Are you looking for an efficient, reliable method to process textile waste, industrial fibers, or old garments? A professional fiber cutting machine is the key equipment for transforming waste materials into valuable, renewable resources. This article will detail how our textile cutting machine can help you boost production efficiency, reduce costs, and create new opportunities for your recycling business.

In industries such as textiles, non-woven fabric manufacturing, automotive interiors, and composite materials, the precise and uniform cutting of fibers is a critical first step. Whether you need to prepare raw materials for an opening machine, or produce short fibers for fillings, insulation, or construction materials, a high-performance textile fiber cutting machine is an indispensable asset on your production line.

Why Your Business Needs a Fiber Cutting Machine

Our fabric waste cutting machine is designed to solve the core challenges in fiber processing and fiber recycling, bringing you significant business advantages:

- Turn Waste into Value: Efficiently cuts various textile scraps, fabric remnants, yarn waste, and old clothes into short fibers of uniform length, turning them into valuable raw materials for reproduction.

- Improve Subsequent Process Efficiency: The uniformly cut fibers are ideal for direct feeding into an Opening Machine, carding machine, or blending equipment, thereby increasing the output and final product quality of the entire production line.

- Wide Material Compatibility: Our machine not only processes conventional textiles like cotton, linen, and synthetic fibers but also effectively cuts high-strength industrial fibers such as glass fiber and aramid fiber.

- Simple Operation, Reduced Labor Costs: Equipped with a feeding conveyor belt and an independent electrical control cabinet, it enables continuous, stable, and automated production, significantly reducing manual intervention and labor intensity.

Wide Range of Applications & Suitable Materials

Our fiber cutting machine, also known as a textile cutting machine or waste cloth cutting machine, has a powerful versatility that makes it suitable for numerous industries:

Applicable Materials: Old clothes, fabric scraps, yarn waste, fishing nets, non-woven fabrics, leather, glass fiber, aramid fiber, synthetic fibers, carpets, and more.

Application Industries:

- Textile Recycling and Reuse

- Non-woven Fabric Production (e.g., needle-punched cotton, sound insulation cotton)

- Automotive Interior Material Manufacturing

- Building Materials (e.g., thermal and acoustic insulation)

- Filler Production (e.g., for toys, pillows, sofas)

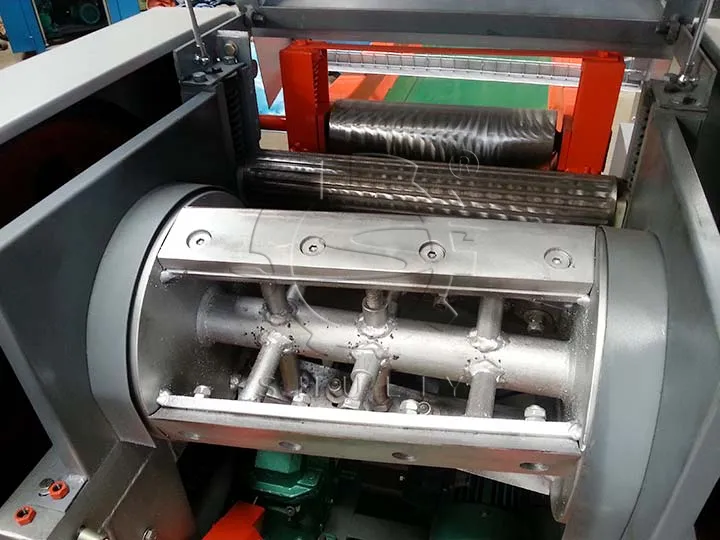

Working Principle & Core Design

Our fiber cutting machine utilizes an advanced and reliable shearing design to ensure efficient and precise cutting results.

Its core structure includes a set of high-speed rotating movable blades and a set of fixed blades. As materials are fed into the machine via the conveyor belt, the multiple blades on the movable roller rotate at high speed, creating a scissor-like cutting action against the fixed blade. This design ensures a clean cut, consistent fiber length, and effectively prevents fiber entanglement and blockages. The machine features a reasonable structure, stable operation, and easy maintenance.

Working Video of Fabric Waste Cutting Machine

Choosing the Right Model: Technical Parameters Overview

To meet the production needs of businesses of all sizes, we offer a range of models from small to large scale. Below are the technical specifications of our main models to help you make the best choice:

| Model | Capacity | Power | Cut Size | Cut Thickness | Dimension |

| SL-300 | 300 kg/h | 3 kw | 5—300 mm (fixed one size) | 20 mm | 1865*1120*1220 mm |

| SL-500 | 500 kg/h | 4 kw | 5—300 mm (fixed one size) | 20 mm | 3220*1160*1260 mm |

| SL-800 | 800 kg/h | 5.5 kw | 5—150 mm (Select 3 sizes) | 30 mm | 3500*1200*1300 mm |

| SL-1500 | 1500 kg/h | 9 kw | 5—150 mm (Select 3 sizes) | 30 mm-60 mm | 6000*1000*1100 mm |

Note: We can customize the machine’s cutting size and related configurations according to your specific requirements.

Enhance Your Fiber Processing Capabilities with Shuliy Machinery

Investing in a high-quality fiber cutting machine is a smart move to enhance your business’s competitiveness. It not only efficiently processes all types of fiber waste but also creates new opportunities for profit growth.

Shuliy Machinery is committed to providing high-quality, cost-effective equipment. Our machines are reasonably designed, easy to operate, safe, and reliable, and have been proven in production by numerous clients worldwide.

Contact us today for a detailed quotation and professional technical consultation. Let our experts help you choose the most suitable fiber cutting solution for your needs.