As a professional egg tray machine supplier, we offer efficient, stable, and customizable egg tray production lines to help customers turn waste paper into recyclable molded pulp products, improving production efficiency and product value.

We focus on delivering high-efficiency, energy-saving, and tailor-made egg tray production solutions. Whether you are a start-up packaging business or an established factory looking to expand capacity, we can customize a complete solution based on your raw materials, plant layout, and budget—covering design, manufacturing, installation, and after-sales support—to help you start production easily and achieve a quick return on investment.

What Is an Egg Tray Production Line?

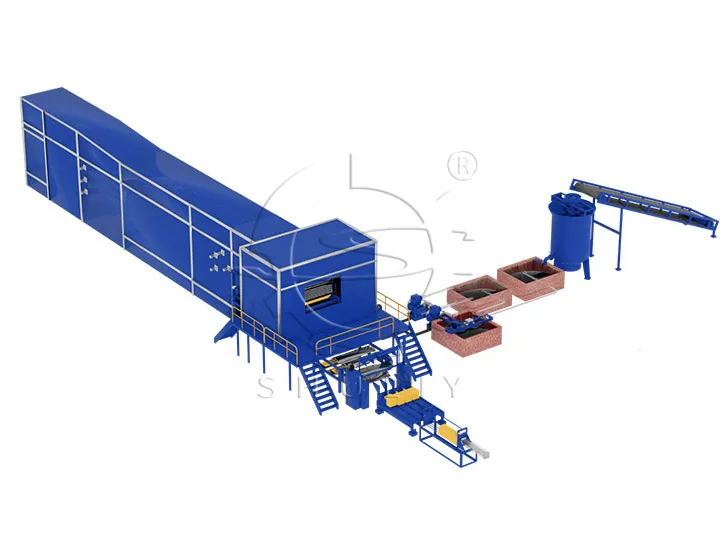

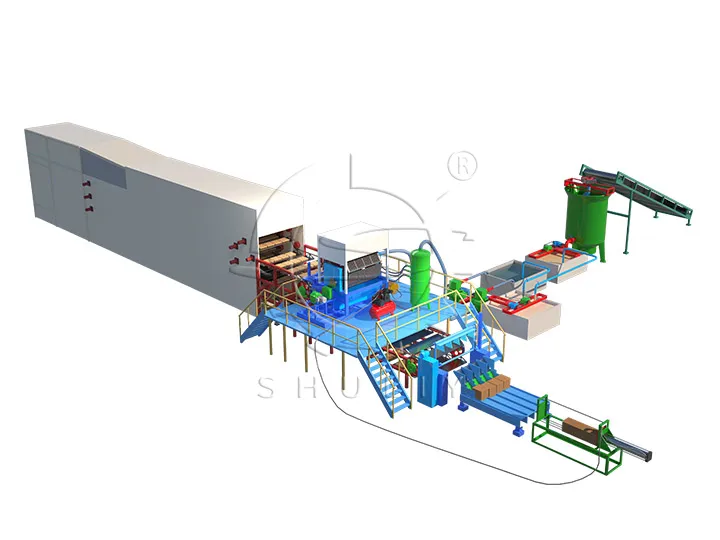

An egg tray manufacturing plant is an automated system that transforms waste paper pulp into egg trays and other pulp molded products. The complete line generally includes:

- Pulping system

- Egg tray forming machine

- Egg tray drying equipment

- Hot pressing (optional)

- Packing system

We provide tailored solutions to fit the needs of various customers, from start-up recycling plants to small packaging workshops and large-scale poultry farms.

Raw Materials and Finished Products

Applicable Raw Materials:

Our egg carton production line is designed to handle a wide range of raw materials, including:

- Waste newspapers

- Corrugated cardboard

- Used books

- Industrial paper scraps

This allows clients to use locally sourced waste paper instead of expensive virgin pulp, reducing production costs.

Types of Finished Products:

By changing molds, the egg tray production line can manufacture a variety of pulp molded items, such as:

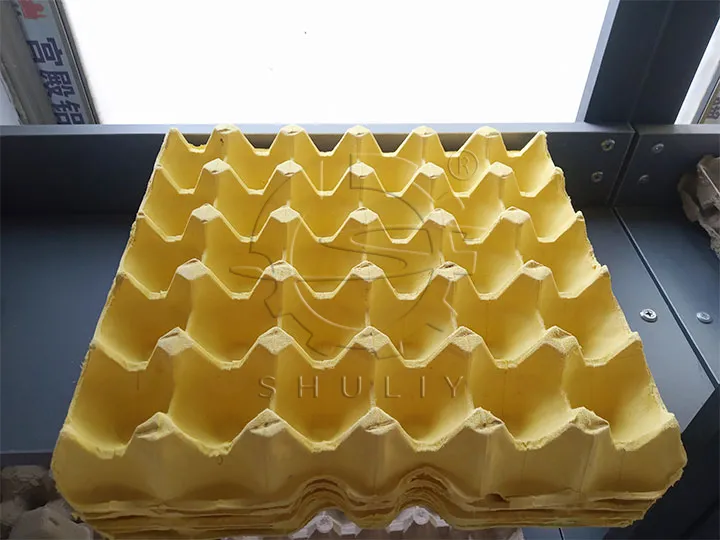

- Egg trays: Commonly in 30-cell configuration, suitable for eggs, duck eggs, quail eggs, etc.

- Fruit trays: For packaging apples, kiwis, and other fruits

- Coffee cup holders: Widely used in takeaway beverage packaging

- Industrial trays: For electronics, hardware, and other fragile items

Product Color:

The color of the final products depends on the color of the raw material pulp. Common colors include grey, yellow, and light brown. Color additives can be used if needed.

We support custom mold design, thickness adjustment, and product specification matching, ensuring the output meets your specific market needs.

Egg Tray Production Line Video

Egg Tray Production Process

The egg tray production line typically follows these steps:

1, Paper Pulping Machine

Waste paper is mixed with water and stirred in the paper pulper to produce a uniform pulp.

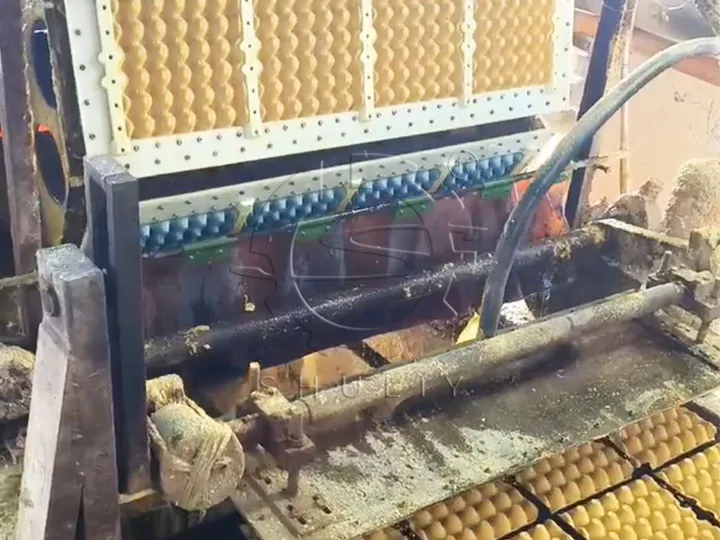

2, Tray Forming – Egg Tray Molding Machine

The pulp is formed into wet trays using vacuum suction and a metal forming mold, then transferred to a shaping mold of the egg tray molding machine.

3, Egg Tray Drying System

Wet pallets are dried by hot air metal drying channels or natural drying to ensure pallet strength.

4, Hot Pressing (Optional)

Enhances the appearance and smoothness of the trays, ideal for high-quality product demands.

5, Egg Tray Packing Machine

The dried trays are stacked and packed automatically or manually for storage and delivery.

Advantages of Egg Tray Manufacturing Plant

Lower Production Cost

- Uses waste paper (such as old newspapers and cardboard) as raw materials, which are widely available and inexpensive.

- The machine has high adaptability to different paper materials, efficiently pulping and forming trays to maximize raw material use.

Wide Production Capacity Options

- Available capacities range from 1000 pcs/h to 8000 pcs/h, covering small startups to large automated factories.

- We can recommend the right configuration based on the customer’s budget and site conditions.

Strong Customizability

- By changing molds, different tray types can be produced, such as egg trays, fruit trays, coffee cup trays, and industrial packaging trays.

- We offer mold customization to meet diverse market needs.

Comprehensive After-Sales Service

- We provide installation guidance, operator training, after-sales support, and remote technical service.

- One-year warranty on core components and lifetime technical support.

Short Payback Period

- Egg trays, fruit trays, and cup trays are in steady demand across agriculture, e-commerce, food delivery, and other industries.

- Most customers report recovering their investment within 6 to 12 months after production starts.

FAQs of Egg Tray Production Line

Can the egg tray machine produce trays of different sizes?

Yes, it can. You only need to customize the mold according to your requirements.

Can the egg trays be made in different colors?

Yes, by adding pigments to the pulp, you can change the color of the trays.

Can the thickness of egg trays be adjusted?

Yes. By adjusting pulp concentration and suction time, the product thickness can be controlled.

How much factory space is needed and how should the layout be arranged?

After the order is confirmed, we will design the layout drawing based on the customer’s requirements.

Do you provide installation service?

Yes. We offer on-site installation or remote video guidance.

What We Offer

As a professional egg tray making machine supplier, we go beyond just selling machines. We provide complete solutions:

- Free layout design and production planning

- Mold customization for various tray types and sizes

- One-stop purchase support (pulping, forming, drying, hot press, packing equipment)

- Installation and operator training

- Warranty, spare parts, and lifelong technical support

Egg Tray Production Line – General Technical Parameters

| Item | Specification |

| Production Capacity (pcs/h) | 1,000 – 8,000 pcs/h (customizable) |

| Raw Materials | Waste newspapers, books, cardboard, office paper, etc. |

| Available Product Types | Egg trays, fruit trays, coffee cup holders, industrial trays |

| Color Customization | Supported (add pigment to the pulp to change color) |

| Drying Options | Natural drying / Metal drying line / Brick kiln (optional) |

| Mold Replacement | Supported – one machine can use different molds |

| Product Customization | Available – size, color, and capacity can be customized |

| Installation Support | Remote or on-site service, with layout and operation guidance |

The egg tray production line is an efficient and eco-friendly solution for turning waste paper into high-demand packaging products. Whether you are starting a new recycling business or upgrading an existing plant, we can provide complete solutions tailored to your needs.

If you’re interested in learning more, feel free to contact us for detailed quotations, layout plans, and professional advice.

We look forward to working with you!