Are you looking to transform compacted, mixed textile waste into clean, fluffy, and high-value recycled fiber? A professional fiber opening machine is the core equipment to achieve this goal. This article will provide a detailed look at the working principle of the cotton opening machine, its key role in a production line, and help you select the most suitable model for your business to begin your efficient fiber recycling journey.

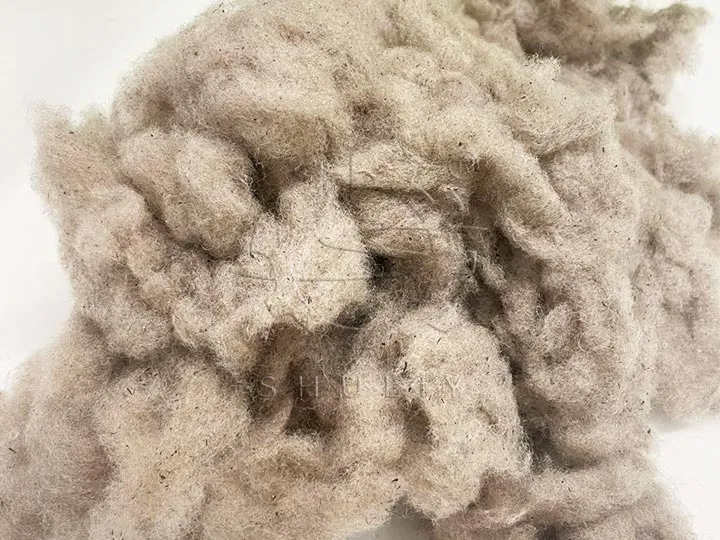

In the field of Fiber Recycling, simply cutting the raw material is not enough. To produce recycled fiber suitable for non-wovens, yarn spinning, or high-quality fillings, a critical process is required: opening and cleaning. The fiber opening machine, also often referred to as a cotton carding machine, is the specialist for this task. It effectively removes impurities from the fibers and cards the dense fiber clumps into a soft, fluffy, single-fiber state.

Why an Opening Machine is Essential for Your Recycling Business

- Improve Fiber Quality: Using high-speed rotating spiked rollers (licker-in), the machine effectively removes impurities such as dust, lint, and small debris from the fibers, yielding a cleaner, higher-quality recycled fiber.

- Achieve Thorough Fiber Opening: It can further break down and card the fiber blocks that have been processed by a Fiber Cutting Machine or a preliminary opener, restoring the fiber’s natural fluffiness and softness.

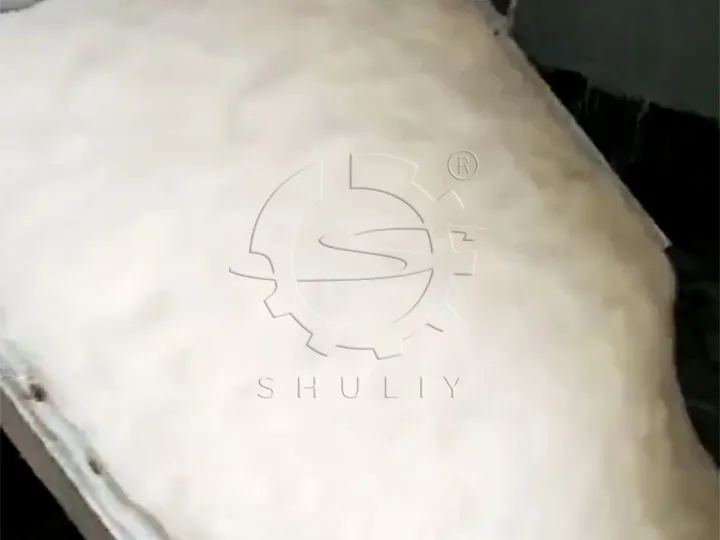

- Increase Final Product Value: Clean, fluffy recycled fiber is the ideal raw material for manufacturing high-grade non-woven fabrics, yarns, automotive interiors, sound insulation cotton, and fillings. Its market value is significantly higher than that of unprocessed waste.

- Modular Design, Easy to Expand: Our cleaner machines feature a multi-roller design, allowing you to flexibly choose the number of rollers based on your cleanliness requirements. A core principle is: the more rollers, the cleaner and fluffier the fiber.

The Role of the Fiber Opening Machine in a Production Line

Our cotton carding machine is designed to work in synergy with other related fiber recycling equipment to form a complete production line, maximizing efficiency. A typical production line process is as follows:

- Fiber Cutting Machine: First, large pieces of fabric, old clothes, or other raw materials are cut into uniformly sized smaller pieces, making them easier for subsequent equipment to process.

- Preliminary Fiber Opening Machine: The cut material undergoes an initial, powerful opening process to break apart its dense structure, preparing it for fine processing.

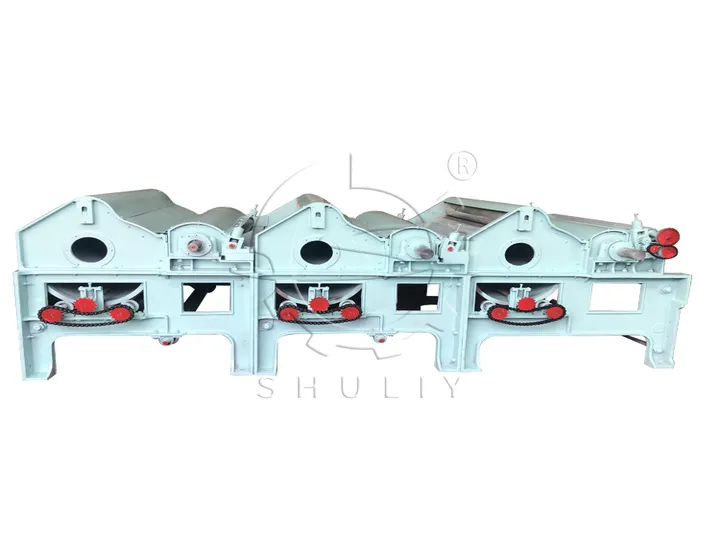

- Multi-Roller Cleaner Machine: This is the key stage. The material passes through multiple high-speed spiked rollers. Through centrifugal force, impurities are effectively separated and discharged, while the fibers are repeatedly carded, becoming cleaner and fluffier.

- Textile Baler Machine: The finished, clean fiber is compressed and baled for easy storage, transportation, and sale.

The Multi-Roller Design: Key to Fiber Quality

The heart of the fiber opening machine is its high-speed rotating rollers (licker-in). Covered in dense metallic card clothing (wire teeth), these rollers are crucial for efficient fiber opening and impurity removal. They aggressively grab and card fiber clumps, breaking them down into a single-fiber state.

Our modular, multi-roller design is based on a simple principle: the more rollers, the cleaner the fiber. This creates a progressive cleaning process. The first roller tackles large clumps and coarse impurities, while each subsequent roller performs finer opening and removes smaller particles like dust and lint. This method ensures the final recycled fiber achieves a high degree of purity and fluffiness.

Therefore, you can flexibly choose an cotton opening machine model with the appropriate number of rollers based on the impurity level of your raw materials and the quality requirements for your final product to achieve optimal cost-effectiveness.

Working Video of The Fiber Opening Machine

Our Hot-Selling Models: Detailed Technical Parameters

| Model | 400 | 600 |

| Roller Dia | 250 mm | 600 mm |

| Power | 28 KW | 18.5 kw |

| Capacity | 150 kg/h | 200-300 kg/h |

| Weight | Approx. 2.1 Ton | Approx. 1.1 Ton |

| Dimension | 5750 x 1500 x 1150 mm | 800 x 1700 x 1200 mm |

Note: The above fiber opening machine parameters can be adjusted and customized according to your specific requirements.

Invest in High-Quality Recycled Fiber with Shuliy Machinery

Investing in the right fiber opening machine is an investment in the quality and market competitiveness of your final product. It can transform low-value textile waste into high-quality recycled fiber that is highly sought after in the market.

Shuliy Machinery not only provides reliable and durable individual machines but can also design and build efficient, automated complete recycling production lines for you. Our professional team will tailor the best solution for you based on your raw material type, capacity goals, and quality requirements.

Contact us today for a detailed quote and expert advice, and let us help take your fiber recycling business to the next level!