Laini zetu za chembechembe za filamu za PP PE ni mojawapo ya suluhu bora zaidi za kuchakata plastiki kutoka kwa Mashine ya Shuliy. Iwe malighafi yako ni PP, PE, au filamu nyingine yoyote ya plastiki, laini yetu kamili ya kuchakata filamu taka inaweza kukidhi mahitaji yako ya kuosha plastiki au kuichakata kwenye pellets za plastiki, ambayo inaweza kukuletea faida kubwa.

Mstari huu wa kuchakata filamu za plastiki ni mfumo changamano unaojumuisha baadhi ya mashine muhimu za kuchakata tena plastiki, kila mashine ina jukumu muhimu katika kuhakikisha kwamba matokeo ya mwisho ya pellets za plastiki ni za ubora wa kipekee. Uwezo wetu wa laini hii ni 100-500kg/h. Bila shaka, tunaweza pia kutoa huduma maalum kulingana na mahitaji yako.

Hapa tutakujulisha jinsi ya kusindika filamu ya plastiki kwenye vidonge vya plastiki na ni vifaa gani vinavyohitajika kwa mchakato huu.

Je! Mstari wa Granulation wa Filamu ya PP PE ni nini?

Laini ya chembechembe ya filamu ya PP PE ni suluhisho kamili la kuchakata tena iliyoundwa mahsusi kusindika na kutumia tena taka taka filamu. Laini huchakata taka za filamu za plastiki kuwa pellets za plastiki zinazofanana kupitia msururu wa michakato kama vile kusagwa, kuosha, kuondoa maji, kuyeyuka, kutoa nje na kukata. Chembechembe hizi zinaweza kutumika kama malighafi kutengeneza tena bidhaa mbalimbali za plastiki.

Kama mtengenezaji mwenye uzoefu wa kuchakata plastiki, kiwanda chetu cha kuchakata tena plastiki kimepokea kutambuliwa kutoka kwa wateja kutoka kote ulimwenguni, kama vile Saudi Arabia, Msumbiji, Oman, Ghana, Ujerumani, Nigeria, Ethiopia, Malaysia, Côte d'Ivoire, Kenya, na kadhalika. Tumejitolea kuwapa wateja vifaa vya kuchakata vyema na vya kutegemewa na kuboresha teknolojia na kiwango cha huduma mara kwa mara. Bidhaa zetu ni pamoja na seti kamili ya vifaa vya kuchakata tena kama vile shredder ya taka ya plastiki, mashine ya kuosha plastiki, mashine ya kukausha plastiki, mashine ya kuchakata pelletizing ya plastiki, na kadhalika, ambayo inaweza kukidhi mahitaji ya wateja tofauti.

Utumiaji wa Mstari wa Urejelezaji wa Plastiki wa Kuchakata

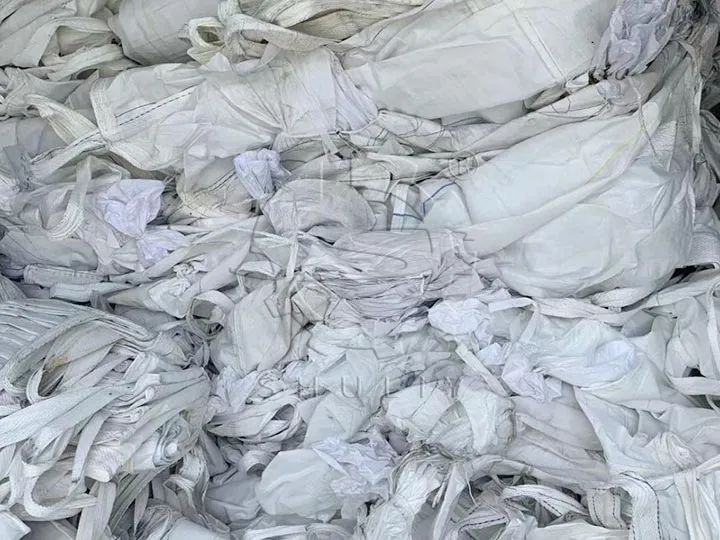

Laini ya granulation ya filamu ya PP PE inafaa kwa malighafi mbalimbali ikiwa ni pamoja na filamu za plastiki, mifuko ya PP iliyosokotwa, mifuko ya saruji, filamu za kilimo na chafu, filamu za viwandani za ufungaji, filamu za kupunguza joto, filamu za kunyoosha, mifuko ya takataka, na filamu za Bubble. Malighafi hizi kwa kawaida huwa bidhaa za plastiki zinazoweza kutupwa ambazo, zisiposhughulikiwa ipasavyo, zinaweza kusababisha hatari kubwa za kimazingira kama vile uchafuzi wa mazingira na upotevu wa rasilimali.

Tunaweza kubinafsisha suluhisho linalofaa kwa wateja wetu kulingana na aina na wingi wa malighafi na kiwango cha uchafu. Baada ya mawasiliano kamili na mteja, tutarekebisha kwa urahisi usanidi wa vifaa ili kuhakikisha kuwa mchakato mzima wa kuchakata plastiki ni mzuri na wa kiuchumi.

Kwa mfano, kwa aina tofauti za filamu, tunaweza kuandaa mashine za kusaga na kuosha zinazolingana; kwa malighafi chafu, tunaweza kuongeza michakato mingi ya kusafisha na kusafisha ili kuhakikisha usafi wa bidhaa zilizokamilishwa. Kwa kuongeza, tunaweza pia kurekebisha uwezo wa laini ya granulation ya filamu ya PP PE kulingana na mahitaji ya uzalishaji wa mteja, ili kukidhi mahitaji ya makampuni ya biashara ya ukubwa wote.

Bidhaa za Mwisho

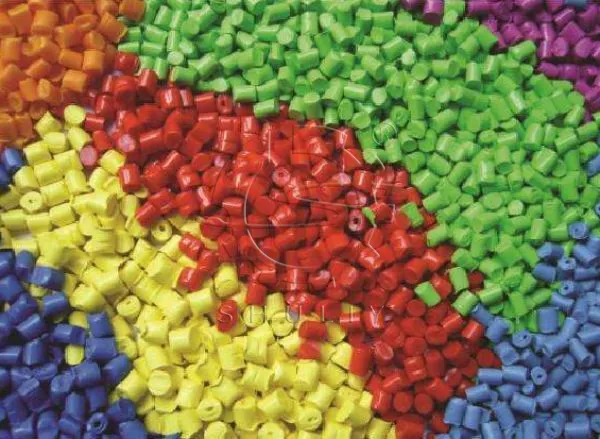

Bidhaa iliyokamilishwa ya laini ya granulation ya filamu ya PP PE ni CHEMBE za plastiki zilizosindikwa za hali ya juu ambazo zina ukubwa sawa na mali bora ya mwili. Pellet hizi hutumika sana katika utengenezaji wa bidhaa mbalimbali za plastiki, kama vile vifungashio, mabomba, karatasi, na bidhaa za nyumbani. Kwa vile laini yetu ya kuchungia inaweza kuondoa uchafu na uchafu ipasavyo, pellets zilizorejeshwa zinazozalishwa ni za ubora wa juu, na kuwapa wateja wetu malighafi ya ubora wa juu ambayo ni ya ushindani sokoni.

Video ya 3D ya Mstari wa Urejelezaji wa Filamu za Plastiki

Manufaa ya PP PE Film Granulation Line

Flexible Configurations: We offer flexible equipment configurations based on the type of feedstock, quantity, and degree of soiling to ensure that the recycling solution is maximized to meet the needs of the customer. Whether you need to adjust a single piece of equipment or optimize an entire granulation line, we can provide expert advice and solutions.

High-quality pellets produced: Our pelletizing systems produce high-quality plastic granules that can be used directly in the manufacture of new plastic products. Advanced technology and sophisticated equipment ensure that pellets are uniform and free of impurities, enhancing the properties and applications of recycled materials.

Vifaa vinavyoweza kubinafsishwa: Tunatoa anuwai ya vifaa vya hiari ili kukidhi mahitaji tofauti ya wateja. Iwe ni urekebishaji wa saizi ya skrini, uteuzi wa nyenzo za blade, au uboreshaji wa usanidi wa laini ya uzalishaji, tunaweza kubinafsisha kulingana na mahitaji ya mteja ili kuhakikisha kuwa kifaa kinachukuliwa kulingana na mazingira na malengo ya uzalishaji ya mteja.

Je! Ni nini kinachotumika kutengeneza Pellet za Plastiki?

Mchakato wa kuweka plastiki ni mchakato wa kubadilisha nyenzo za plastiki taka katika vidonge vya plastiki vya ubora wa juu, ambayo inahusisha hatua kadhaa muhimu, kutoka kwa kusagwa hadi kuhifadhi mwisho. Mitambo ya kuchakata tena plastiki kama vile vipasua vya plastiki, mashine za granula za plastiki, matangi ya kuoshea plastiki, na mashine zingine za kuchakata plastiki zote ni vifaa muhimu katika utengenezaji wa pellets za plastiki. Yafuatayo ni maelezo ya kina ya mstari huu wa granulation wa filamu ya PP PE:

Shredder ya plastiki

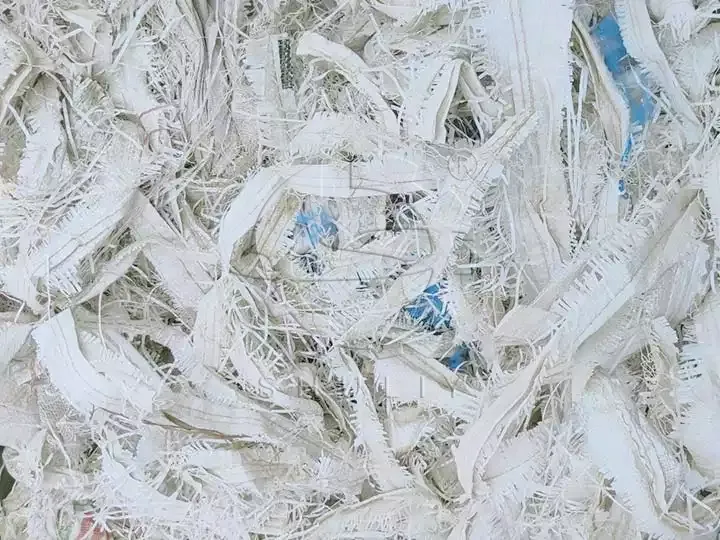

First, råvaror, such as plastic film and woven bags, are crushed through a plastic shredder. Detta steg hugger stora bitar plastmaterial i mindre bitar för att göra dem lättare att hantera.

Visu vya kuponda hutengenezwa kwa nyenzo 60Si2Mn, inayojulikana kwa kudumu na uwezo wa kufikia kukata kwa ufanisi. Wakati wa kusindika nyenzo za filamu, ukubwa wa skrini umewekwa kati ya 40-50mm, kuhakikisha ukubwa thabiti wa filamu iliyosagwa. Zaidi ya hayo, mipangilio ya mashine inaweza kubadilishwa kulingana na mahitaji ya mtumiaji, kutoa kubadilika na usahihi katika uendeshaji.

Tangi ya Kuosha ya Plastiki

The crushed plastic chips are further passed through a plastic washing tank to remove contaminants and impurities remaining on the surface of the material. The washing is done to ensure that the final output of plastic granules is of pure quality and suitable for remanufacturing.

Tangi letu fupi la kufulia lina urefu wa mita 5 na magurudumu mawili ya kichochezi kwa vifaa vidogo. Ikiwa una uwezo mkubwa, pia tuna mizinga ya suuza yenye urefu wa mita 15-20 na mita 30.

Kikausha Wima

After washing, the plastic goes into a vertical dryer, a step designed to remove moisture from the surface of the plastic. Drying is critical because moisture affects the quality and shape of the pellets. The dried plastic is easier to process and mold. The machine can be used with a horizontal dryer, the dehydration rate is 95%-98%.

Granulator ya Filamu ya Plastiki

The dried material will be fed into the plastic film granulator, which is the core part of the whole PP PE film granulation line. Inside the plastic granulator machine, the plastic films will be heated, melted, and then extruded through the die head to form high-quality plastic granules. The size and shape of this pellet can be adjusted as required.

Mfano wa pelletizer huitwa kwa kipenyo cha screw, na feeder ya kulazimishwa, njia ya kupokanzwa, na kichwa cha kufa kinaweza kuchaguliwa kulingana na mahitaji ya mteja.

Mashine ya kukata pellet

After pelletizing, long strips of pellets often need to be cut into consistent-sized granules for different applications. Pellet cutting machines are responsible for this task, ensuring that the final pellets meet specifications. The pellet cutting machine adopts a hard alloy hob, which is so durable that the blade only needs to be replaced once for every about 2000 tons of granules processed. The size of the pellets cut out is about 3mm, which can be adjusted according to customers’ requirements.

Bin ya Kuhifadhi Pellet ya Plastiki

The final output of high-quality plastic granules will be stored in a storage bin. This warehouse can be used for temporary storage of pellets pending sale or further processing. Correct storage conditions are important to maintain the quality of the pellets. We provide various sizes of plastic granule storage silos to meet various production needs.

Video ya Kazi ya Mstari wa Urejelezaji wa Filamu Takataka

Maelezo ya Mashine ya Usafishaji Filamu za Plastiki

Mashine yetu ya kuchakata filamu za plastiki imeundwa kwa uangalifu ili kusaga tena na kuchakata aina zote za filamu kwa ufanisi. Zifuatazo ni maelezo ya kina ya laini ya granulation ya filamu ya PP PE ili kukusaidia kuelewa kikamilifu utendakazi na manufaa yake:

| Malighafi | Mifuko ya PP ya kusuka, mifuko ya saruji, filamu za kilimo na chafu, filamu za ufungaji za viwandani, filamu za kupunguza joto, filamu za kunyoosha, mifuko ya takataka, PP raffia, na filamu za Bubble |

| Bidhaa za mwisho | Chembechembe za plastiki zilizosindika |

| Aina za plastiki zinazotumika | PP, LDPE, HDPE, LLDPE, PVC, PS, nk |

| Uwezo wa uzalishaji | 100-500kg / h |

| Jinsi ya kufunga | Usaidizi wa ufungaji mtandaoni au kwenye tovuti |

| Tarehe ya utoaji | Siku 20-25 |

| Kipindi cha udhamini | 1 mwaka |

| Vifaa vya hiari | Silo ya rununu, dryer ya usawa, conveyor ya ukanda na mtoaji wa chuma, kifaa cha kupokanzwa, grinder ya kisu, nk. |

Kesi za Mauzo ya Mashine ya Kuchakata Filamu za Plastiki

Ufungaji wa Mashine ya Kuchakata Filamu ya HDPE Nchini Nigeria

With the assistance of our engineers, the HDPE film recycling machine was successfully installed and operated in Nigeria.

1000kg/H PP PE Filamu Granulation Line Katika Operesheni Nchini Saudi Arabia

We have successfully installed and operated a 1000kg/H PP PE film granulation line at our customer’s plastics recycling plant in Saudi Arabia.

Bei ya Mashine ya Kusafisha Plastiki

Mashine ya Shuliy ni mtengenezaji wa mashine ya kuchakata plastiki inayotegemewa, iliyojitolea kuwapa wateja suluhisho bora ili kuhakikisha utendaji thabiti na wa kuaminika wa vifaa.

Ikiwa una maswali yoyote kuhusu bei, utendakazi wa mashine yetu ya kuchakata mitambo ya plastiki au vipengele vingine vyovyote, tafadhali jisikie huru kuwasiliana nasi. Timu yetu ya wataalamu itafurahi kukupa maelezo ya kina na kujibu wasiwasi wako.