The plastic baler machine is a professional equipment designed for efficient compression and packaging of various waste plastics or other materials. The equipment is designed to facilitate the transport and storage of a wide range of waste materials, including waste cardboard boxes, PET bottles, oil drums, woven bags, and more. With the hydraulic plastic baling machine, these raw materials can be efficiently compressed into sturdy packages, thus improving transport efficiency and storage space utilization.

Raw Materials Of Plastic Baler Machine

The plastic baler machine is mainly applied to efficiently compress and pack all kinds of waste plastics or other materials, widely applicable raw materials include waste cartons, PET bottles, oil drums, woven bags, cardboard boxes, plastic film, old clothes, textiles, wool, cotton, straw and so on.

Advantages of Hydraulic Baling Press

- Versatile Material Handling: Capable of baling various waste materials such as plastic bottles, woven bags, aluminum cans, and more.

- Customizable Options: Can be customized to meet specific customer requirements, including voltage, appearance, bale size, and other specifications for different applications.

- Diverse Models: Offers a variety of models to meet different production capacity needs, ensuring efficient operation.

- Efficient Space Saving: Compresses and bales waste, significantly reducing storage space and optimizing logistics and storage costs.

- Reliable and Durable: Built with high-quality materials and advanced technology to ensure long-term, stable performance.

Baler Machine Application Places

Hydraulic baling press machines find applications in various settings, including:

- Recycling Facilities: For efficient processing of large volumes of collected plastic bottles.

- Bottling Plants: To manage post-consumer bottle waste generated during production.

- Waste Management Companies: For optimizing collection, transportation, and recycling operations.

- Retail Stores and Supermarkets: To handle plastic bottle waste generated by customers.

Working Principle Of Plastic Baling Machine

Material placement: Put the waste plastic materials to be processed (e.g. plastic film, bottles, bags, etc.) into the inlet or compression chamber of the baler machine.

Compression process: After starting the plastic recycling baler machine, the hydraulic or mechanical system drives the platen downwards, exerting enormous pressure on the plastic material and compressing it into a tight block.

Forming and strapping: After compression molding, the plastic baling machine will use special strapping bands or steel wires to tie and fix the compressed plastic blocks to prevent them from falling apart during handling and storage.

Discharge: When the baling is complete, the machine’s platen will lift to release the compressed plastic block and push it out of the plastic baler machine. At this point, the baled plastic blocks can be handled, stored, or transported.

Classification Of Hydraulic Plastic Baling Machine

Vertical Baler

Vertical balers have a vertical design and work by placing material into a compression chamber and then using hydraulics to compress the material into a strong parcel. Such parcels can be square, rectangular, or other shapes, depending on the design and setup of the machine. Due to their vertical design, these balers typically require a smaller footprint and are suitable for working environments where space is limited.

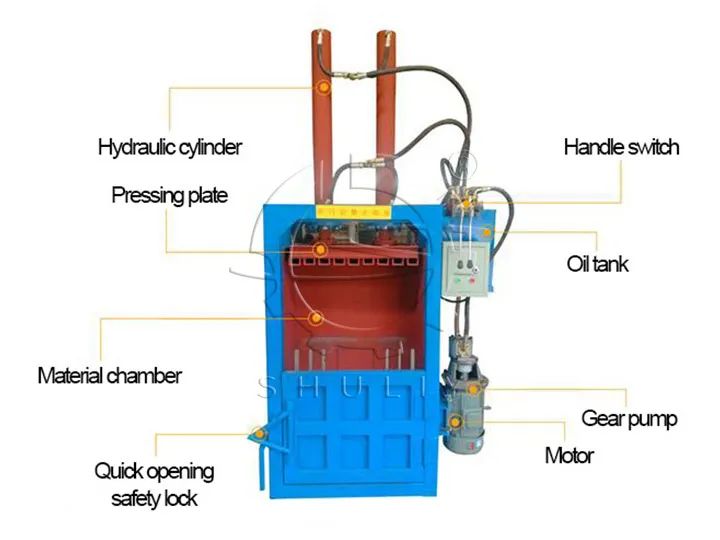

Vertical Baler Structure Diagram

Parameter Sheet

| Model | Pressure(T) | Power(KW) | Capacity(h) |

| SL-30T | 30 | 5.5 | 0.8-1T |

| SL-80T | 80 | 11 | 2-3T |

| SL-120T | 120 | 18.5 | 4-5T |

Working Video of Vertical Baler

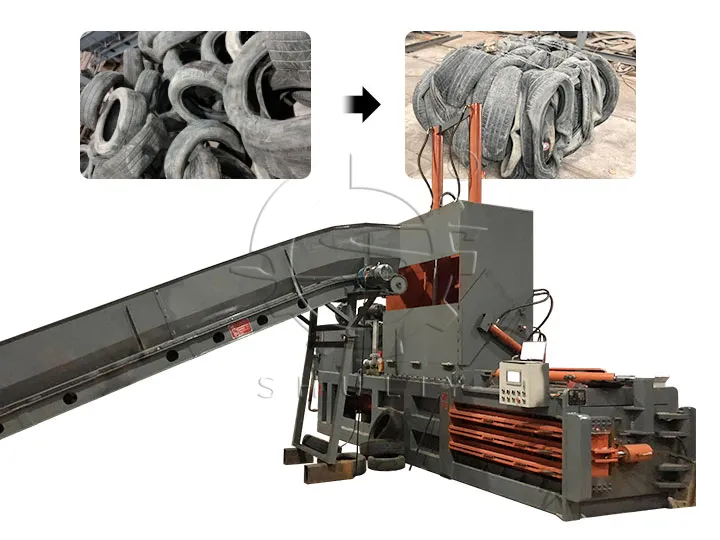

Horizontal Plastic Baler

Horizontal plastic balers are designed horizontally, larger, and more automated than vertical balers and are suitable for handling large quantities of PET bottles or hay, tires, cardboard, etc.

Parameter Sheet

| Model | Power(kW) | Baling size(mm) | Capacity(t/h) |

| SL-120 | 22+18.5 | 1100*900*1200 | 5-8 |

| SL-160 | 22+18.5 | 1100*1300*1500 | 7-10 |

| SL-200 | 37+22 | 1100*1300*1700 | 10-15 |

Working Video of Horizontal Baler

Related Machines-Plastic Unwrapping Machine

Shuliy Machinery offers vertical balers and horizontal balers to meet the different needs of customers. Besides, we also provide plastic unwrapping machines, which are used to break up and unpack the bundled materials to improve the production efficiency of PET plastic recycling lines or waste plastic granulation lines.

Plastic Baler Machine Export Case

Recently, a customer from Tanzania ordered 5 balers from us for waste management. The baler’s bale size is 600*1120mm. It can pack 2 to 3 bales per hour, and the weight of each bale is 100kg.

Our hydraulic balers are not only suitable for baling plastics but also for baling waste paper, cans, old clothes, and other kinds of waste materials. No matter you have any baling needs, welcome to contact us at any time.