Recycled plastic pellets, processed from waste plastic products, have a wide market. Regardless of the world, wherever there are people, it is inevitable to produce waste plastics, and the price is low, it will be processed into recycled pellets, low cost, quick results, and high returns.

Plastic pellets are very popular with plastic product manufacturers and most of the plastic daily necessities on the market are made of recycled pellets. So how are plastic granules made? In this article, we will look at the raw materials required to make recycled plastic pellets, the process, and the plastic recycling machines involved.

Choosing The Right Plastic For Recycling

Before we delve into the production process, it is necessary to consider what types of plastics are suitable for recycling into recycled plastic granules. Common recyclable plastics include:

- PET (polyethylene terephthalate): commonly used in water and beverage bottles.

- HDPE (High-Density Polyethylene): Used in products such as milk bottles and detergent containers.

- PP (Polypropylene): Used for various packaging materials and automotive parts.

- LDPE (Low-Density Polyethylene): Used in products such as plastic bags and films.

- PS (polystyrene): used for disposable tableware and packaging materials.

Recycled Plastic Pellets Production Process

Recycling plastics into pellets involves several steps. Let us describe the process in detail:

Collection and classification

Plastic waste is first collected and sorted, screening it according to type and quality. This step is crucial to ensure that only suitable materials are processed into pellets.

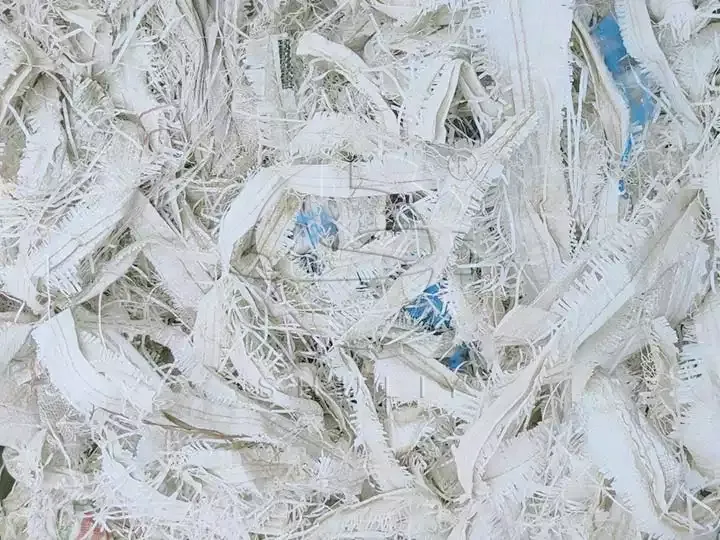

Crushing

The first step in a plastic recycling granulating line is to crush waste plastics into pieces, a process that is intended to be followed by easy washing and pelletizing.

Washing And Drying

The crushed plastic chips are washed to remove impurities such as dust, oil, and other contaminants. The washing process ensures that the recycled plastic pellets are of high quality. The washed plastic requires a plastic dryer to remove excess water.

Extrusion And Pelletizing

The cleaned plastic enters the plastic recycling pellet machine, where it is heated and melted to extrude long strips of plastic, which are cooled and cured and then cut into recycled plastic pellets.

Recommended Equipment For Plastic Granulation

A range of plastic recycling machines is essential for customers who want to get into the plastic recycling business. As a manufacturer and exporter of plastic recycling machines for many years, Shuliy Factory recommends several useful machines to you.

- Plastic shredder for recycling: The machine is used to shred plastic waste into the required size for easy disposal.

- Plastic chips washing machine: Washing equipment is used to wash and remove impurities from plastics.

- Drying machine for plastic: This plastic recycling machine is used to remove water from plastics to ensure their stability during the plastic pellet production process.

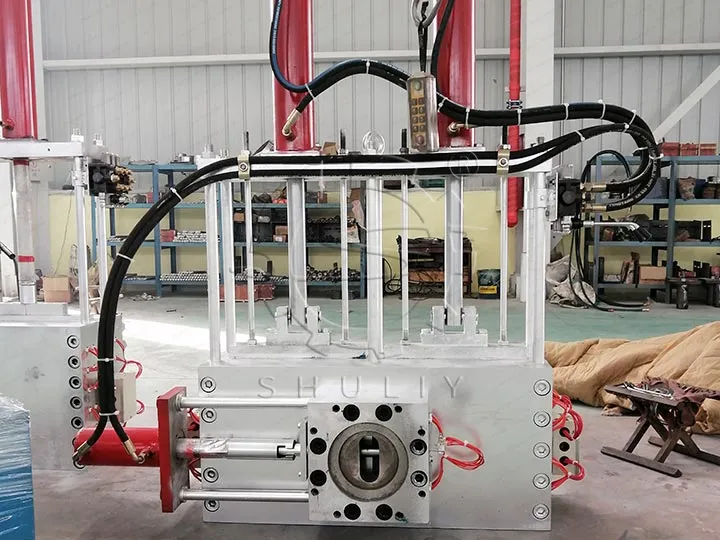

- Plastic recycling pellet machine: This machine is the key machine for making recycled plastic pellets, and melting and extruding the plastic.