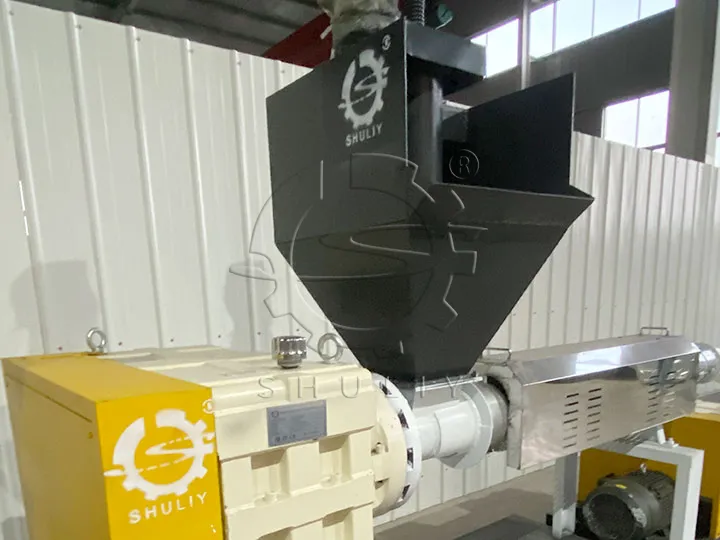

The Plastics granulator plays an important role as key equipment in the plastic recycling industry. However, in order to ensure its normal and efficient operation, proper pre-start-up preparation is crucial. The following will introduce the preparations that should be taken care of before starting the machine.

Equipment Inspection

Before starting the waste plastic extruder, it is vital to carry out a thorough inspection of the equipment. This includes checking the power wiring, the firmness of the connections to the machine components, and the normal working condition of each part.

Clean Plastics Granulator

Ensure that the interior of the plastics granulator is clean and tidy, and remove the materials left over from the previous production process. Pay special attention to cleaning the barrel and mold head so as not to affect the quality of granules in the subsequent production process.

Check Lubrication

Check the lubrication system of the waste plastic extruder to ensure that the lubricant is sufficient and the lubrication system is working properly. This can effectively reduce the wear and tear of the equipment and guarantee the stability and continuity of the production process.

Temperature Regulation

According to the characteristics of the plastic raw material, the temperature of the heating system is reasonably adjusted to ensure that the plastic can reach a suitable melting state in the extrusion process. Temperature adjustment is a key step to ensure the smooth running of the production process.

Raw Material Preparation

Prepare the plastic raw materials to be processed in advance and ensure that the quality of the raw materials meets the requirements. Avoid using expired or poor-quality raw materials, which may affect the quality and performance of the final product.

By carefully doing the preparation work before starting the plastics granulator, you can guarantee the smooth running of the production process and maximize production efficiency and product quality. This will also help to extend the service life of the equipment and reduce maintenance costs.