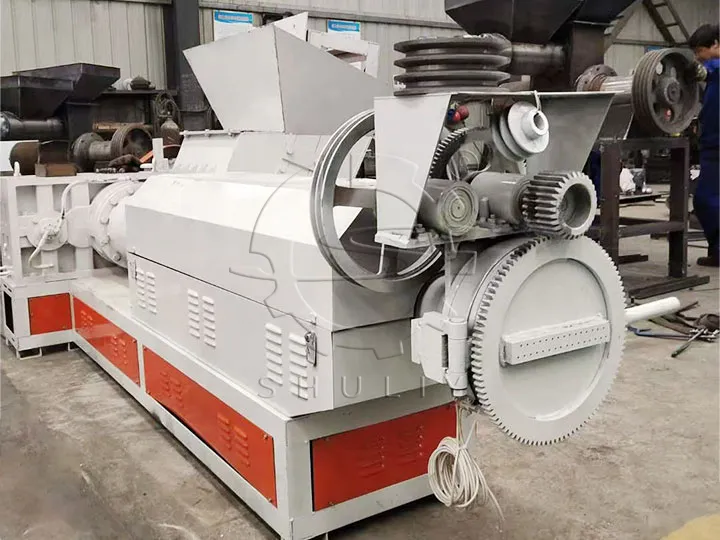

EPE styrofoam pelletizing machine is a specialized equipment for converting waste EPE polystyrene foam material into granular raw material. This advanced technology enables the recycling of waste EPE materials, which not only helps the environment but also realizes the effective recycling of resources. In this article, we will discuss in depth the working principle of EPE granulators, application areas, etc.

Characteristics Of EPE Polystyrene

EPE polystyrene is a lightweight, soft, and insulating foam material commonly used for packaging and protection. However, discarded EPE materials are usually difficult to dispose of, and EPE styrofoam pelletizing machines have been created to solve this environmental challenge.

Working Principle Of EPE Styrofoam Pelletizing Machine

The EPE granulator converts waste EPE material into pellets through a series of mechanical processing steps. Firstly, the waste material is collected and the waste foam is put into the EPE styrofoam pelletizing machine, where it is first chopped into small pieces by a cutting system. Next, through an extrusion system, the chopped EPE material is heated and extruded to form a pelletized recycled feedstock.

Working Video Of EPE Granulator

Areas Of Application

EPE granulator is widely used in various fields. These recycled pellets can be used to make new EPE products, such as packaging materials, insulation materials, and so on. In addition, EPE pellets can be used for filling materials, such as filling toys or furniture.

EPE styrofoam pelletizing machine, as an advanced recycling technology, provides a sustainable recycling outlet for waste EPE materials. By converting these materials into granular raw materials, we are not only helping the environment but also achieving effective recycling of resources.