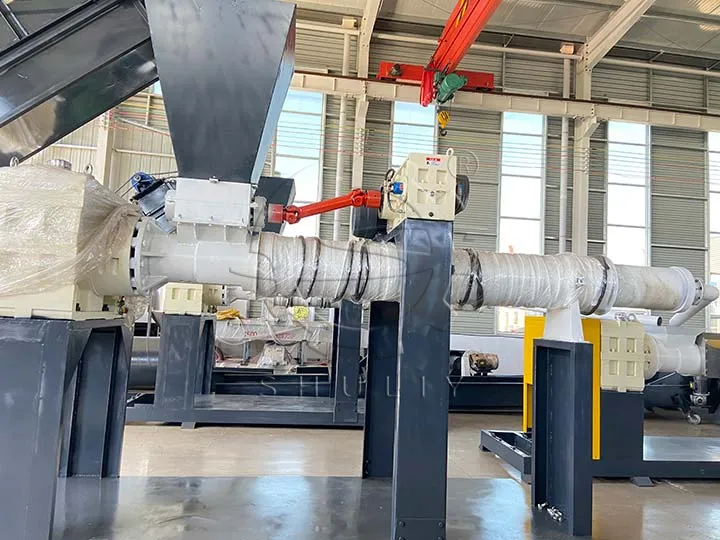

In the process of plastic pelletizing process, the heating of plastic pelletizing extruder is one of the vital links. Different heating methods directly affect the quality and production efficiency of plastic pellets. In this article, we will discuss in depth the three main heating methods of plastic recycling extruder machines: electromagnetic heating, ceramic heating, and ordinary electric heating, to help customers better understand their differences and their respective advantages.

Electromagnetic Heating

Electromagnetic heating is a way of generating a magnetic field by inducing an electric current, and then transferring the energy to the object to be heated through the magnetic field. In plastic pelletizing extruder, electromagnetic heating usually uses electromagnetic induction coils, which has the advantages of fast, efficient, and even heating. However, the equipment cost of this method is relatively high and requires professional maintenance.

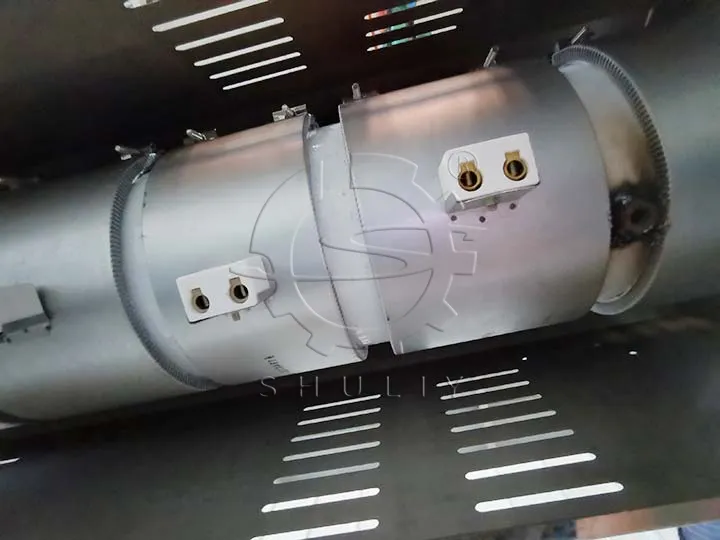

Ceramic Heating

Ceramic heating is a way to achieve heating by transferring energy to the plastic through ceramic heating elements. This method is characterized by low thermal inertia and fast response speed, which helps to improve production efficiency. In addition, the equipment of ceramic heating is relatively more stable and can work at higher temperatures, which is suitable for some special plastic materials.

General Electric Heating

Ordinary electric heating is a more traditional heating method, through the resistance heating wire generated by the heat transfer to the plastic. This method is relatively low-cost and simple to maintain and is suitable for some production scenarios with low to medium temperature requirements. However, the disadvantage of ordinary electric heating is that the heating is not uniform enough, which may cause the quality of plastic granules to be unstable.

Three Heating Methods For Plastic Pelletizing Extruder

When choosing a plastic pelletizing extruder, the choice of heating method is directly related to the production efficiency and cost.

Electromagnetic heating has the feature of high efficiency and uniformity, which is suitable for the production environment with high requirements; ceramic heating is suitable for the production of special plastic materials, with the feature of fast response speed; and ordinary electric heating is an economical choice, which is suitable for some production scenarios with medium and low-temperature requirements.

In the actual application, according to the production demand and budget, choosing the appropriate heating method will be more conducive to the stable and efficient operation of plastic pelletizing extruders.