Plastic waste recycling equipment is a key technology through which we can effectively process all kinds of waste plastics and give them a new life. This technology not only makes full use of plastics but also provides high-quality recycled materials for various industries. This article will look at recyclable plastics that can be recovered through automatic plastics recycling machines, providing readers with an overview of the importance and practical applications of this environmentally friendly initiative.

The Role Of Plastic Waste Recycling Equipment

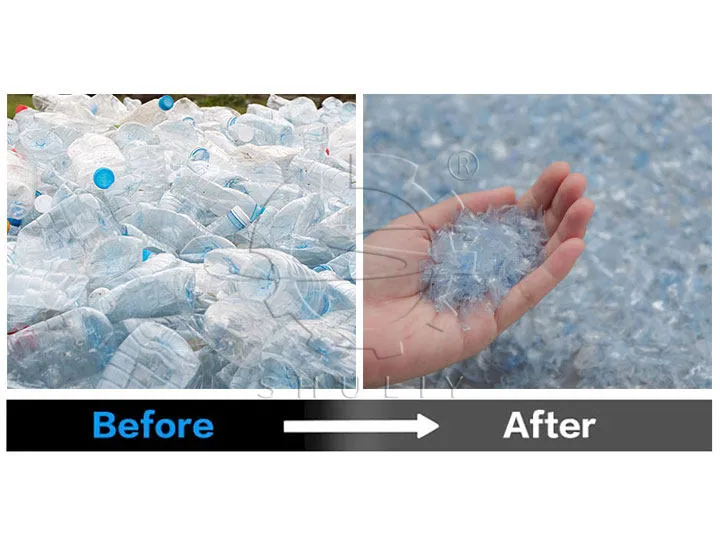

The automatic plastic recycling machine is a piece of equipment specifically designed to take waste plastic and process it. Through crushing, washing, and granulating technologies, plastic waste recycling equipment is able to convert waste plastics of various shapes and types into recycled plastic pellets, enabling the reuse of resources.

Different Types Of Recyclable Plastics

PET (Polyethylene Terephthalate)

PET is a common plastic widely used in beverage bottles, food packaging, and more. Through shredding, separation, and washing in PET bottle recycling machines, waste PET can be recovered and processed into recycled plastics that can be used to make new packaging materials, fibers, and more.

HDPE (High-Density Polyethylene)

HDPE is mainly used to make packaging containers such as bottles, containers, and drums. After being processed in plastic waste recycling equipment, waste HDPE can be efficiently recycled into recycled plastic pellets, which are applied to make a variety of durable plastic products.

PP (Polypropylene)

PP is commonly used in food packaging and household products. Automatic plastic recycling machines are able to process waste PP into high-quality recycled plastic, providing a reliable raw material for the manufacturing industry.

LDPE (Low-Density Polyethylene)

LDPE is mainly used for plastic bags, packaging films, and so on. Through plastic waste recycling equipment, waste LDPE can be efficiently processed into recycled plastics, which are used to make various packaging materials.

Practical Benefits Of Plastics Recycling

The practical benefits of using plastic waste recycling equipment to recover recyclable plastics lie not only in the disposal of waste but also in the provision of economically viable recycled raw materials for various industries. Through this process, we are able to minimize the production of new plastics, save resources, reduce production costs, and create greater profit margins for businesses.

The wide application of plastic waste recycling equipment allows waste plastics to be processed efficiently, providing the manufacturing industry with a rich source of renewable resources. If you have a large amount of waste plastics and don’t know how to recycle them or need to choose the right recycling machine according to the raw materials, you can consult us. We can customize the production line according to your raw material type and plant area, as well as provide you with installation guidance and after-sales service.