The plastic granule cutter is a very critical piece of equipment in a plastic granulation line, it is used to cut the long strip of plastic extruded from the plastic pelletizing machine into small pellets of uniform size.

We are a professional plastic recycling machine manufacturer, both product quality and service are guaranteed, and our plastic recycling machine has been exported to many countries and received a lot of praise. If you want to get the details of the machine, please feel free to leave us a message through the form on the website.

Plastic Pellet Cutting Machine Introduction

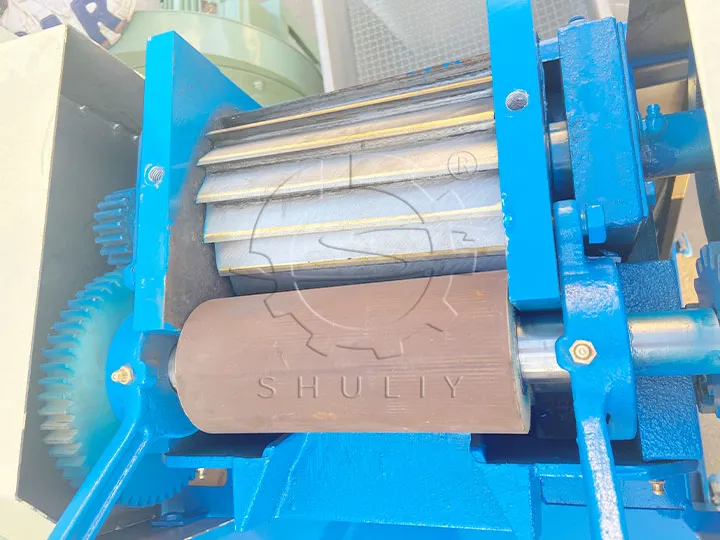

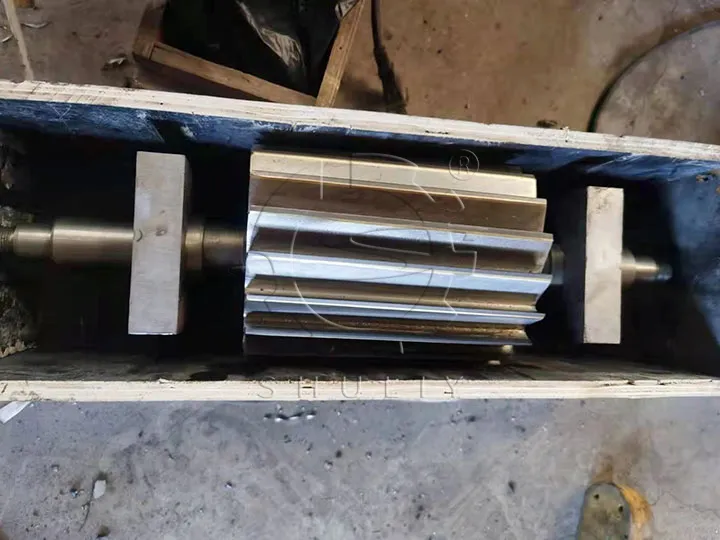

Our plastic pellet cutting machine is an easy-to-operate machine with superior performance. Its core feature lies in the use of carbide hobbing knives, which ensures that the blades rotate at high speeds, resulting in highly efficient cutting and high wear resistance. In addition, this plastic granule cutter has a very high degree of automation and adjustable cutting sizes to meet the needs of different customers. Whether you need to cut PP, PE, ABS, PVC, PET, EPE, EPS, or many other types of plastics, our plastic granules cutting machine is up to the task.

Application of Plastic Granule Cutter

The plastic granule cutter is widely used for cutting and pelletizing a wide range of plastic materials, including soft materials such as plastic bags, agricultural films, and woven bags, as well as hard materials such as plastic drums and pipes, and even EPE and EPS foams. This makes it an indispensable plastic recycling machine in a wide range of fields such as plastic film granulation lines, plastic granulation lines for rigid plastic, and plastic foam pelletizing lines. Whether it’s waste plastic recycling or recycled pellet production, plastic pellet cutting machines offer a reliable solution for the plastics industry with their excellent performance and flexibility.

How Does A Plastic Granule Cutter Work?

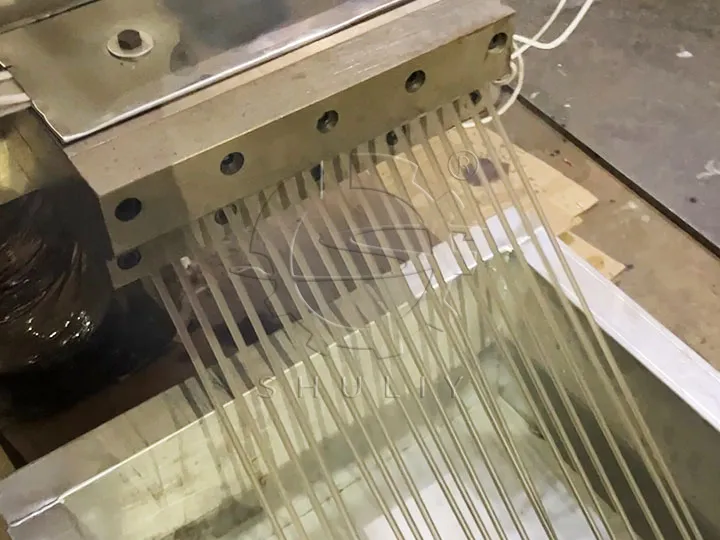

Firstly, the plastic is crushed and washed and then entered into the plastic pelletizing machine to melt and extrude into long strips, which are cooled and cured in a cooling tank. Then it enters into the plastic granules cutting machine, the pressure roller fixes the plastic strip tightly, and then it enters into the cutting room to cut it into small shaped granules.

Application Video

Structure of Plastic Granules Cutting Machine

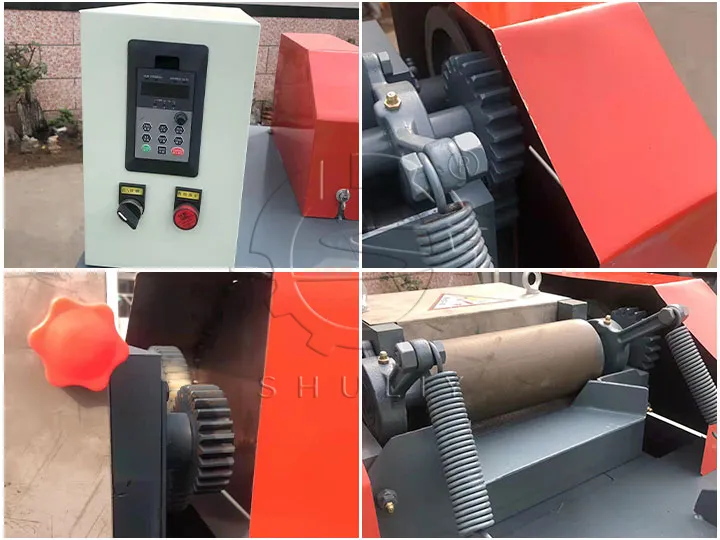

Our plastic granule cutter is mainly composed of a feed inlet, press wheel, rubber press wheel, motor, body, and discharge outlet. Among them, the rotary knife is made of a hard alloy hob, which has excellent wear resistance and ensures the long-lasting stability of the machine. In addition, the machine has two upper rollers and one lower roller, the upper roller material has two kinds of rubber rollers and iron rollers, and the lower roller only has iron rollers.

Detailed Information

Our Plastic pellet cutting machines are available in a wide range of models, from 2.2kw to 3kw, with outputs from 150kg/h to 280kg/h. The knives are hobbed, and the number and width of the blades vary according to the model. Appearance and model can be customized according to customer requirements. Welcome to contact us to get the quotation, model number, and specification of the plastic Dana cutting machine.