In the global plastic recycling industry, extrusion pelletizing machines are highly regarded for their efficient processing capabilities and superior product quality. Recently, we welcomed a customer from Guinea who had been in detailed communication with our sales manager via WhatsApp.

After learning more about our equipment, the customer decided to visit our factory in person to gain a deeper understanding of our plastic strand pelletizer and its related technologies. Here is a detailed account of the customer’s visit.

Initial Inquiry and Decision to Visit

The customer from Guinea, involved in the plastic recycling business, was looking to invest in an extrusion pelletizing machine suitable for their production line.

During their online communication with our sales manager, the customer expressed strong interest in our equipment and wanted to learn more about our technical features, product quality, and the equipment’s performance.

After a thorough discussion, the customer decided to visit our factory for a hands-on look at our machinery and its processes.

On-Site Tour: In-Depth Understanding of the Extrusion Pelletizing Machine

Upon arrival, our sales manager personally guided the customer through our production workshop and equipment display area. We started by introducing our plastic strand pelletizer, with a focus on its heating system.

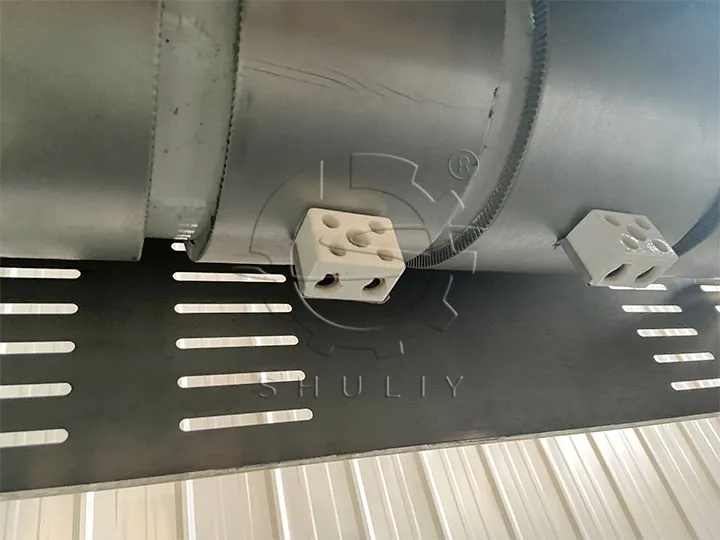

Our plastic waste extruder machine has three main heating methods, electromagnetic heating, ceramic heating, and electric heating, customers can choose according to their raw materials and needs.

For more information on heating methods check out this article: Differences In Heating Methods Of Plastic Pelletizing Extruder

Introduction to the Working Principle of Plastic Pellet Extruder

Next, we explained the working principle of the extrusion pelletizing machine in detail. The machine uses a screw extruder to process the raw material, applying high temperatures to melt the plastic and then forming pellets through the cooperation of the die head and cutting unit. This process is highly efficient for processing a variety of plastic waste, producing consistent and high-quality recycled pellets.

Introduction of Applicable Raw Materials And Supporting Equipment

During the visit, we also introduced the types of raw materials to which the extrusion pelletizing machine is applicable. The equipment is widely used in the recycling and processing of PP, PE, PVC, and many other plastics.

In addition, we also introduced to the customer the equipment supporting the plastic pellet extruder, including the material conveying system, cooling system, pellet cutting machine, etc. These supporting equipment can work perfectly with the main machine to ensure the production line can be processed. These ancillary equipment can perfectly match the main machine to ensure the smooth operation of the production line.

Visit Summary

Through this visit, the Guinea customer gained a more comprehensive understanding of our plastic strand pelletizer and its related technologies. Not only did we showcase the efficiency and stability of our equipment, but we also addressed the customer’s technical questions and helped them understand how our machinery can enhance their production efficiency and product quality.

After the visit, the customer expressed high appreciation for our equipment and technology and mentioned that they would use the detailed information gathered on-site to make further decisions. We look forward to continued cooperation with this customer and are eager to provide high-quality plastic recycling equipment and solutions to our global clientele.