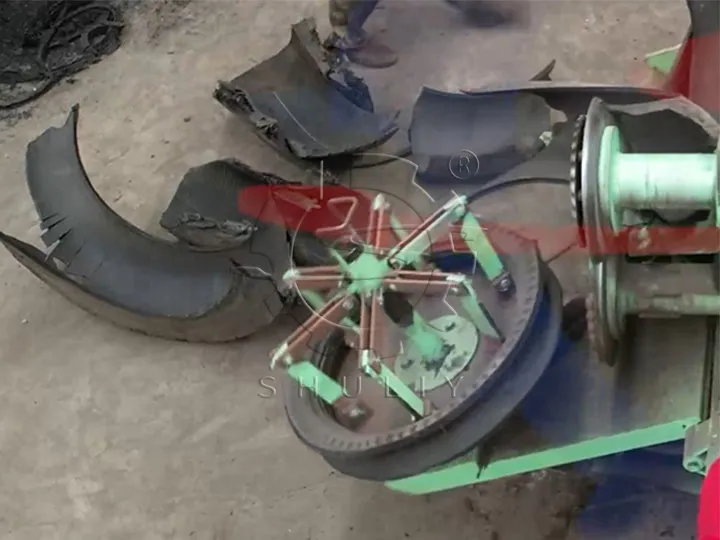

La machine de retrait de talon et de coupe de pneus est un équipement spécialisé conçu pour traiter efficacement les pneus de voitures particulières, les pneus de camions légers et similaires d'un diamètre allant jusqu'à 1200 mm. Cette machine avancée est capable de retirer les talons en fil d'acier des flancs tout en coupant simultanément le pneu, ce qui en fait une étape de prétraitement idéale avant d'alimenter un déchiqueteur de pneus.

En intégrant deux opérations en une, elle réduit les coûts de main-d'œuvre, accélère le traitement et assure des résultats de coupe constants, ce qui en fait l'une des machines de coupe de flancs de pneus de camion les plus avancées disponibles aujourd'hui.

Pneus Applicables et Résultats de Traitement

Cette machine de retrait de talon et de coupe de pneus convient aux pneus de voitures particulières, aux pneus de camions légers et à certains pneus hors route légers, tant que le diamètre ne dépasse pas 1200 mm. Pendant le traitement, elle retire avec précision les fils d'acier des deux côtés et coupe le pneu en sections gérables. Les surfaces de coupe sont nettes et les fils de talon sont complètement retirés, ce qui garantit des conditions optimales pour les étapes ultérieures de déchiquetage et de broyage.

Caractéristiques clés et avantages

Double Fonction – Retrait du Talon et Coupe en une Seule Étape

Contrairement aux configurations traditionnelles où le retrait du talon et la coupe sont effectués séparément, cette machine de démontage de pneus combine les deux processus, améliorant l'efficacité et réduisant le temps de manipulation.

Convient aux Pneus jusqu'à 1200 mm de Diamètre

La machine de retrait de talon et de coupe de pneus peut traiter la plupart des pneus de voitures particulières et de camions standard avec un diamètre maximum de 1200 mm, ce qui la rend polyvalente pour divers projets de recyclage.

Prépare les Pneus au Déchiquetage

Une fois traités, les pneus sont coupés et débarrassés de leurs fils d'acier, ce qui les rend plus faciles et plus sûrs à introduire dans les déchiqueteuses de pneus, réduisant ainsi l'usure des équipements en aval.

Construction Robuste et Fiable

Fabriquée avec des matériaux robustes et des lames de coupe avancées, la machine garantit une longue durée de vie et des performances stables en fonctionnement continu.

Intégration dans les Lignes de Recyclage de Pneus

La machine de retrait de talon et de coupe de pneus peut être facilement intégrée dans diverses lignes de recyclage de pneus usagés. Elle fonctionne parfaitement avec les séparateurs de fils d'acier, les déchiqueteuses de pneus et les machines de broyage de poudre de caoutchouc pour former une ligne de production de poudre de caoutchouc complète.

Grâce à une combinaison d'équipements appropriée, les pneus usagés peuvent être transformés en poudre de caoutchouc de haute pureté avec un minimum d'effort manuel, garantissant une efficacité de production plus élevée et une qualité de produit constante.

Applications de la Machine de Retrait de Talon et de Coupe de Pneu

La Machine de Retrait de Talon et de Coupe de Pneu est idéale pour :

- Les usines de recyclage de pneus traitant les pneus de voitures particulières et de camions légers

- Le prétraitement des pneus pour le déchiquetage et le broyage en poudre ou granulés de caoutchouc

- Les opérations nécessitant une réduction des étapes de main-d'œuvre et une amélioration de la sécurité lors du traitement des pneus

Paramètres de la Machine de Retrait de Flanc et de Coupe de Pneu

- Puissance : 7,5 + 3 kW

- Dimensions : 2,45 x 1 x 1,7 m

- Dimensions de la caisse en bois : 2,6 x 1,2 x 1,9 m

- Poids : 1500 kg

- Taille des pneus traités : 900–1200 mm

- Rendement : 3 tonnes/h

- Matériau de la lame : Chrome 12 Molybdène Vanadium

Contactez-nous pour le Prix de la Machine de Recyclage de Pneus

La machine de démontage de pneus est un appareil de prétraitement essentiel dans le processus de recyclage des pneus. Elle combine les fonctions de retrait du talon et de coupe du pneu, ce qui entraîne une efficacité accrue et une opération plus pratique, et assure une meilleure préparation des matières premières pour le traitement ultérieur.

Que vous mettiez à niveau une usine de recyclage existante ou que vous construisiez une nouvelle ligne de production, cette machine de retrait de talon et de coupe de pneus peut augmenter efficacement votre capacité et réduire vos coûts d'exploitation.

N'hésitez pas à nous contacter pour en savoir plus sur nos solutions de recyclage de pneus, obtenir un plan de configuration d'équipement personnalisé et recevoir des prix spécifiques adaptés à vos besoins.