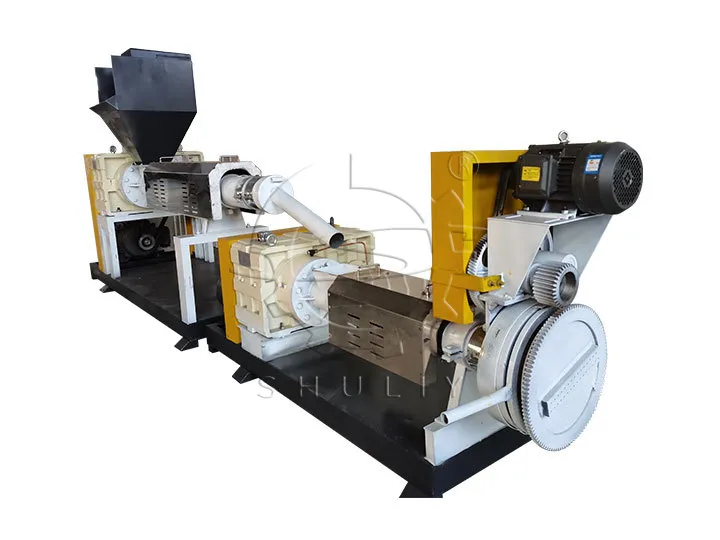

The rigid plastic granulator machine is designed to convert various rigid plastic wastes into high-quality, reusable recycled plastic pellets. Shuliy Machinery provides reliable solutions for the recycling of a wide range of rigid plastics such as HDPE, PVC, PP, ABS, PS, and others.

The machine is not only functionally optimized for hard materials, but is also highly efficient and energy-saving, meeting customers’ needs for both productivity and product quality.

Advantages of Strand Pelletizer

- Widely used materials: suitable for PP HDPE ABS PVC PS and many other plastic materials.

- Capacity to meet demand: our granulators have a capacity of 100kg/h-500kg/h. However, larger capacity machines can be customized according to customer requirements.

- Strong durability: made of high-quality materials and precision technology, the equipment is highly stable and reliable for long-term use.

- High customizability: provide customized service according to customer’s production needs, and can flexibly adjust the equipment configuration and parameters.

Rigid Plastic Granulator Machine Video

The material being processed in this video is PVC, and in addition to that, the equipment can process a wide range of materials. We will list them in detail below.

HDPE Granules Making Machine Applications

Our HDPE granules making machines are widely used for a wide range of rigid plastics, including HDPE bottles, drums, pipes, PVC pipes, profiles, window frames, PP bottle caps, plastic drums, containers, ABS electrical housings, household appliances, and car parts.

If you collect hard plastics such as HDPE bottles, containers, caps, etc, and want to find the right plastic recycling machine or a complete plastic recycling solution. Feel free to leave your message on our website, Our sales manager will contact you within 24 hours.

Recycled Plastic Granules

These wastes, after initial washing and crushing, become reusable raw materials for plastic granules. These recycled plastic pellets have a wide range of applications, especially in the plastic product manufacturing and recycling industries. These pellets can be re-introduced into the production chain for manufacturing plastic pipes, packaging materials, household goods, etc.

Rigid Plastic Granulator Machine Working Principle

The working principle of the pelletizer is also relatively simple to understand. The rigid plastic granulator machine is a kind of equipment used to process waste plastic materials into plastic granules by regeneration treatment, and its working principle mainly includes the following steps:

- Material feeding: Firstly, the waste plastic enters from the feeding port of the plastic granulator.

- Melting: The plastic is transported into the machine. Under the action of the heating device, the plastic is heated and melted into a molten state.

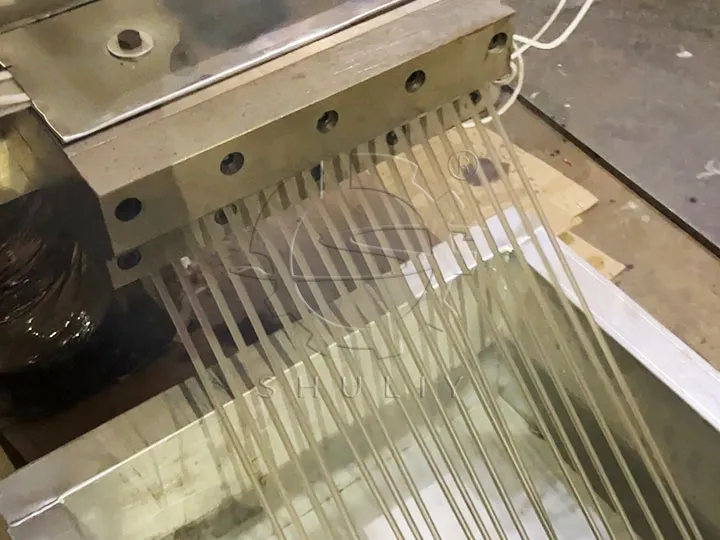

- Extrusion: Once the plastic is completely melted, it is pushed to the extrusion outlet of the machine. In this step, the molten plastic material is extruded through the extrusion mechanism of the die head to form granules of a certain shape.

- Cooling and Cutting: The extruded plastic lengths are further cooled and cured, and then cut into small pellets using a plastic pellet cutting machine.

Three Types Of Molds For Plastic Recycling Granulator

Regarding die heads, we offer different styles. Shuliy rigid plastic granulator machines are supplied with three different types of die heads, namely electric gear die heads, hydraulic die heads, and screenless slag discharge die heads. Each of these three types of die heads has its unique advantages and features and can be flexibly selected according to different plastic materials and production needs. Below you can see the strand pelletizer machine in action.

Plastic Pelletizing Recycling Machine Export Case

Plastic Recycling Granulator To Togo

Togo customers choose our plastic pelletizing recycling machines and personally come to our factory to complete the acceptance. We showed the customer the production process of the machine and the quality of the plastic granules produced, and the customer said it was very much in line with his expectations. Below is the video of the test run.

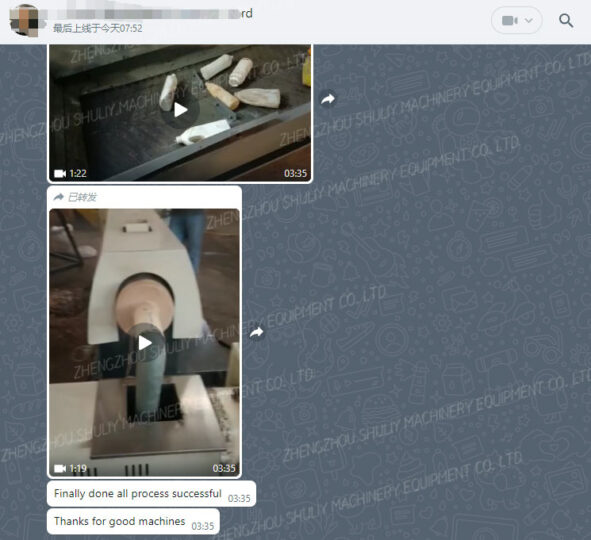

Feedback On The Ivorian Rigid Plastic Granulator Machine

A Cote d’Ivoire customer recently gave us feedback that the rigid plastic granulator machine he purchased from Shuliy Machinery has been successfully running and put into production.

More details: Feedback On Hard PP PE Pelletizing Line In Côte D’Ivoire

Parameters of Pelletizing Machine

| Capacity | 100kg/h-500kg/h |

| Applicable materials | HDPE bottles, drums, pipes, PVC pipes, profiles, window frames, PP bottle caps, plastic drums, containers, plastic flakes, ABS electrical housings, household appliances, and car parts |

| End product | Plastic granules |

| Heating method | Electromagnetic heating, ceramic heating, heating coils |

| Die head | Electric gear die heads, hydraulic die heads and screenless slag discharge die heads |

| Customizability | Customizable |

| Delivery date | 20-25days |

| Warranty | 1 year |

| Sold countries | Kenya, Ethiopia, Iran, Oman, Saudi Arabia, Côte d’Ivoire, Ghana, Botswana, Mozambique, Germany, etc. |

Rigid Plastic Recycling Granulating Line

The plastic recycling granulator usually forms a rigid plastic recycling granulating line together with a hard plastic crusher, a plastic scrap washing machine, a horizontal dryer, and so on. Machine configuration, output, appearance, etc. can be customized according to customers’ needs. We provide online or on-site installation guidance, and we will try our best to solve any problems in the process of using the machine.

HDPE Pelletizing Machine Price

For specific rigid plastic granulator machine prices, welcome to contact us. We will provide personalized quotation plans according to your needs and scale, and make sure you get the most competitive price.