Plastic pellet makers in the processing of plastic raw materials, sometimes there will be cases of broken strips when granulating, which brings some trouble to the production process. There are many reasons for this phenomenon, which we will discuss in detail below.

Plastic Recycling Extruder Workflow

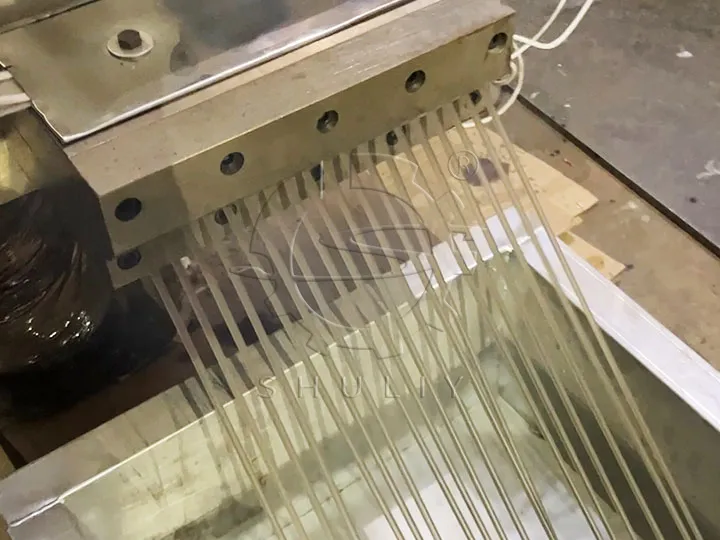

Firstly, we need to understand the workflow of the plastic pellet maker to understand why it breaks. Firstly, the raw materials enter the plastic granulator, which is then heated and melted. Then, they are extruded into the mold head through a screw, and continuous plastic strips are extruded through the mold head. This is how the machine works, next, we talk about the causes and solutions of broken bars.

Causes Of Plastic Pellet Maker Strip Breakage

- Poor quality of raw materials: The quality of plastic raw materials directly affects the effect of granulation. If the raw material contains impurities, high moisture or uneven particles, and other problems, it is easy to lead to the plastic recycling extruder in the working process of the broken bar phenomenon.

- Machine Failures: Damaged or improperly adjusted parts of the plastic recycling extruder may also result in broken bars. For example, problems such as worn molds, worn screws, and improper temperature settings may affect granulation continuity.

- Improper operation: The operator’s technical level and operating experience are crucial to the working effect of the plastic granulation equipment. Incorrect operation methods may lead to unstable working of the machine, which may result in broken bars.

How To Solve The Problem Of Broken Bars During Granulation?

- Selection of high-quality raw materials: Ensure the use of good quality, no impurities, moderate humidity of the plastic raw materials, and can effectively reduce the occurrence of broken bars.

- Regular Maintenance and Inspection: Regularly maintain the plastic pellet maker, check whether the mold, heating system, temperature control system, and other parts are normal, and replace the damaged parts in time to ensure the normal operation of the machine.

- Reasonable adjustment of parameters: According to different raw material characteristics and production requirements, set the working parameters of the plastic pellet maker reasonably, including temperature, pressure, speed, etc., to ensure a continuous and stable granulation process.

- Training of operators: Provide professional training for operators to improve their operating skills and work experience, standardize the operation process, and avoid the problem of broken bars caused by improper operation.

To sum up, the phenomenon of broken strips when granulating plastic pellet makers may be caused by a variety of reasons, but the reasonable selection of raw materials, regular machine maintenance, scientific operation methods, and other measures, can effectively solve this problem, improve the production efficiency of the plastic granulation equipment and product quality, and make greater contribution to the recycling of plastics.