The waste plastic pelletizing line is a crucial industrial process that transforms waste plastics into reusable pellets. The workflow of this production line is both intricate and pivotal, directly impacting the quality and usability of recycled plastics. This article will delve into the process of the plastic granules extrusion line, revealing the significance of each key step.

Waste Plastic Pelletizing Line Workflow

Step 1: Raw Material Collection

The process commences with the collection of raw materials, encompassing a variety of plastics, including films or rigid plastics. These discarded materials serve as the foundation for the subsequent stages of the waste plastic pelletizing line.

Step 2: Shredding into Small Fragments

The collected plastics, whether in the form of films or rigid plastics, undergo fragmentation using a plastic shredder recycling machine. This crucial step reduces the plastics into smaller, manageable fragments, enhancing the efficiency of the overall process.

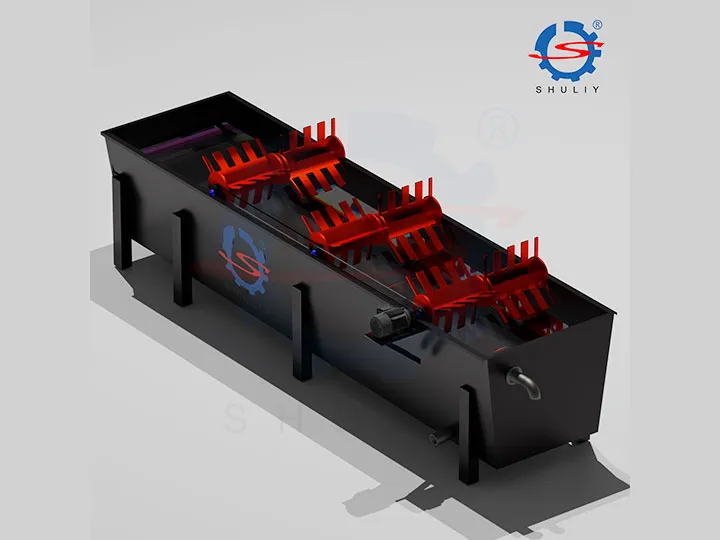

Step 3: Washing and Drying

Subsequent to the shredding process, the plastic fragments proceed to plastic washing tanks. Here, a thorough washing operation takes place to remove impurities, ensuring the plastic is prepared for further processing in a pristine condition. After cleaning, the material enters a plastic dewatering machine to remove water, ensuring that the plastic is dry and in condition for pelletizing.

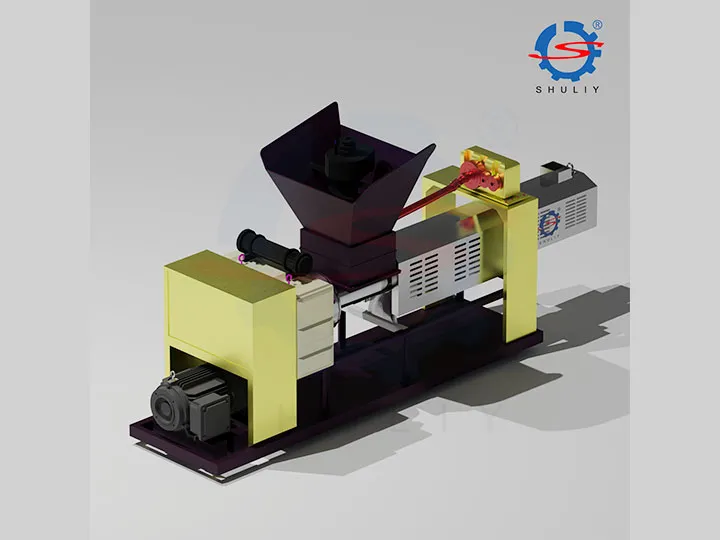

Step 4: Melting and Extrusion

The cleaned plastic debris enters a waste plastic granules making machine where it is melted and extruded to form long strips of plastic. This is a key intermediate step from waste to reusable material.

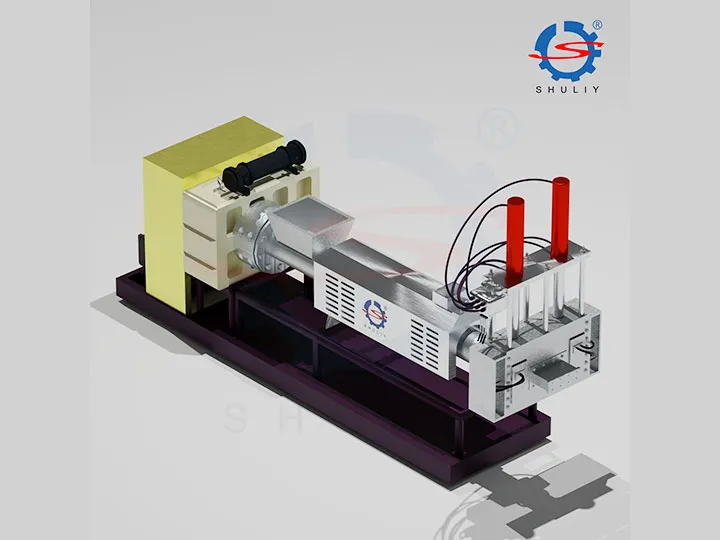

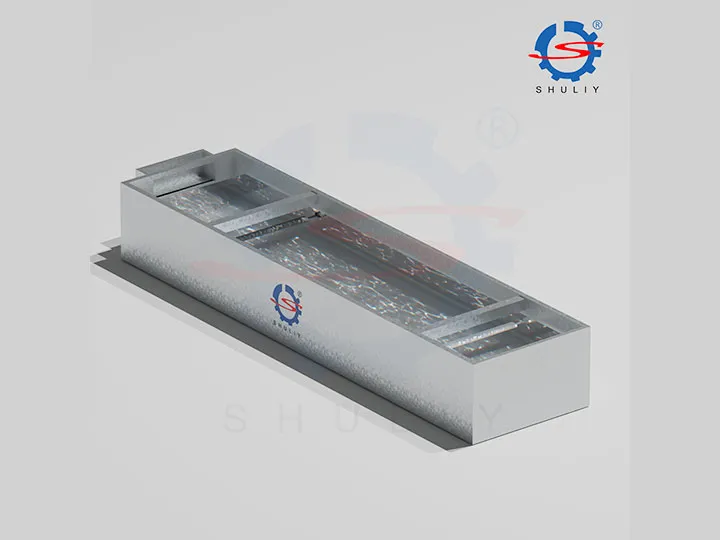

Step 5: Cooling And Cutting

The extruded plastic strands move into a cooling tank, where they undergo a crucial cooling and solidification process. This step ensures the plastic strands solidify into a stable form, laying the groundwork for the subsequent granulation. The cured plastic lengths are then conveyed to a plastic granules cutting machine where they are precisely cut to form uniformly sized pellets. This granulation process is critical to producing high-quality plastic pellets for a variety of applications.

Step 6: Packaging and Storage

The final stage of the waste plastic pelletizing line involves the packaging of the produced pellets. After packaging, the pellets are stored in the appropriate conditions and await shipment to various industries, such as manufacturing, for reuse.

Conclusion

The workflow of the waste plastic pelletizing line constitutes a coordinated and complex system, involving multiple key steps, each profoundly influencing the quality of the end product. By understanding and optimizing each stage, manufacturers can produce high-quality, reusable plastic pellets.