors.

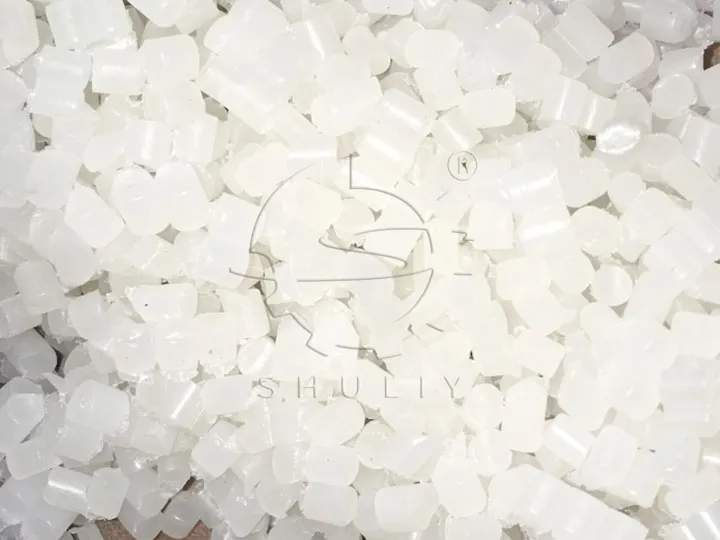

Final Plastic Pellets

The final product of the EPE EPS foam granulating line is foam granules. Foam granules are a versatile material that can be used for packaging materials such as glassware, electronic equipment, etc., filling materials, and insulation materials.

Advantages of Foam Recycling Machine

- Diversified pelletizing solutions: Depending on different EPE and EPS materials, we offer a variety of granulation solutions to ensure that each material can be optimally processed, thus improving production efficiency and product quality.

- Comprehensive recycling solutions: In addition to pelletizing, we also offer a variety of recycling solutions such as EPS hot melt and cold press. The EPS hot melting machine can melt and extrude EPS foam into ingot blocks, while the styrofoam compactor can crush and compress EPS foam into blocks, which effectively reduces the volume of the foam and facilitates storage and transportation.

Plastic Pelletizing Process

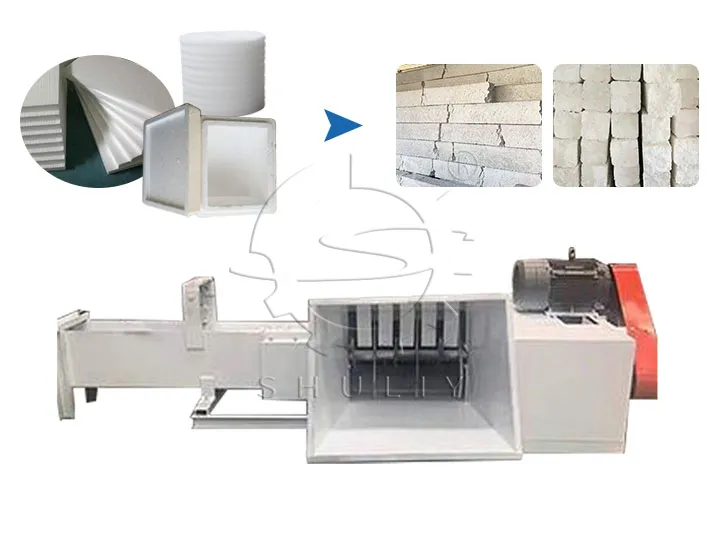

EPS and EPS are made of different materials and are pelletized differently; EPS is a slightly harder material, so it needs to be crushed into small pieces with a styrofoam shredder, then into an EPS pelletizer to be heated, melted, and extruded into long strips, which are then cut into pellets. EPE is a lighter material and the design of the EPE granulator is different. The machine has an automatic feeding device and the EPE material can be pelletized directly.

Foam Recycling Pelletizing Video

EPE EPS Foam Granulating Line Equipment

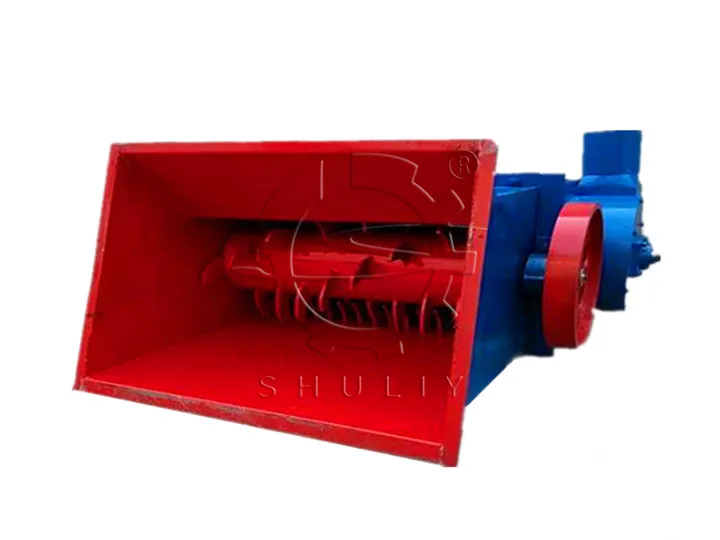

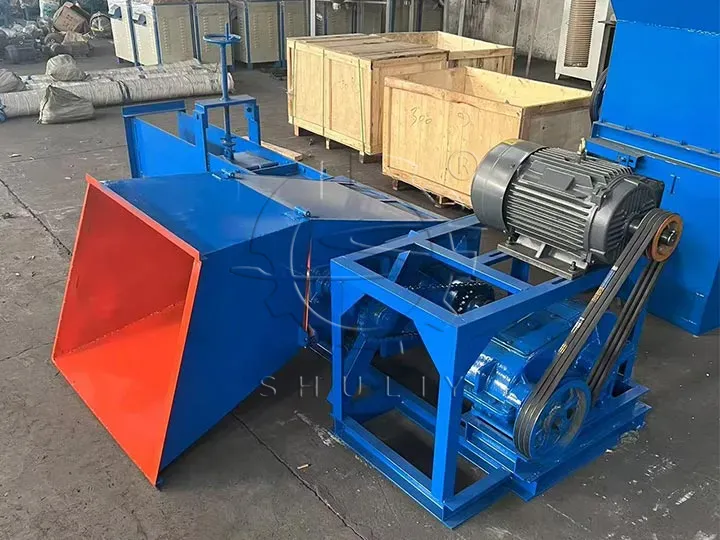

EPS foam shredder: The styrofoam shredder is used to crush large pieces of EPS foam into smaller pieces for subsequent granulation.

The machine has an output of 250 -500 kg/h. It is usually equipped with a fan or blower to transport the ranked blocks to the next step.

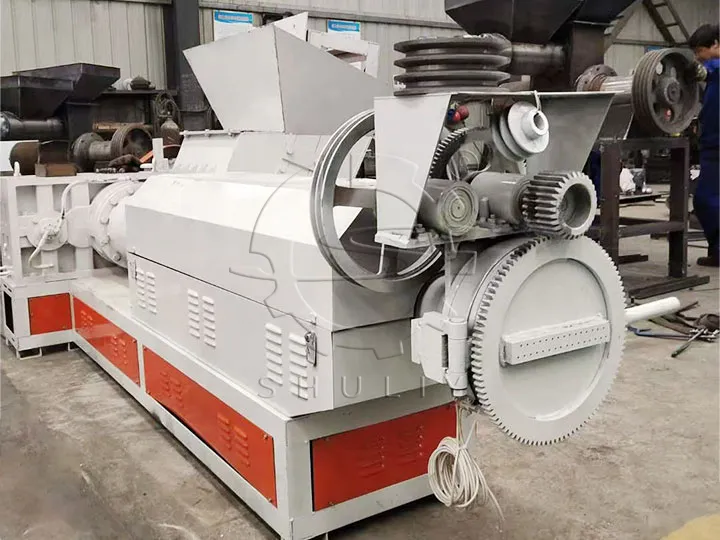

EPS pelletizing machine: The machine is important for processing EPS foam. After the crushed foam blocks enter the machine, they are heated, melted, and then extruded from the die head into long continuous plastic strips.

The EPS pelletizer extrudes pellets with a size of 3mm*4mm in length, and the main and auxiliary machines are heated by heating coils.

EPE styrofoam pelletizing machine: This plastic foam granulator is the key equipment of the plastic foam pelletizing line, it can heat and melt the foam, then extrude the long strip through the die head, which is easy to cut into small pellets.

The model of this plastic recycling machine is SL-160, the capacity is 150-200kg/hour, the power is 30kw, and it is heated by the heating ring.

Cooling tank: Used to cool and cure long strips of plastic, and then they enter the pellet cutting machine. The usual length is 3 meters, customer can customize it according to the actual situation.

Pellet cutting machine: This plastic recycling machine is used to cut long strips of cooled plastic into plastic granules, the size of which can be adjusted according to requirements.

Two Types of Foam Compactors

Shuliy Machinery offers two types of foam compactors, vertical and horizontal. EPS foam compactors are great for recycling foam, which is large but light and takes up a lot of space. This equipment can compress the foam into blocks, which is easy to store and transport, saving cost. This densifier machine has a compression ratio of 40:1, a simple structure, and is easy to operate.

Plastic Foam Granulator

In this EPE EPS foam granulating line, there are two kinds of Plastic foam extruders to choose from, EPE granulators and EPS pelletizers, customers can choose according to the raw materials.

Styrofoam Recycling Machine For Sale

As a professional foam recycling machine manufacturer, we are committed to providing efficient and reliable foam recycling solutions. Designed to process various types of foam, including EPS, EPE, and EPP, our machines can efficiently compress, melt, and regenerate waste foam into reusable materials. If you are interested in our EPE EPS foam granulating line or any plastic recycling machine, you can leave a message on our website and we will contact you as soon as possible.