In the tire recycling process, handling the bead portion—the thick, steel-reinforced edge of the tire—is often a challenge. After tire bead rings are removed using a tire bead cutting machine, the next step is to separate the embedded steel wires from the rubber. The tire steel wire separator is specifically designed for this purpose, enabling clean separation of steel and rubber for further processing.

How the Tire Steel Wire Separator Works

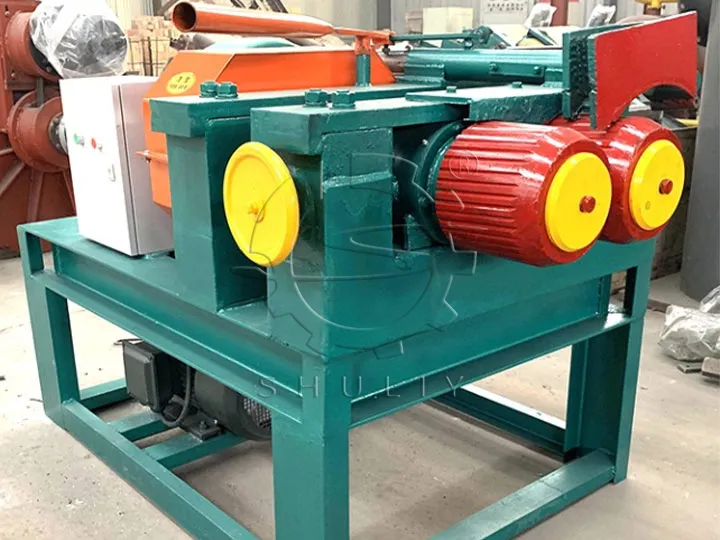

This machine uses a dual-roller compression mechanism. The bead ring section is fed between two heavy-duty rotating rollers, which apply controlled pressure to strip out the internal steel wire while simultaneously flattening and separating the surrounding rubber.

Key Features:

- Roller Gap Adjustment: Adaptable to different bead thicknesses

- Processing Method: Dual hard-alloy rollers for mechanical extrusion

- Separation Efficiency: High steel extraction rate with minimal rubber contamination

- Structure: Stable frame with low maintenance requirements

Application Range of The Steel Wire Separator

- Suitable for tire bead rings from tires up to 1200 mm in diameter

- Optional models available for larger tires exceeding 1200 mm, equipped with reinforced rollers

- Compatible with various waste tire types including passenger car, truck, and light commercial vehicle tires

Downstream Integration

Once the steel wire and rubber are separated:

- The recovered rubber can be shredded in a tire shredder and then processed into rubber powder or granules in a rubber powder mill.

- The extracted steel can be collected and sold for recycling, reducing material waste and adding value to the recycling process.

Advantages of the Tire Steel Wire Separator

- Reduces wear on shredders: By removing steel, shredders and mills face less mechanical stress

- Improves product purity: Clean rubber and steel fractions ensure better quality of rubber granules or rubber powder

- Adjustable roller gap: Accommodates varying tire bead sizes and thicknesses

- Built to last: Equipped with wear-resistant alloy rollers for long-term operation

Why Choose Our Equipment?

Our tire steel wire separator is built for tyre recycle plants that value durability, adaptability, and consistent performance. We offer models for standard and large tire beads and can help you integrate this machine into your semi-automatic or full rubber powder production line.

Contact Us for a Complete Tire Recycling Solution

In addition to the tire steel wire separator, we provide full pre-treatment solutions including tire sidewall cutters, strip cutters, block cutters, and rubber crusher machines. Reach out to us for customized layouts, technical advice, and a quote tailored to your specific tire recycling needs.