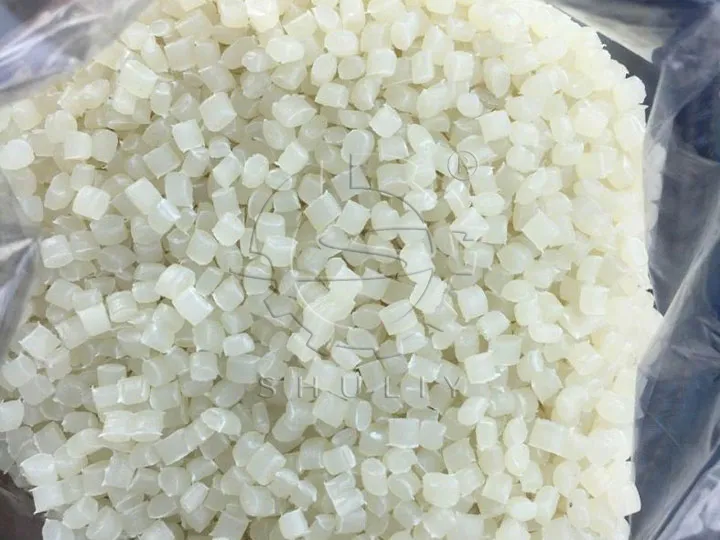

The plastic film granulator is a specialized machine designed to convert waste plastic film into small granular plastic pellets through a specific process. These plastic granules have reusable properties and can be used to produce new plastic products for the resourceful reuse of waste. The machine is highly efficient and precise in processing various plastic films such as packaging films, agricultural films, woven bags, stretch films, etc.

After you have read this article, if you are interested in our products or have any questions, please do not hesitate to contact us. Our team will be happy to provide you with more detailed information and personalized solutions to help you find the most suitable equipment for your needs. We look forward to working with you!

Raw Materials For Plastic Film Granulator

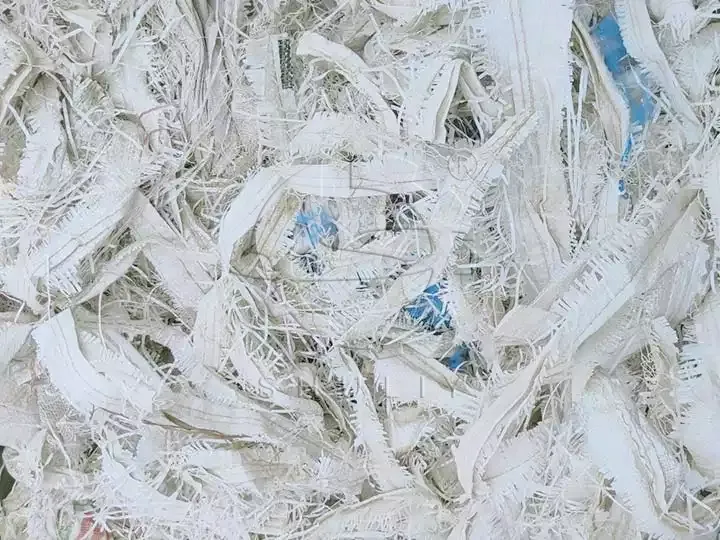

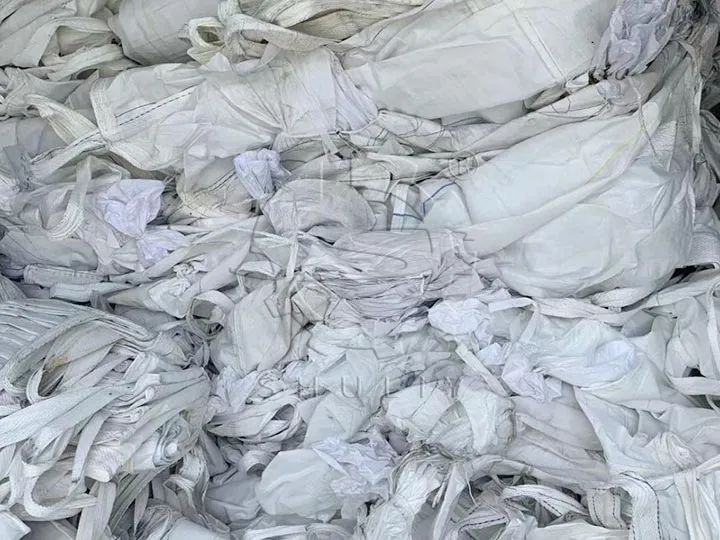

Plastic film pelletizing machines are typically capable of processing many types of plastic film waste, including but not limited to the following feedstocks:

- Plastic film: including a variety of packaging films, such as food packaging film, shopping bags, etc.

- PP woven bags

- Agricultural mulch film, greenhouse mulch film, and other discarded plastic film for agricultural use.

- Stretch film

- Industrial packaging film

- PP raffia bags

Film Granulator Application Video

Working Principle Of Film Granulator

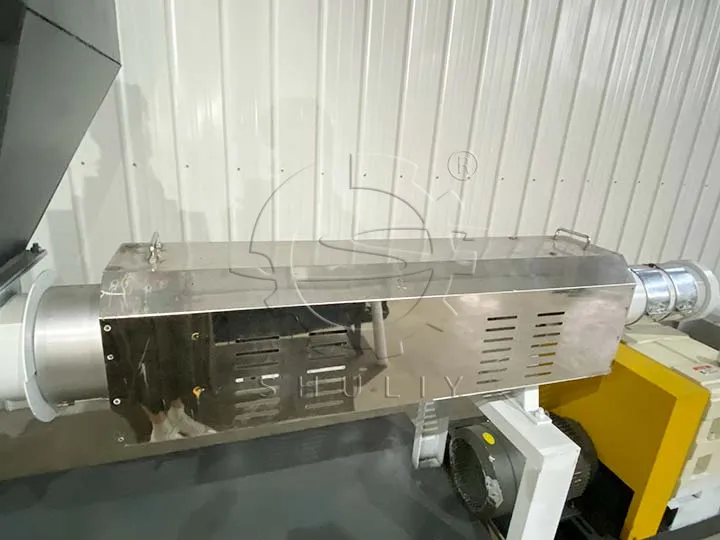

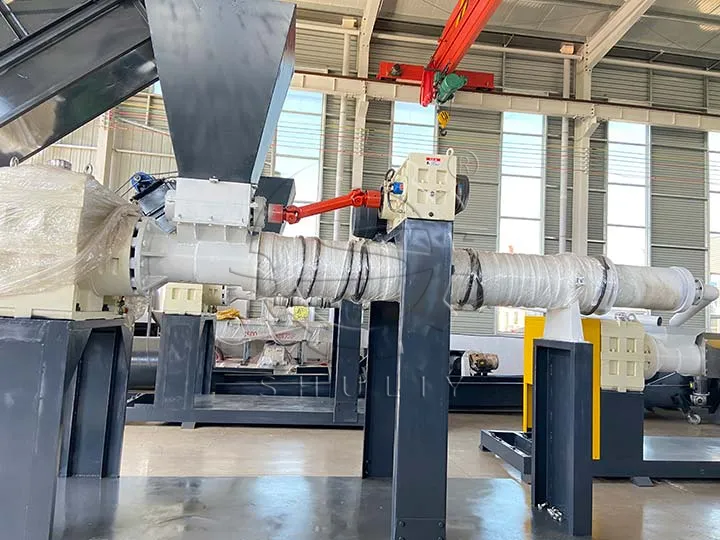

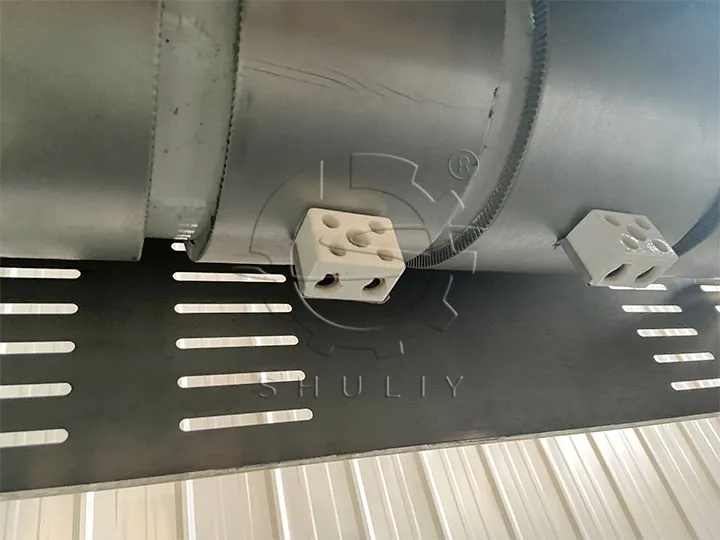

Plastic film granulator includes elements such as a feeding port, automatic feeder, reducer, various heating devices (such as electromagnetic, ceramic, and iron heating systems), screws, a motor, mold head, electric control cabinet, and so on.

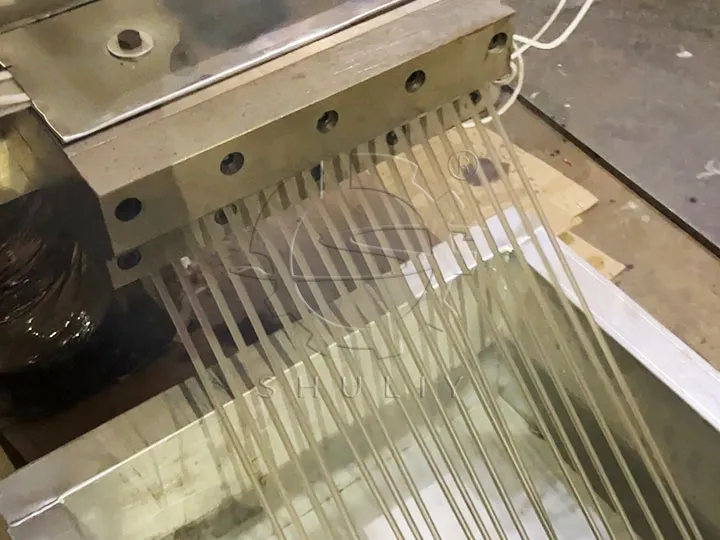

The working principle of the plastic film granulator is that the waste plastic film is conveyed into the machine through a charging port and an automatic feeding machine. Subsequently, the plastic is heated and melted and passes through the extrusion system to form a homogeneous melt, which is continuously extruded from the die by the screw under the pressure built up during the process.

Plastic Film Pelletizing Machine Heating Method

Electromagnetic heating: It is the most efficient heating method that can achieve rapid heating.

Ceramic heating: Ceramic heating has the characteristics of high-temperature stability, uniform heating, longer service life, etc. It is the heating method chosen by most customers.

Plastic Film Granulator Related Equipment

This equipment is used for crushing plastics for easy cleaning and pelletizing and can be used together with the plastic chips washing machine and plastic pelletizer machine to form a plastic recycling granulating line.

Plastic Scrap Washing And Drying Machine

This equipment is used to wash and dry crushed plastics, which are subsequently fed into a plastic film granulator for pelletizing.

Automatic Feeding Machine

This equipment is an auxiliary equipment for the plastic film pelletizing machine, which is used to convey lighter materials such as plastic film into the granulator with faster speed and more stable frequency, thus improving the production efficiency of the whole production line.

Film Granulator FAQs

What Temperature Is Required For Pelletizing?

If it is PP, PE granulation, the temperature of 240 degrees can be, and the machine working temperature can reach up to 500 degrees.

What Is The Material of Film Granulator Screw And Die Head?

38Ro Manganese Steel/40Ro

What Is The Diameter Of The Wire Extruded From The Die Head?

The diameter of the plastic strip extruded from the die head is 3.2 mm.

How Do I Make Different Colored Pellets?

It is sufficient to add the pigment during granulation, and the formula will be provided only after the order is placed.

Successful Cases Of Plastic Film Granulator

Plastic Film Pelletizing Machine Shipped To Saudi Arabia

A customer from Saudi Arabia recently ordered our waste plastic extrusion machine and it has been successfully delivered. The customer is going to use the machine to process LDPE and HDPE films into plastic pellets, we are looking forward to the customer’s feedback!

Plastic Granulator Machine Price

If you are looking for a plastic film granulator and are interested in pricing, we offer you a transparent and competitive plastic granulator machine price. Our prices take into account some factors such as machine performance, production capacity, and process innovation to ensure you get the best value for money. To get a detailed quote and learn more about our plastic film pelletizing machine, please feel free to contact us!