EPS granulator is a machine used to process EPS foam material. EPS foam is a common plastic foam commonly used in packaging, building insulation, art, and decorative applications. The main function of the EPS pelletizing machine is to process waste EPS foam material into small pellets for recycling and reuse. The output of the machine ranges from 150kg/h to 375kg/h.

EPS Foam Pelletizing Machine Working Video

Applications for EPS Pelletizing Machine

EPS granulator is suitable for a wide range of foam products made from EPS foam material. EPS foam is a high-quality material widely used in the field of packaging, which is often used as a cushioning package for all kinds of products, including household appliances, precision instruments, glassware, ceramics, and handicrafts.

In addition, fast food boxes, insulation boxes, and other common products are also widely manufactured with EPS materials. EPS granulator helps to convert these waste EPS foam products into useful recycled pellets.

Features of Plastic Foam Extruder

- High-efficiency screw extrusion system enables continuous production of EPS granulators with outputs of 100kg and more per hour.

- The automatic control system automates the whole process, reduces manual intervention, and improves efficiency.

- The main parts are made of high-quality alloy steel or stainless steel, which is wear-resistant and corrosion-resistant, prolonging the life.

- Widely used in all kinds of EPS foam, such as packaging, thermal insulation materials, and waste household appliances filler.

- The die head adopts an electric mold design, which realizes no stoppage for screen changing and improves production efficiency.

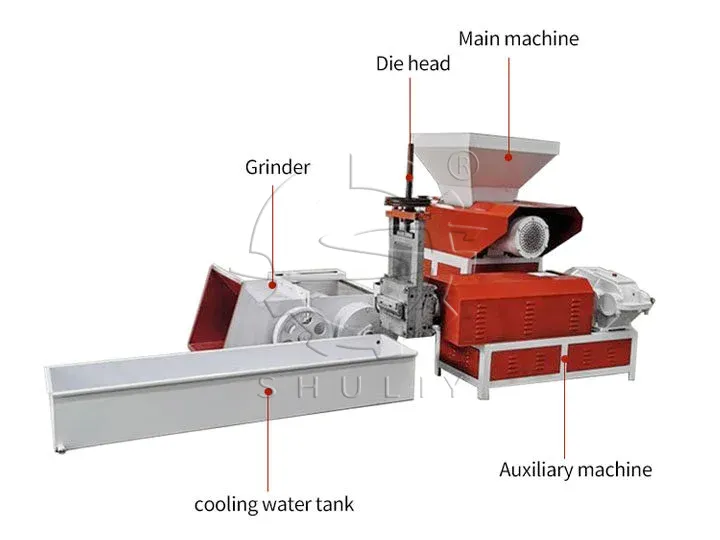

Structure of EPS Granulator

The plastic foam extruder consists of a main machine, auxiliary machine, feed inlet, motor, mold head, grinder, barrel, screw, control cabinet, and heating device. One of the mold heads is a meshless mold head, which eliminates the need for a filter screen. Electromagnetic heating, fast heating speed.

How Do You Pelletize Plastic Foam?

A complete plastic foam pelletizing line consists of a conveyor, foam crushing machine, EPS pelletizing machine, cooling tank, plastic granules cutter, storage bin, and so on. The EPS granulation workflow is mainly divided into the following steps:

Grinding Pre-processing

EPS foam, due to its large size and low density, first needs to be crushed into small pieces using a foam shredder for subsequent processing.

Feed and Compression

The crushed small pieces of EPS foam are transported to the EPS granulator, where they are compressed and heated through the screw system to soften and melt the foam.

Melt Extrusion

The molten EPS material is extruded from the mold, driven by the screw, to form a continuous strip.

Cooling and Curing

The extruded strip is rapidly cooled and cured in a water bath to ensure its shape stability.

Pelletizing and Moulding

The cooled strip enters the pelletizer and is cut into small uniform particles, and finally, the finished product of recycled EPS granules is obtained.

Specifications of EPS Pelletizing Machine

- Double reducer

- Capacity (KG/H): 150-175

- Main motor (KW): 15

- Double reducer

- Capacity (KG/H): 200-225

- Main motor (KW): 18.5

- Double reducer

- Capacity (KG/H): 275-300

- Main motor (KW): 18.5

- Double reducer

- Capacity (KG/H): 325-375

- Main motor (KW): 22

Export Case of EPS Foam Granulator

Recently, a client from Suriname placed an order for two foam granulators from our company, designed for recycling EPE and EPS materials respectively. Due to slight differences in the granulation processes for these two materials, separate granulators were required.

The EPS granulator model selected by the client boasts a production capacity of 150-200 kg/h, features a double reducer for enhanced stability, and is equipped with an electric mold and a no-stop screen-changing system, ensuring continuous and efficient operation. This case highlights our commitment to providing tailored solutions for diverse recycling needs worldwide.