The EPE foam granule machine is suitable for EPE pearl cotton foam waste material, which can be processed into granules. This machine has fast feeding speed, stable heating temperature, simple and reasonable design and operation, and high production efficiency. The quality of recycled granules is guaranteed.

What Is An EPE Granulator?

The EPE granulator is a machine specially designed to process EPE foam material, aiming to convert waste EPE material into useful recycled pellets. This EPE foam granule machine is suitable for a wide range of EPE foam materials including EPE foam boards, EPE foam rolls, EPE foam blocks, etc., with a wide range of applications.

Raw Materials of EPE Foam Granule Machine

EPE styrofoam pelletizing machine is used to process all kinds of waste foam, pearl cotton recycling, and granulation, such as cushioning, protection, packaging materials, thermal insulation materials, heat insulation materials, and protective pads.

EPE foam, also known as EPE pearl cotton, is a lightweight material and a new type of environmentally friendly packaging material. Due to its recyclability and renewability, EPE foam is considered a relatively environmentally friendly foam material.

Application Areas of EPE Pelletizer

- EPE foam products manufacturers: Recycle the edges and scraps produced in the production process, and reduce the cost of raw materials.

- Waste material recycling station: Process the collected EPE foam waste to improve the recycling value.

- Environmental protection enterprises: Participate in the resource utilization project of EPE foam waste to promote the development of a circular economy.

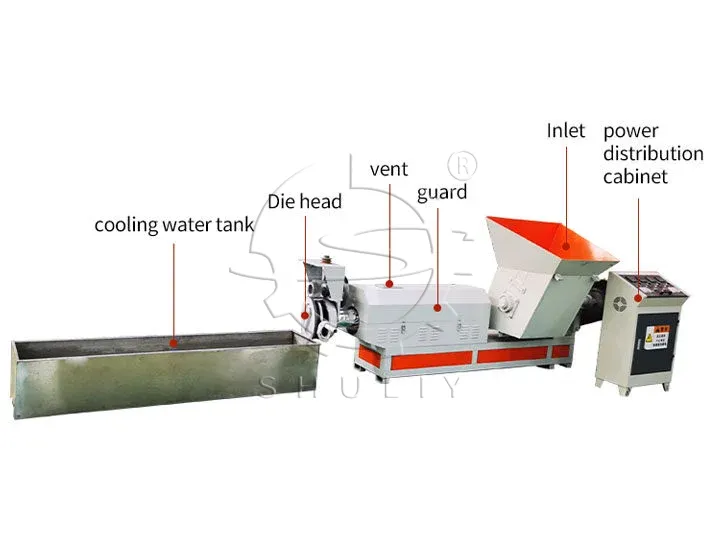

Composition of EPE Styrofoam Pelletizing Machine

EPE granulator consists of a power distribution cabinet, inlet, guard, vent, die head, cooling water tank, and so on.

Working Principle Of EPE Foam Recycling Machine

EPE foam enters from the inlet, is crushed into small pieces by the shredding device, and then enters the inside of the EPE foam recycling machine to be heated and melted, and then extrudes plastic strips from the die head. After cooling, the plastic strip enters the plastic pellet cutting machine to be cut into uniform granules.

Detailed Information on EPE Granulator

| Plastic granulator manufacturer | Shuliy Machinery |

| Product | EPE Styrofoam Pelletizing Machine |

| Model | SL-160 |

| Capacity | 150-200kg/h |

| Power | 30kw |

| Heating method | heating ring |

| Machine size | 3400*2100*1600mm |

| Raw materials | EPE foam |

| Final products | EPE pellets |

| Date of delivery | 20-25 working days |

Uses Of EPE Recycled Pellets

- Making Pearl Cotton Products: EPE pearl cotton recycled pellets can be used to make a variety of pearl cotton products, such as pearl cotton packing boxes, thermal insulation materials, gaskets, sound insulation materials, and so on.

- Making Floor Mats: EPE Pearl Cotton recycled pellets can also be used to make floor mats.

- Making Toy Stuffers

EPS Granules Making Machine Shipped to Suriname

Recently, we delivered an EPE foam granulator to our customer in Suriname, which has an output of 150-200kg/h and adopts the heating ring heating method, which can meet the customer’s daily production demand for EPE foam recycling.