In the plastic processing industry, the waste plastic granulator machine is a commonly used equipment for processing waste plastics into granular materials for reuse. Adjusting the discharge speed of plastic granulation equipment is crucial for production efficiency and product quality. This article will discuss how to correctly adjust the discharging speed of plastic pelletizing recycling machines to improve production efficiency and reduce production costs.

The Importance of Discharge Speed

In the process of plastic granulation, the discharging speed directly affects the shape, size, and quality of the granules. Too fast discharging speed may lead to uneven, coarse, and fine particles, and even cause equipment clogging; while too slow discharging speed will reduce production efficiency and increase production costs.

Method of Adjusting The Discharge Speed

Adjusting The Feed Volume

The discharging speed of the waste plastic granulator machine is affected by the feeding amount. By adjusting the feeding quantity, the discharging speed can be adjusted indirectly. Increasing the feeding quantity can increase the discharging speed while decreasing the feeding quantity will reduce the discharging speed. Therefore, when adjusting the discharging speed, the adjustment of the feeding quantity should be paid attention to first.

Adjustment of Screw Speed

The discharge speed of the plastic pelletizing recycling machine is also affected by the screw speed. Increasing the screw speed can speed up the movement of plastic in the barrel, thus increasing the discharging speed; while decreasing the screw speed will reduce the discharging speed. Adjusting the screw speed is one of the effective methods to directly adjust the discharging speed.

Adjustment Of Extrusion Pressure Of Waste Plastic Granulator Machine

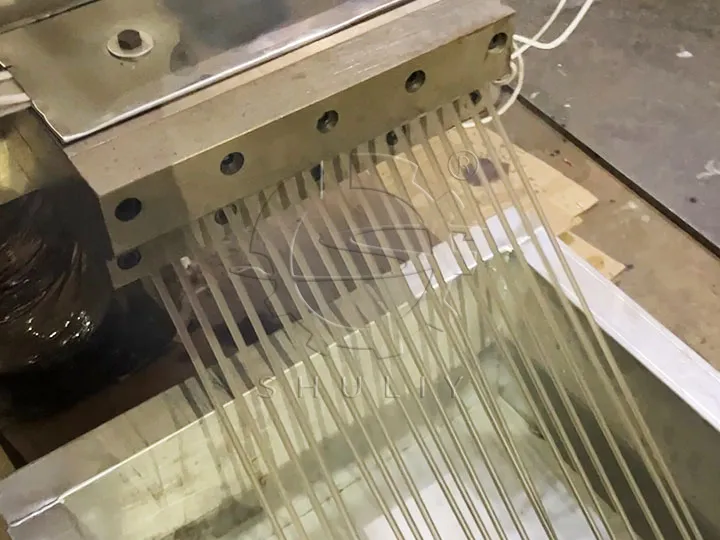

Extrusion pressure is one of the important parameters affecting the discharging speed of waste plastic granulator machines. Increasing the extrusion pressure can enhance the extrusion strength of plastic in the barrel, thus increasing the discharge speed; reducing the extrusion pressure will reduce the discharge speed. Therefore, when adjusting the discharging speed, it is necessary to pay attention to the appropriate adjustment of extrusion pressure.

Precautions For Adjustment

Stability First

When adjusting the discharging speed, attention needs to be paid to maintaining the stability of the equipment. Too fast discharging speed may lead to unstable operation of the equipment, or even cause failure, affecting production efficiency and product quality.

Real-time Monitoring

When adjusting the discharging speed, the operating status of the equipment and product quality should be monitored in real-time. Through real-time monitoring, problems can be found and solved in time to ensure the stability of the production process and the consistency of product quality.

Conclusion

Adjusting the discharging speed of waste plastic granulator machines is one of the keys to improving production efficiency and ensuring product quality. By reasonably adjusting the feed volume, screw speed, and extrusion pressure, as well as paying attention to maintaining the stability of the equipment and real-time monitoring of the production process, you can effectively improve the discharge speed of the plastic granulation equipment, to achieve the efficient operation of the production.