At present, the recycled plastic pelletizing factory has become one of the key links in the recycling of plastics. However, the establishment of a recycled plastics pelletizing plant needs to have a series of necessary conditions. Next, let’s discuss what conditions are needed.

Market Research And Demand Analysis

Before starting a recycled plastic pelletizing factory, in-depth market research and demand analysis are crucial. Understanding the trend of market demand for recycled plastics, clarifying the target customer groups, and analyzing the product characteristics of competitors are the basis for deciding the direction of development of the factory.

Regulatory Compliance And Environmental Requirements

The production of recycled plastics must comply with strict regulations and environmental requirements. When registering a manufacturer, you need to fully understand and comply with the relevant regulations to ensure that the production process does not have a negative impact on the environment. At the same time, investing in advanced environmental protection equipment – plastic recycling machines – and conducting regular environmental inspections are guarantees to ensure that the manufacturer continues to operate in compliance.

Selection And Investment Of Production Equipment

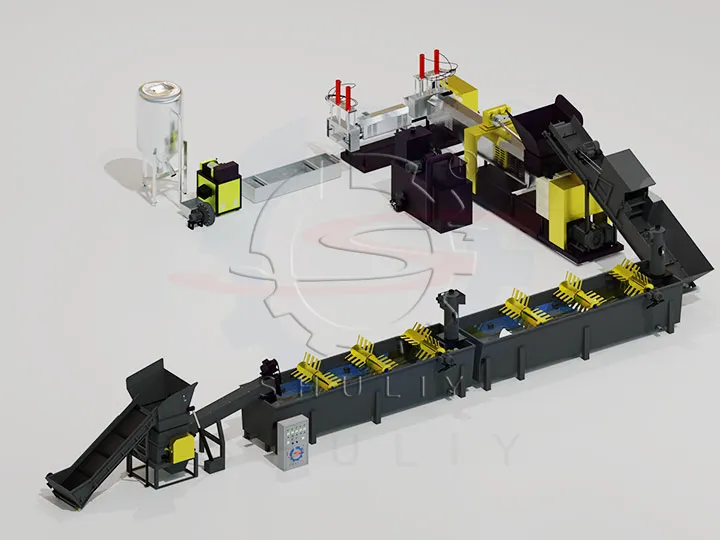

Invest in advanced plastic granulating equipment to ensure that the production process is efficient and environmentally friendly. Select appropriate plastic granulation equipment, such as waste plastic shredder machines, extrusion pelletizing machines, etc., and configure corresponding automatic control systems to improve production efficiency and product quality.

When choosing plastic granulating equipment, you need to consider factors such as production scale, types of raw materials, product types, etc., to ensure that the performance and capacity of the equipment meet the actual needs of the manufacturer. In addition, regular equipment maintenance and updating to ensure the smooth operation of the production process.

Scientific And Reasonable Production Process

Establishing a scientific and reasonable production process is the key to ensuring the efficient operation of a recycled plastic pelletizing factory. From the receipt and processing of raw materials to the packaging of the final product, each step needs to be carefully designed to maximize production efficiency and reduce production costs. A reasonable production process can not only enhance production capacity but also ensure the stability of product quality.

Starting Your Plastic Pelletizing Factory

Among the many conditions for starting a recycled plastic pelletizing factory, the selection of plastic granulation equipment and scientific and reasonable production process is particularly important. In this key area, Shuliy Machinery stands out with its advanced technology and excellent performance.

Shuliy Machinery is committed to developing and manufacturing highly efficient and environmentally friendly plastic granulating equipment. Its leading extrusion pelletizing machines and other equipment use advanced processes and materials to ensure the production of high-quality recycled plastic pellets.

Shuliy Machinery pays attention to science and rationality in the design of the plastic pelletizing production process. From raw material treatment, and extrusion pelleting to pellet forming, Shuliy Machinery provides users with a complete set of scientific and reasonable production solutions to ensure the quality and production efficiency of recycled plastic pellets.

If you want to start a plastic pelletizing factory, Shuliy Machinery can provide you with the strongest support.