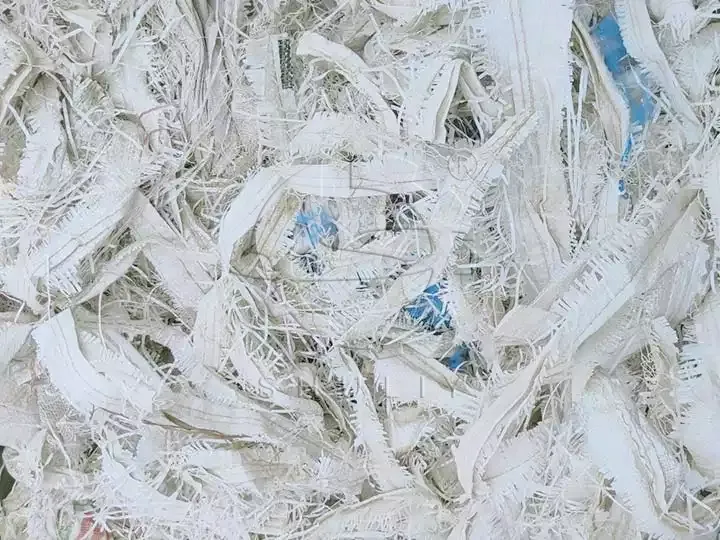

As a key equipment in the processing of plastic materials, the performance and efficiency of waste plastic extruders are significantly influenced by the choice of plastic raw materials. This article delves into the impact of different types of plastic raw materials, such as polyethylene, polypropylene, etc., on waste plastic extruders. It explores the characteristics of the materials, factors considered in their selection, and the ultimate applications of the prepared pellets.

Categories Of Plastic Raw Materials

Plastic raw materials are diverse, including but not limited to polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and more. Each type of material possesses unique physical and chemical properties, requiring consideration of specific application needs during the selection process.

Consideration Factors Of Material Characteristics

Melt Index (MI): Influences the flowability of plastics during the extrusion process. A higher melt index often indicates better flowability, contributing to the production of more uniform pellets.

Hardness and Toughness: Different applications have varying requirements for the hardness and toughness of pellets. For instance, some applications demand pellets with higher hardness, while others may require pellets with greater toughness.

Chemical Stability: Consider the resistance of plastic pellets to chemical corrosion in specific environments to ensure the stability and durability of the final product.

Selection Consideration Factors

- Cost: The cost difference among different plastic raw materials is substantial. Therefore, it is essential to consider production costs and the market competitiveness of the final product during the selection process.

- Recyclability: With the increasing importance of sustainability, choosing recyclable plastic raw materials is crucial to reduce environmental impact.

- Production Efficiency: Different plastic raw materials also impact the production efficiency of waste plastic extruders. Some materials may be more easily extruded and pelletized, thereby improving production efficiency.

Applications Of The Final Pellets

Based on the chosen raw materials and the characteristics of the waste plastic extruder, the final pellets can be utilized in various applications, including but not limited to plastic product manufacturing, packaging, construction materials, etc. Different applications have diverse requirements for pellets, emphasizing the critical importance of selecting suitable materials and plastic recycling granulators.

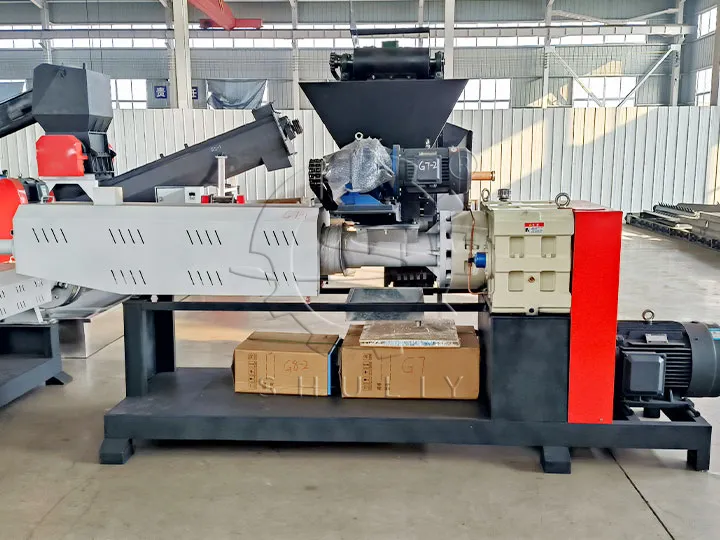

Help You Choose Waste Plastic Extruder

In the process of plastic pellet production, the correct selection of plastic raw materials is a key factor in ensuring the quality of the final product and production efficiency. By carefully considering the characteristics of the materials, selection factors, and the intended applications of the final pellets, the performance of waste plastic extruders can be maximized to meet the diverse needs of different industries.

In plastic pellet production, choosing the right plastic recycling granulator is crucial. With its advanced technology and extensive experience, Shuliy Machinery is able to customize the most appropriate waste plastic extruder for your type and quantity of raw material. We have an in-depth understanding of the characteristics of your raw materials and consider a variety of factors to ensure that the final pellets are optimized in terms of quality and productivity. By working closely with you, we are committed to maximizing the performance of our plastic recycling granulator to meet the unique needs of different industries and to provide reliable support for your production.