Dry ice blocks production line is a complete system designed to process liquid carbon dioxide into solid dry ice blocks. The entire production line starts with dry ice pelletizing, followed by block pressing, automatic conveying, and final packaging. It enables continuous and stable production of dry ice blocks and is widely used in cold chain logistics, food processing, industrial cooling, and related fields.

Why Invest in a Dry Ice Blocks Production Line?

For enterprises that require large quantities or continuous use of dry ice blocks, in-house production offers significant economic and operational advantages. Investing in a complete production line means you can:

- Reduce Costs: In the long run, the cost of producing your own dry ice is much lower than continuously purchasing it, leading to significant savings.

- Increase Efficiency: An automated production line greatly reduces manual labor, enabling 24-hour continuous production with stable output and high efficiency.

- Ensure Supply: Eliminate reliance on external suppliers and produce on-demand, avoiding business disruptions caused by supply interruptions.

- Control Quality: Control the purity and density of dry ice from the source, ensuring high-quality, high-density products that last longer.

Optimized Features of Our Dry Ice Blocks Production Line

Well-Matched Integrated Process

The pelletizing, block pressing, conveying, and packaging stages are well coordinated, reducing intermediate downtime and ensuring a continuous and stable production process.

Flexible Capacity Configuration

Different models of dry ice pellet machines and block press machines can be selected according to actual production requirements, making the line suitable for dry ice block projects of various scales.

Consistent Dry Ice Block Formation

The pressing process is stable, with controllable block size, thickness, and density, which facilitates storage, transportation, and end use.

Reduced Manual Handling and Material Loss

Conveying systems connect each production stage, minimizing manual handling and helping reduce dry ice sublimation losses.

Easy Installation and Future Expansion

The compact line layout allows for convenient installation and commissioning, with reserved space for future capacity upgrades.

Wide Range of Applications

Suitable for cold chain logistics, pharmaceutical transportation, industrial cooling, dry ice blasting, and other dry ice block applications.

Overall Configuration of the Dry Ice Blocks Production Line

This dry ice manufacturing plant consists of several core machines working together. Each process is smoothly connected, with a compact structure and a clear operating flow, making daily operation and maintenance convenient.

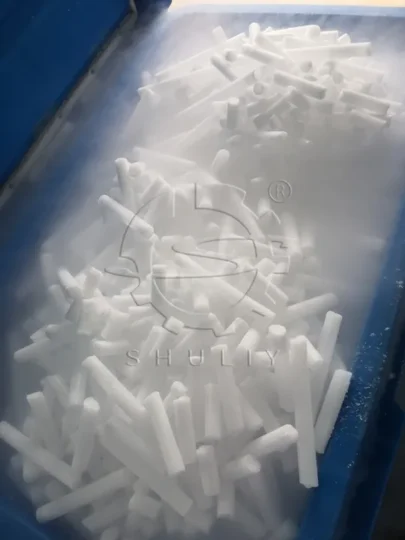

Dry Ice Pelletizing Process

The first step of the production line is dry ice pellet production. Liquid carbon dioxide rapidly expands and cools inside the dry ice pellet machine, forming uniform dry ice pellets. This stage provides a stable and consistent raw material for the subsequent block pressing process, as pellets are well suited for compression and shaping.

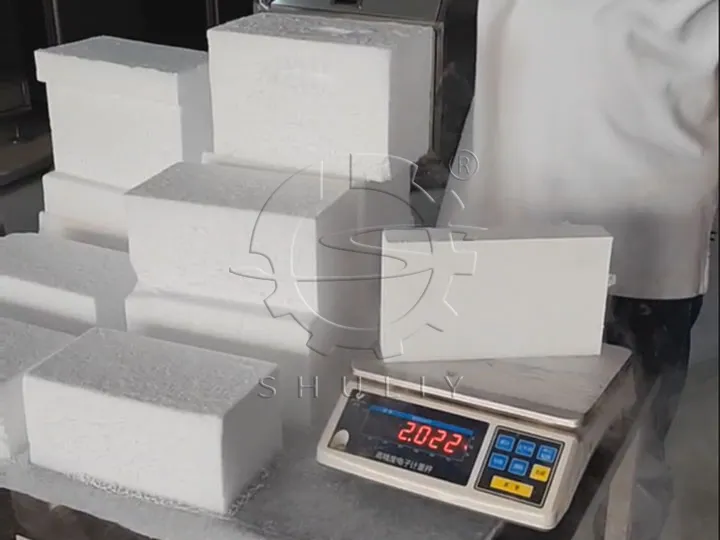

Dry Ice Block Pressing Process

After pelletizing, the dry ice pellets are fed into the dry ice block making machine, where they are compressed into regular-shaped dry ice blocks. The block press can produce dry ice blocks in different sizes and thicknesses according to production requirements. The pressing process is stable, and the finished blocks have high density and good structural integrity, making them suitable for storage and transportation.

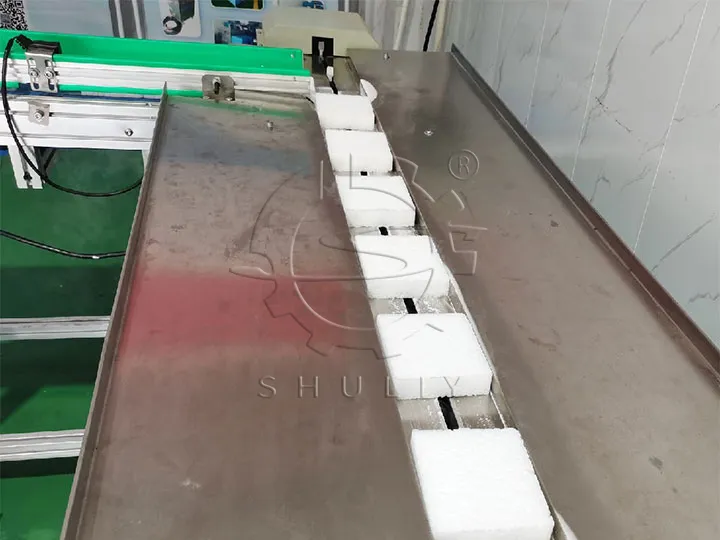

Conveying System and Automatic Packaging

The formed dry ice blocks are automatically transferred to the packaging system through a conveying unit, reducing manual handling and minimizing material loss. The packaging method can be configured based on customer needs, allowing the dry ice blocks to be prepared for short-term storage or direct delivery. The conveying and packaging stages are smoothly integrated to help improve overall production efficiency.

Dry Ice Blocks Production Line Operation Video

What Are the Main Application Areas for Dry Ice Blocks?

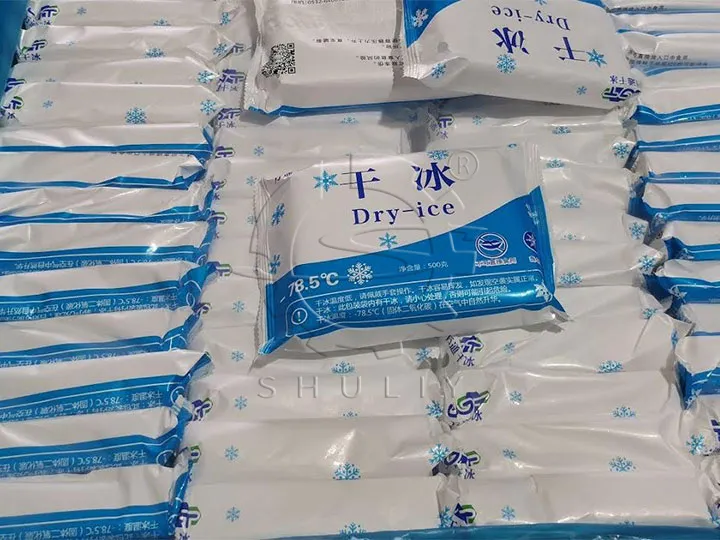

With its ultra-low temperature of -78.5°C and residue-free properties, dry ice plays an indispensable role in many fields.

- Cold Chain Logistics: It is the ideal refrigerant for transporting temperature-sensitive items like vaccines, pharmaceuticals, and high-end fresh foods.

- Food & Catering: Used for food refrigeration in airline catering, rapid cooling during food processing, and making ice cream and specialty drinks.

- Industrial Applications: Serves as a consumable for dry ice blasting to clean precision molds, equipment, and more.

- Medical & Scientific Research: Used for the long-term cryogenic preservation of plasma, biological samples, and pharmaceuticals.

- Stage Effects: Creates spectacular fog and cloud effects for entertainment events.

Contact us for Dry Ice Blocks Production Line details

The dry ice blocks production line integrates dry ice pelletizing, block pressing, conveying, and packaging into a complete and efficient production process. With a clear structure and stable operation, it provides a reliable solution for dry ice block manufacturing.

For more information on different capacity options and technical specifications, please feel free to contact us for a detailed dry ice block production line solution.