Regular maintenance of the granulator machine is the key to ensuring its normal operation and extending its service life. Effective maintenance measures can not only improve production efficiency but also reduce the equipment failure rate and maintenance costs. Here are some effective methods for maintaining plastic granule machines.

Regular Cleaning And Lubrication

Regular cleaning of all parts of the granulator machine is fundamental to keeping it running efficiently. Remove accumulated plastic debris, dust, and other impurities in a timely manner to ensure that the inside of the machine remains clean. At the same time, lubricate the machine regularly to minimize wear and tear and ensure smooth operation of the components.

Watch For Wear and Tear On Parts

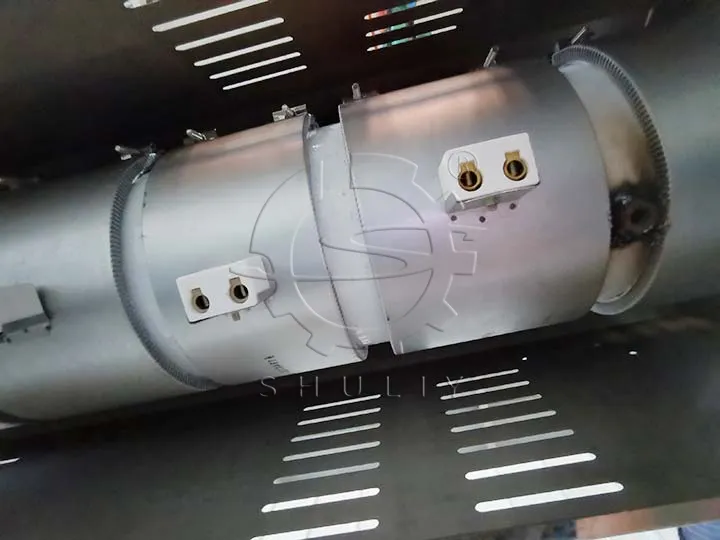

Regularly check the key parts of the plastic pelletizer recycling machine, especially the mold head, heating device, and transmission system. Replace them in time when they are found to be worn or damaged, so as to avoid the normal work of the equipment being affected by the wear and tear of the parts.

Rational Use And Load Control

Reasonable use of the granulator machine is the key to protecting its long-term operation. Avoid overloading operations and long hours of continuous work to prevent overheating of the equipment and damage to parts.

Periodic Maintenance Records

Create detailed maintenance records, including when maintenance is performed, what is maintained, and when parts are replaced. This helps to track the maintenance of the equipment and to identify and resolve potential problems in a timely manner.

Granulator Machine For Sale

Through regular cleaning, lubrication, parts inspection, and reasonable use, the plastic pelletizer recycling machine can be kept in good running condition and prolong its service life. Adherence to effective maintenance measures can not only improve production efficiency but also reduce maintenance costs.

Shuliy Machinery’s granulator machines feature advanced manufacturing technology and reliable performance. We offer a full range of after-sales services, including operating instructions and maintenance advice, to ensure that our customers are able to make full use of our equipment for efficient plastic recycling processing.