Mstari wa uzalishaji wa matofali ya barafu kavu ni mfumo kamili ulioundwa ili kusindika dioksidi kaboni ya kioevu kuwa matofali ya barafu kavu yaliyosimama. Mstari mzima wa uzalishaji huanza na pelletizing ya barafu kavu, ikifuatiwa na kubana matofali, usafirishaji wa moja kwa moja, na ufungaji wa mwisho. Inawawezesha uzalishaji wa matofali ya barafu kavu wa kuendelea na thabiti na inatumika sana katika usafirishaji wa mnyororo baridi, usindikaji wa vyakula, kupoza kwa viwanda, na nyanja zinazohusiana.

Kwa nini Uwekezaje Katika Mstari wa Utengenezaji wa Matofali ya Barafu Kavu?

Kwa mashirika yanayohitaji kiasi kikubwa au matumizi ya mara kwa mara ya matofali ya barafu kavu, uzalishaji wa ndani hutoa faida kubwa za kiuchumi na uendeshaji. Kuwekeza kwenye mstari kamili wa uzalishaji kunamaanisha unaweza:

- Punguza Gharama: Kwa muda mrefu, gharama ya kuzalisha barafu kavu yako mwenyewe ni ya chini sana kuliko kununua kwa kuendelea, na kusababisha akiba kubwa.

- Ongeza Ufanisi: Mstari wa uzalishaji wa moja kwa moja hupunguza sana kazi ya mikono, kuruhusu uzalishaji wa masaa 24 kwa siku na matokeo thabiti na ufanisi mkubwa.

- Hakikisha Ugavi: Ondoa utegemezi kwa wasambazaji wa nje na uzalishaji wa mahitaji, kuepuka usumbufu wa biashara unaosababishwa na usumbufu wa usambazaji.

- Dhibiti Ubora: Dhibiti usafi na unene wa barafu kavu kutoka kwa chanzo, kuhakikisha bidhaa za ubora wa juu, unene mkubwa zinazodumu kwa muda mrefu.

Vipengele Vilivyoboreshwa vya Mstari Wetu wa Uzalishaji wa Matofali ya Barafu Kavu

Mchakato wa Pamoja Uliolingana

Hatua za pelletizing, kubonyeza matofali, usafirishaji, na ufungaji zinazoendana vizuri, kupunguza wakati wa kusimama wa kati na kuhakikisha mchakato wa uzalishaji wa kuendelea na thabiti.

Mipangilio ya Uwezo wa Kubadilika

Aina tofauti za mashine za pellet za barafu kavu na mashine za kubonyeza matofali zinaweza kuchaguliwa kulingana na mahitaji halisi ya uzalishaji, na kufanya mstari kuwa nafaa kwa miradi mbalimbali ya matofali ya barafu kavu.

Uundaji wa Matofali ya Barafu Kavu wa Kuendelea

Mchakato wa kubonyeza ni thabiti, na ukubwa wa block, unene, na msongamano vinaweza kudhibitiwa, vinavyorahisisha kuhifadhi, usafirishaji, na matumizi ya mwisho.

Kupunguza Kushughulikia kwa Mikono na Upotevu wa Vifaa

Mifumo ya usafirishaji huunganisha kila hatua ya uzalishaji, kupunguza kushughulikia kwa mikono na kusaidia kupunguza upotevu wa sublimation ya barafu kavu.

Ufungaji Rahisi na Upanuzi wa Baadaye

Mpangilio wa mstari mfupi huruhusu ufungaji na uanzishaji kwa urahisi, na nafasi iliyohifadhiwa kwa ajili ya nyongeza ya uwezo wa baadaye.

Matumizi Mengi ya Programu

Inafaa kwa usafirishaji wa mnyororo baridi, usafirishaji wa dawa, kupoza kwa viwanda, kusafisha kwa barafu kavu, na matumizi mengine ya matofali ya barafu kavu.

Muundo wa Jumla wa Mstari wa Uzalishaji wa Matofali ya Barafu Kavu

Kiwanda hiki cha uzalishaji wa barafu kavu kinajumuisha mashine kadhaa kuu zinazofanya kazi pamoja. Kila mchakato umeunganishwa kwa urahisi, na muundo mfupi na mtiririko wazi wa uendeshaji, kufanya uendeshaji wa kila siku na matengenezo kuwa rahisi.

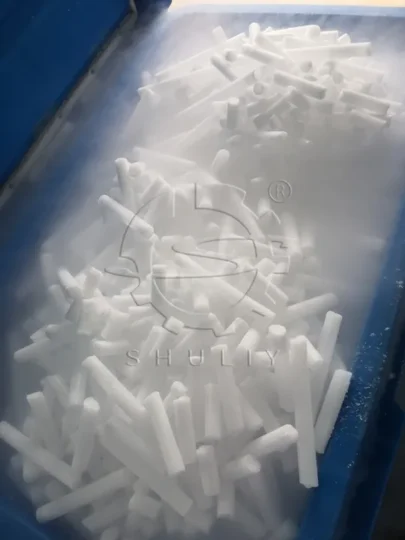

Mchakato wa Pelletizing wa Barafu Kavu

Hatua ya kwanza ya mstari wa uzalishaji ni uzalishaji wa pellets za barafu kavu. Dioksidi kaboni ya kioevu huenea kwa kasi na kupoa ndani ya mashine ya pellet ya barafu kavu, ikitengeneza pellets za barafu kavu za usawa. Hatua hii hutoa malighafi thabiti na ya kuaminika kwa mchakato wa kubonyeza matofali unaofuata, kwani pellets zinafaa kwa shinikizo na umbo.

Mchakato wa Kubonyeza Matofali ya Barafu Kavu

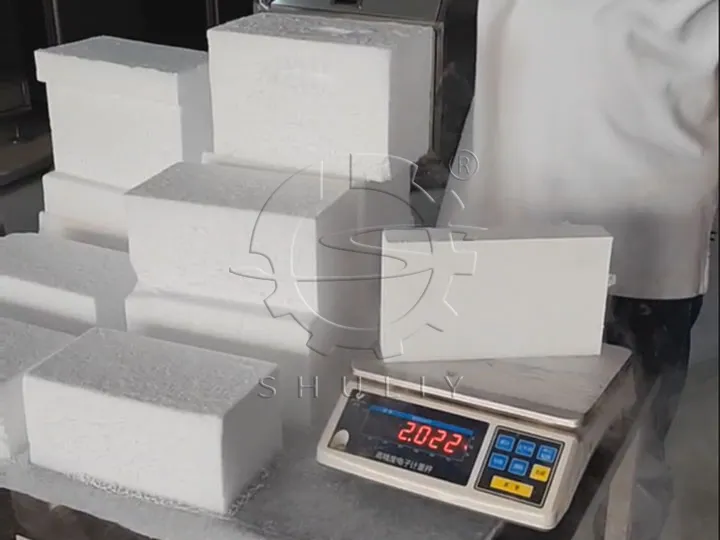

Baada ya pelletizing, pellets za barafu kavu huingizwa kwenye mashine ya kutengeneza matofali ya barafu kavu, ambapo zinachomwa kuwa matofali ya barafu kavu yenye umbo la kawaida. Kibonyeza matofali kinaweza kuzalisha matofali ya barafu kavu kwa saizi na unene tofauti kulingana na mahitaji ya uzalishaji. Mchakato wa kubonyeza ni thabiti, na matofali yaliyomalizika yana msongamano wa juu na muundo mzuri wa muundo, yanayofaa kwa kuhifadhi na usafirishaji.

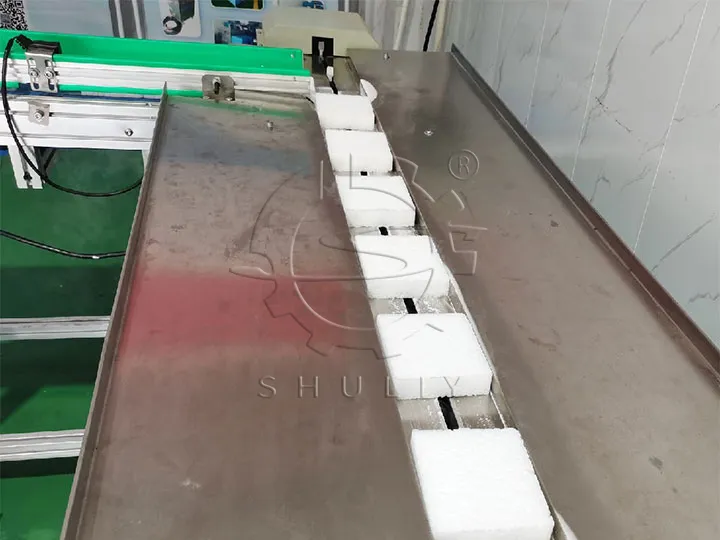

Mfumo wa Usafirishaji na Ufungaji wa Moja kwa Moja

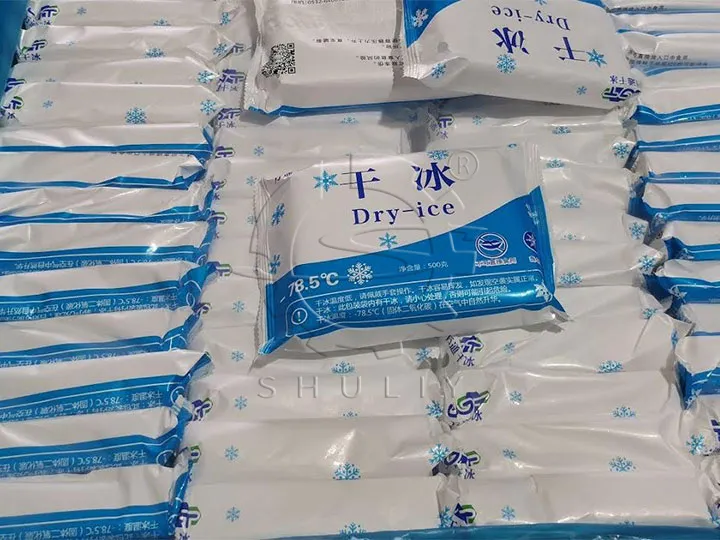

Matofali ya barafu kavu yaliyoundwa yanahamishiwa moja kwa moja kwa mfumo wa ufungaji kupitia kitengo cha usafirishaji, kupunguza kushughulikia kwa mikono na kupunguza upotevu wa vifaa. Njia ya ufungaji inaweza kubadilishwa kulingana na mahitaji ya mteja, kuruhusu matofali ya barafu kavu kuandaliwa kwa kuhifadhi kwa muda mfupi au kwa usafirishaji wa moja kwa moja. Hatua za usafirishaji na ufungaji zimeunganishwa vizuri ili kuboresha ufanisi wa jumla wa uzalishaji.

Video ya Uendeshaji wa Mstari wa Uzalishaji wa Matofali ya Barafu Kavu

Ni Nini Maeneo Makuu ya Maombi kwa Matofali ya Barafu Kavu?

Kwa joto lake la chini sana la -78.5°C na mali zisizo na mabaki, barafu kavu ina jukumu lisilobadilika katika nyanja nyingi.

- Usafirishaji wa Mnyororo Baridi: Ni refrigerant bora kwa kusafirisha vitu vinavyohitaji joto kama chanjo, dawa, na vyakula vya hali ya juu vya mbichi.

- Chakula na Huduma za Chakula: Inatumika kwa kuhifadhi chakula kwenye usafiri wa ndege, kupoza haraka wakati wa usindikaji wa chakula, na kutengeneza barafu na vinywaji maalum.

- Maombi ya Viwanda: Hutumika kama bidhaa inayotumika kwa kusafisha kwa barafu kavu ili kusafisha moldi za usahihi, vifaa, na zaidi.

- Utafiti wa Matibabu na Sayansi: Inatumika kwa uhifadhi wa muda mrefu wa plasma, sampuli za kibaolojia, na dawa.

- Athari za Jukwaa: Hutengeneza moshi wa kushangaza na mvua kwa matukio ya burudani.

Wasiliana nasi kwa maelezo ya Mstari wa Utengenezaji wa Matofali ya Barafu Kavu

Mstari wa uzalishaji wa matofali ya barafu kavu unajumuisha pelletizing ya barafu kavu, kusukuma matofali, usafirishaji, na ufungaji kuwa mchakato kamili na wa ufanisi. Kwa muundo wazi na uendeshaji thabiti, hutoa suluhisho la kuaminika kwa utengenezaji wa matofali ya barafu kavu.

Kwa habari zaidi kuhusu chaguzi tofauti za uwezo na specifications za kiufundi, tafadhali wasiliana nasi kwa suluhisho kamili la mstari wa uzalishaji wa matofali ya barafu kavu.