Pellet cutting machines are used to cut the plastic into plastic pellets after melting and pulling strips, and their blades are the key to cutting plastic raw materials into uniform pellets. Their design, material, and operating characteristics play an important role in determining the quality of the pellets produced.

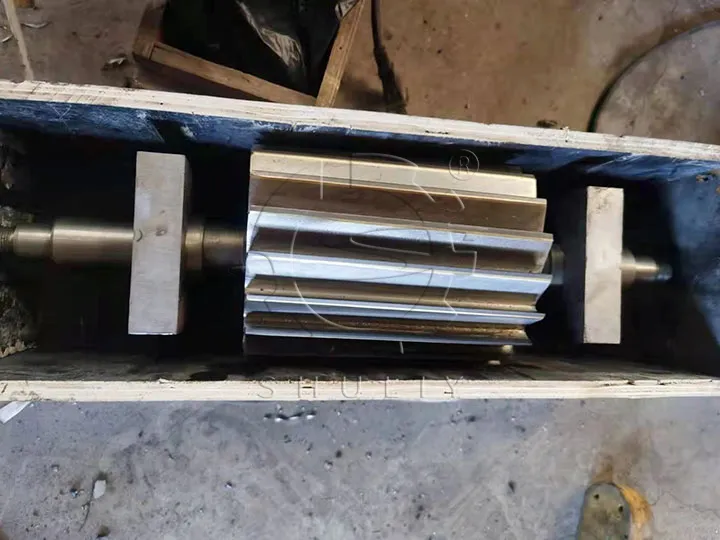

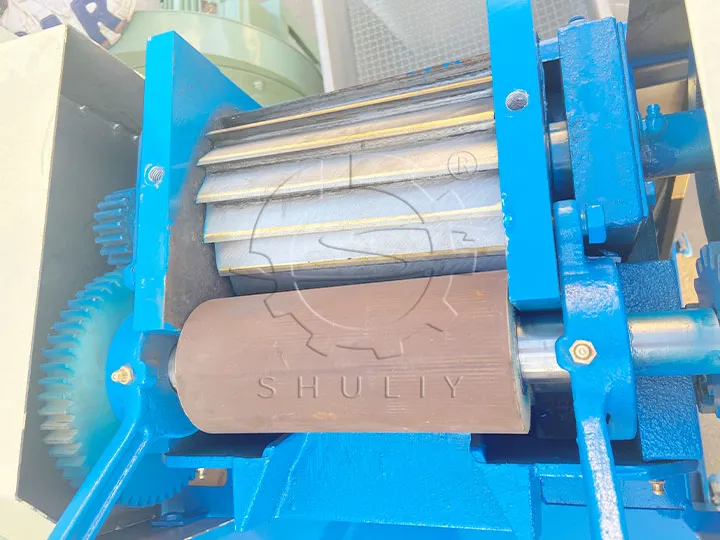

Blade Design And Material Choice

Blade construction plays a crucial role in ensuring efficient and consistent cutting. Plastic recycling machine manufacturers carefully conceptualize blade profiles, including shape, size, and cutting angle, to optimize the cutting process. The choice of blade material is equally important. Our pellet cutting machines are usually made of high-quality, durable materials such as carbide to withstand the mechanical stresses and wear and tear encountered during the cutting process.

Rotation Speed of Pellet Cutting Machine

High rotational speeds are a defining characteristic of these blades. The rotational speed is carefully selected according to the type of plastic to be processed, the required particle size, and the cutting chamber configuration. This enables the blades to cut the plastic material quickly and cleanly, resulting in precise, uniform pellets.

Friction And Lubrication

During the high-speed rotary cutting process, the friction between the blade and the plastic pellets generates heat and wear, which affects the cutting efficiency and precision. Regular lubrication can effectively reduce the friction, reduce the heat generated during the cutting process, prolong the service life of the blades, and at the same time ensure the quality of the granule cutting.

Blade Maintenance And Replacement

Given the high-speed nature of the blades and the abrasive nature of plastic materials, blade maintenance is critical. Regular inspection, sharpening, and replacement of worn blades ensures that the pellet cutter continues to operate at peak efficiency.