The EU’s interim political agreement to amend the “Waste Shipment Regulation” reached on Nov. 17, imposes strict controls on the export of waste plastics, aiming to reduce the flow of problematic waste outside the EU. This change presents both challenges and new opportunities for the waste plastic recycling machinery industry.

Background Of The EU’s Waste Plastics Control Policy

Only one-third of waste plastics are recycled in Europe, and half of the recycled waste plastics are exported outside the EU. As a result of the problems associated with the management of these waste plastics, the Council and the Parliament of the European Union decided to amend the Waste Shipment Regulation to specify the criteria and procedures for the export of waste plastics.

Challenges For Recycling Machinery

As controls on the import and export of plastic scrap escalate, so do the challenges facing the recycling machinery industry. First, plastic waste recycling equipment needs to adapt to stricter standards for sorting and classifying plastic scrap to ensure that recycled plastic scrap meets the new export standards. Secondly, the ban on plastic scrap exports to non-OECD countries may result in a restricted market scope for plastic waste recycling equipment companies, which will need to look for new market opportunities.

Recycling Equipment Development Opportunities

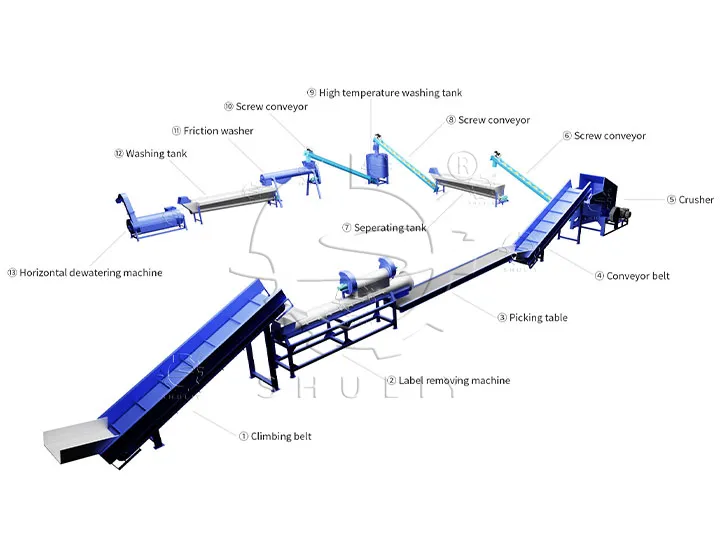

Under the new situation of the EU’s waste plastics control policy, the recycling machinery industry has also ushered in opportunities for development. Innovative technologies, especially the intelligent classification and sorting system commonly used in PET bottle recycling lines, can help recycling equipment meet waste plastic classification standards more accurately and improve recycling efficiency. This not only helps to meet export standards but also improves the competitiveness of enterprises.

Environmental Awareness Drives Market Demand

The implementation of the EU’s waste plastics control policy will guide enterprises and consumers to pay more attention to the environmentally friendly treatment of waste plastics, which will drive the demand for the waste plastics recycling machinery market. Plastic recycling machine manufacturers can meet the market demand for sustainable development and circular economy by providing advanced environmental protection technologies and realizing market share gains.

Opportunities For Global Circular Economy Cooperation

The revision of the EU Waste Shipment Regulation also provides an opportunity for global circular economy cooperation. Plastic recycling machine manufacturers can work together with non-OECD countries to develop standard-compliant waste plastics treatment programs, expanding the space for international cooperation and promoting the improvement of global waste management.

Under the new policy environment, the recycling machinery industry needs to continue to innovate, not only to meet the EU’s waste plastics control standards but also to adapt to the continuous upgrading of global waste management. Through technological development and industrial upgrading, the plastic waste recycling equipment industry can better adapt to the market demand.

In summary, the upgrading of the EU’s waste plastics control policy has brought new challenges to the recycling machinery industry but also provides opportunities for its development.