The plastic pellet extruder machine is a kind of equipment used to process plastic waste or raw materials into granules, and its temperature control is one of the important factors affecting the quality of plastic granules. Correctly adjusting the temperature can ensure the quality of pellet molding and production efficiency. The following will describe how to adjust the temperature of the plastic recycling extruder to get the best results.

Plastic Pellet Extruder Machine Temperature Adjustment

Understanding The Melting Temperature Of Plastics

Different types of plastics have different melt temperatures and it is vital to know the melt temperature of the plastic you are working with. Generally, the melt temperature of a plastic can be found in the relevant technical documentation or production guide. Once you have determined the melt temperature, you can set the temperature of your plastic pellet extruder machine as required.

Control Of Feed Zone Temperature

The first step of the plastic granules entering the plastic pellet extruder machine is to enter the feed zone. In this zone, the plastic pellets begin to be heated and gradually melt. Ensure that the temperature in the feed zone is appropriate for the melting temperature of the plastic, usually set at one-half to two-thirds of the melting temperature of the plastic. By adjusting the heating temperature in the feed zone, the rate at which the plastic pellets are melted can be controlled to avoid production problems caused by going too fast or too slow.

Adjustment Of Extrusion Zone Temperature

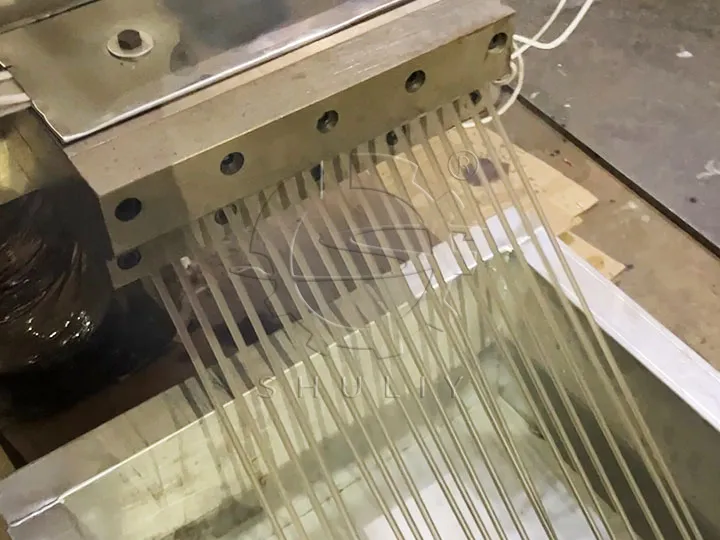

The extrusion zone is the area of the plastic pellet in a plastic pellet extruder machine where the plastic pellets are melted and extruded. In this zone, the plastic pellets are further melted and mixed under the pressure and heat of the extrusion screw. Adjusting the temperature in the extrusion zone can affect the flow of the plastic pellets and the extrusion results. Typically, the temperature in the extrusion zone should be slightly higher than the melting temperature of the plastic to ensure that the plastic can be extruded smoothly and that the shape and size of the pellets can be controlled by appropriate adjustments.

Controlling The Temperature In The Mold Area

In the mold area, plastic pellets are pressed into the desired shape. Temperature control in the mold area is critical to the quality of the pellets being formed. Typically, the temperature in the mold area should be set according to the specific plastic material and pellet shape. Setting the temperature too high may cause the pellets to overheat, distort, or stick together, while setting it too low may result in incomplete or defective pellet molding. Therefore, it needs to be adjusted according to the actual situation to obtain the best molding results.

Conclusion

By correctly regulating the temperature of your plastic pellet extruder machine, you can ensure the quality and productivity of your pellets. Understanding the melting temperature of the plastic and controlling the temperatures in the feed zone, extrusion zone, and mold zone is key to achieving good pelletizing results. Therefore, when operating a waste plastic granulator machine, it is important to adjust the temperature according to the specific situation to meet production requirements and ensure pellet quality.