The plastic recycling pellet machine is one of the common equipment in the plastic processing industry, which is used to process waste plastic or plastic granules into granular raw materials. Its structural composition directly affects its production efficiency and processing quality. In this paper, we will discuss the main components of extruder machine plastic and their functions.

Plastic Recycling Pellet Machine Structure

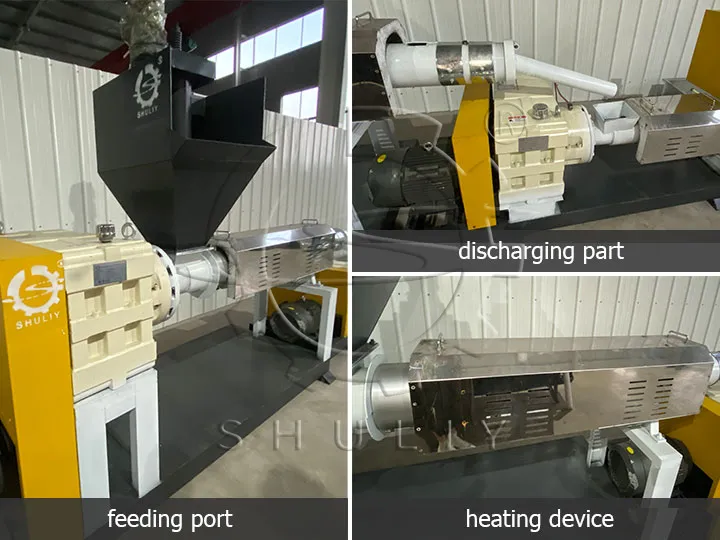

Feed Inlet

The feed inlet of the granulating machine plastic recycling is the starting position for raw material input. Waste plastic or plastic granules are fed into the machine through the feed opening as the starting point for processing.

Automatic Feeding Device

The automatic feeding device is an important part of the extruder machine plastic, used to control the input quantity and speed of raw materials. It enables precise control of material quantity, improves production efficiency, and ensures stability and consistency of the process.

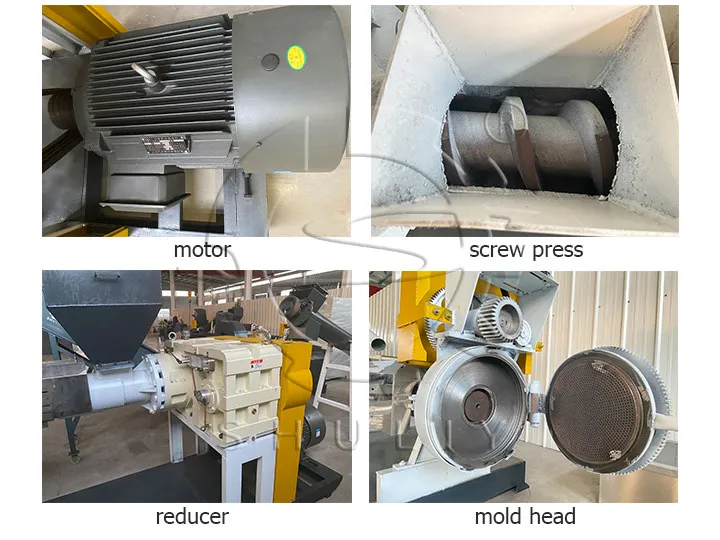

Speed Reducer

A reducer is one of the key equipment in the granulating machine plastic recycling, which is mainly used to regulate the rotational speed of the screw and control the movement speed of raw materials inside the machine. Through the role of the speed reducer, the processing can be better controlled to ensure the uniformity and quality of the granules.

Heating Unit

The heating device is usually located around the screw of the plastic recycling pellet machine, used to heat the raw material and improve its fluidity. Through the action of the heating device, the viscosity of the raw material can be reduced, the energy consumption during processing can be reduced, and the molding effect of the granules can be improved.

screw

The screw is one of the core components of a plastic recycling pellet machine, its main role is to transport the raw material from the inlet to the die head and complete the steps of melting, compression, and extrusion in the process. The design and structure of the screw directly affect the molding effect and processing efficiency of the granules.

Electric Motor

As the power source of the plastic recycling pellet machine, the motor is responsible for driving the screw and other moving parts. The selection of its power and speed should be reasonably matched according to the characteristics of the processed raw materials and production requirements to ensure that the machine can run stably and achieve the expected processing results.

Die Head

The die head is the outlet of the extruder machine plastic, through the design and adjustment of the die head, the control of parameters such as shape, size, and density of the granules can be achieved. High-quality die heads can ensure the uniformity and consistency of granules, which improves the quality and market competitiveness of products.

Conclusion

The structural composition of the plastic recycling pellet machine includes several parts such as a feed inlet, automatic feeding device, reducer, heating device, screw, motor, mold head, etc., and each part plays an important role. Through reasonable design and optimal assembly, the processing efficiency of the granulating machine plastic recycling can be improved, energy costs can be saved and high-quality plastic granules can be produced.