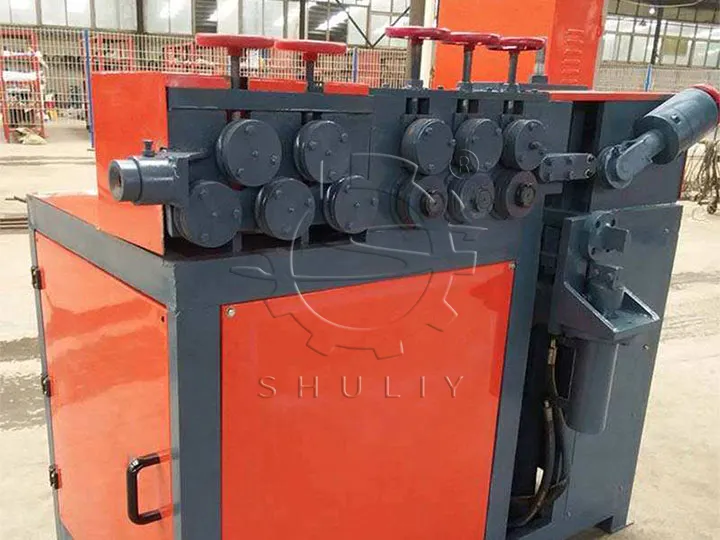

Our rebar spiral bending machine is designed for continuous processing of steel bars, integrating feeding, straightening, bending (spiral forming), and cutting into one automated workflow. The machine uses a PLC control system to ensure ±0.2 mm precision and offers multiple models suitable for steel bar diameters from 3 mm to 25 mm.

What Is a Steel Ring Making Machine?

A rebar spiral bending machine is used to produce circular rings, spiral bars, and coil-shaped steel components for applications such as high-speed railway bridges, subway projects, photovoltaic foundations, and ground anchor piles.

The machine supports full automation, batch processing, and high-speed forming, making it suitable for both construction sites and steel processing factories.

Key Features of the Rebar Spiral Bending Machine

- Integrated Feeding–Straightening–Bending–Cutting: The steel ring making machine combines all processing steps, reducing manual labor and improving production efficiency.

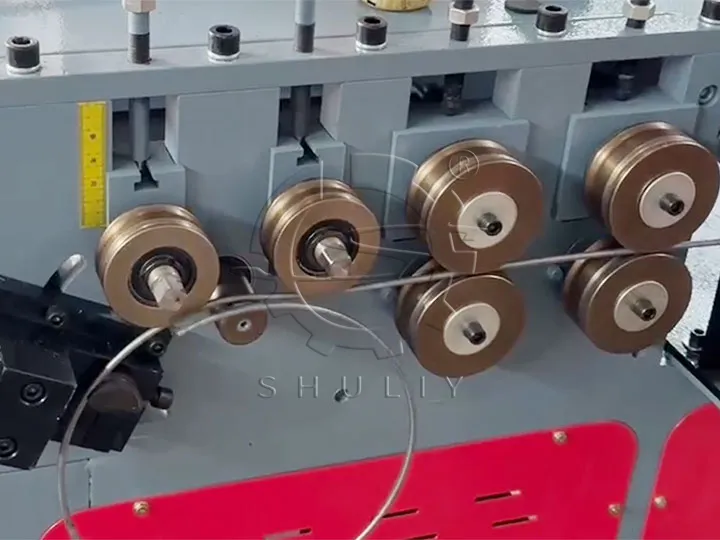

- High-Precision PLC Control System: The PLC system controls each movement with ±0.2 mm accuracy, ensuring consistent forming quality.

- Wide Processing Range: 3–25 mm: Multiple models allow customers to choose the right machine for different rebar diameters and production requirements.

- Suitable for Continuous and Batch Production: The machine can automatically process a bundle of steel bars, supporting continuous operation.

Working Principle of the Steel Bar Ring Making Machine

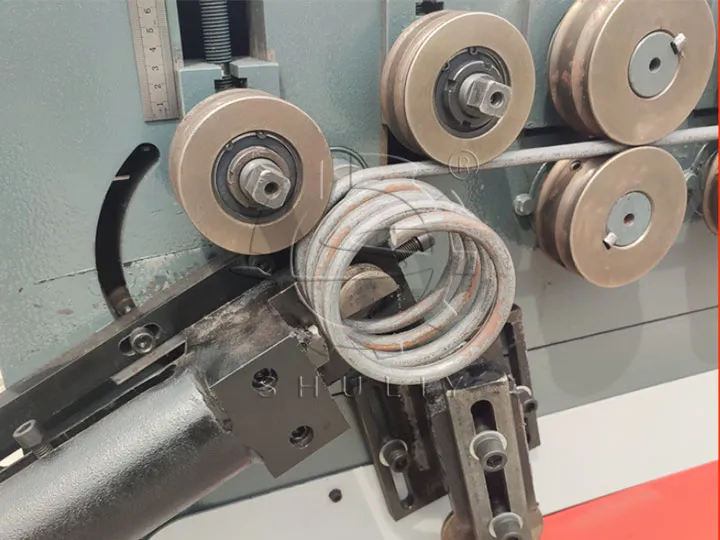

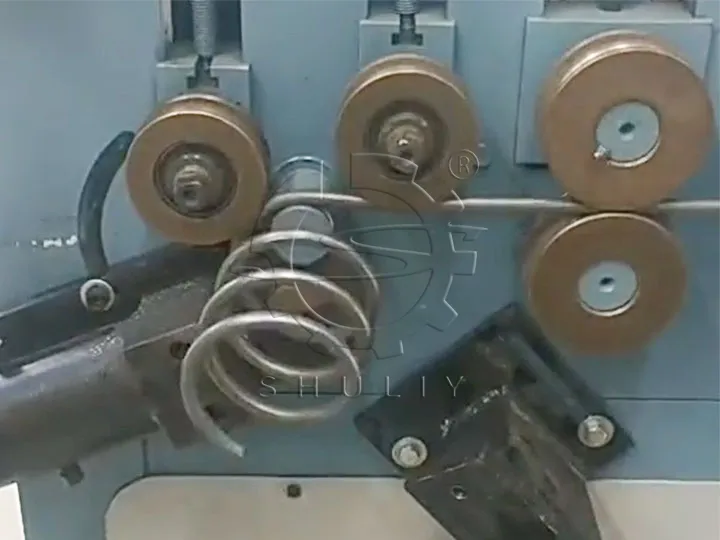

The PLC system starts the motor to drive the hydraulic pump, activating the hydraulic components that power the straightening gearbox. The steel bar is fed forward, passes through the straightening unit, and then enters the rounding assembly where the spiral or circular shape is formed.

After bending is complete, the cutting unit operates upward to cut the steel bar, finishing the entire processing cycle.

Model Specifications of the Rebar Spiral Bending Machine

| Model | Steel Bar Diameter | Ring Diameter | Total Power | Speed | Error | Size | Weight |

| 3–6 | 3–6 mm | 50–1000 mm | 4 kW | 16–25 m/min | ±0.2 mm | 1.45×0.8×1.2 m | 480 kg |

| 6–10 | 6–10 mm | 50–800 mm | 5.5 kW | 16–25 m/min | ±0.2 mm | 1.55×0.8×1.3 m | 560 kg |

| 8–12 | 8–12 mm | 50–1500 mm | 7 kW | 16–25 m/min | ±0.2 mm | 1.55×0.8×1.3 m | 640 kg |

| 10–14 | 10–14 mm | 50–1800 mm | 7 kW | 16–25 m/min | ±0.2 mm | 1.6×0.8×1.35 m | 690 kg |

| 16–20 | 16–20 mm | 50–2200 mm | 11 kW | 16–30 m/min | ±0.2 mm | 2.1×0.9×1.5 m | 1150 kg |

| 22–25 | 22–25 mm | 50–3000 mm | 15 kW | 16–30 m/min | ±0.2 mm | 2.3×0.9×1.7 m | 1350 kg |

Applications of the Rebar Spiral Bending Machine

- High-speed railway spiral bars

- Subway reinforcement rings

- Photovoltaic foundation anchors

- Construction stirrups and circular supports

- Steel processing and metal fabrication factories

Related Equipment for Rebar Processing

To support complete steel bar processing workflows, we also offer equipment such as the rebar straightening machine, rebar stirrup bending machine, and CNC pipe bending machine. Whatever your requirements for processing steel reinforcement bars, we recommend the most suitable equipment for you.

Request a Quote for the Steel Ring Making Machine

If you need a reliable rebar spiral bending machine for construction or steel processing, feel free to contact us. We provide model selection support, factory testing, spare parts supply, and overseas technical assistance.