When purchasing and using a waste plastic pelletizing recycling line, customers usually have an in-depth understanding of a series of key issues to ensure that it meets their production needs. Below are some customer concerns and related answers.

Can It Handle Different Raw Material Types?

The first concern of the customer is whether the same waste plastic pelletizing recycling line can handle different types of raw materials. Some customers have more than one type of raw material, there may be PP, PE, PET, PVC, PS, and other different plastic products.

According to professional technical analyses, different raw materials have unique physical and chemical properties, such as different melting points. Therefore, it is difficult to adapt the same waste plastic granulation line to a wide range of feedstocks at the same time, as each feedstock needs to be adapted accordingly to its characteristics.

What Is The Power Consumption Of The Whole Line?

Power consumption is a cost factor that manufacturers are generally concerned about. Taking the processing of one tonne of plastic raw material as an example, the power consumption of a waste plastic pelletizing recycling line is usually around 500 degrees. This figure is influenced by the technical level of the line, the effectiveness of the equipment, and the production parameters.

How Many Workers Are Required To Operate?

Under the consideration of labor cost and production efficiency, customers are concerned about how many workers are needed to operate the whole waste plastic granulation line. Generally speaking, a team of 3-4 operators is sufficient to support the normal operation of the production line.

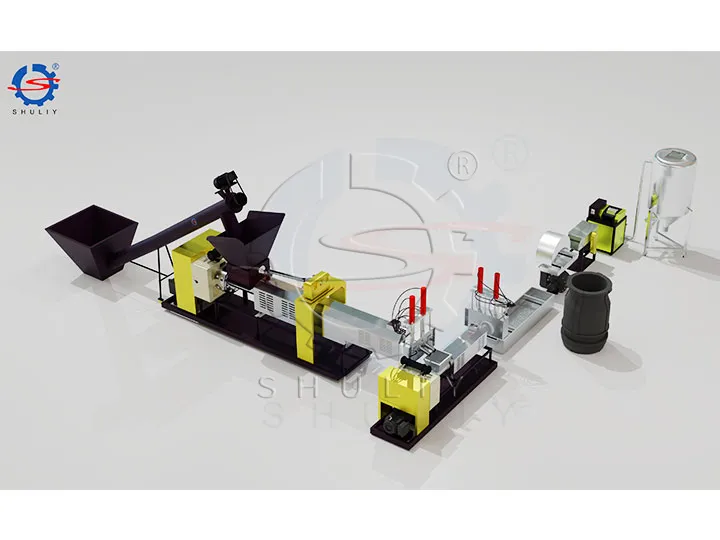

space needed for waste plastic Pelletizing Recycling Line

Customers are also often concerned about whether or not there is enough space in the factory to accommodate a waste plastic granulation line. On this issue, we can offer several different line placements depending on the customer’s plant design to ensure that limited space is maximized and production needs are met.