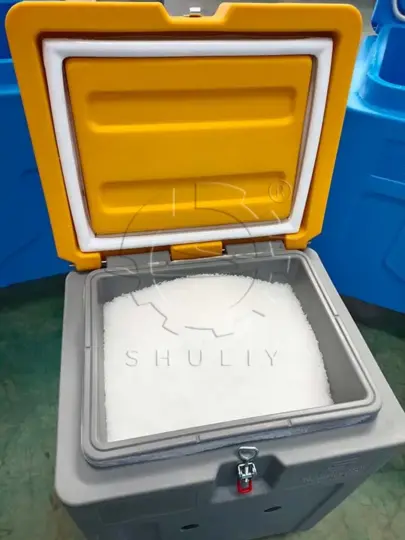

The dry ice storage box is a key piece of equipment designed specifically for the storage and transportation of solid carbon dioxide (dry ice). This type of insulated box is available in a variety of capacity options, ranging from 18L to 480L, and can also be custom-sized according to customer requirements.

Its core advantage lies in its excellent insulation performance, which can control the dry ice sublimation rate to as low as 4.2% per 24 hours, thereby minimizing loss across various applications. Through its effective insulation design, it significantly slows down the sublimation of dry ice, ensuring its quality and usability throughout the production, transportation, and usage stages. It is an indispensable part of the dry ice application industry chain.

Core Advantages and Features of Dry Ice Storage Box

Exceptional Insulation Performance

Our dry ice storage containers utilize high-efficiency polyurethane (PU) as the insulation filling material. Coupled with a thickened silicone sealing ring, the lid’s airtightness is significantly enhanced. This sophisticated design substantially reduces heat exchange between the interior and exterior, achieving a low dry ice sublimation rate of just 4.2% per 24 hours. This maximizes dry ice preservation, ultimately saving you costs.

Robust and Safe Materials

The walls of the dry ice storage box are constructed from food-grade PE (polyethylene) material, formed by rotational molding. This ensures it is non-toxic and harmless, making it safe for use in various industries such as food and pharmaceuticals. Furthermore, this material boasts excellent UV resistance, is fade-resistant, and maintains its robust structure and pristine appearance even in outdoor or challenging working conditions.

Convenient Mobility and Operation

To enhance operational flexibility, the bottom of the dry ice box is equipped with four heavy-duty casters, including two swivel casters with brakes and two fixed casters. This design allows the insulated container to be easily moved even when fully loaded, while the braking function ensures it can be securely fixed in place during operation, guaranteeing safety.

Flexible Integrated Applications

The design of our dry ice storage boxes fully considers their ability to work synergistically with various dry ice equipment, allowing for seamless integration into multiple operational workflows.

- With Dry Ice Pelletizers: The insulated container can be placed directly beneath the outlet of a dry ice pellet machine to collect freshly produced dry ice pellets, simplifying the production process.

- In Dry Ice Block Production Lines: In the production flow of dry ice blocks, the insulated container can serve as a temporary storage unit for packaged finished dry ice blocks, facilitating subsequent packaging or preparation for transport.

- Supporting Dry Ice Blasting: Operators can directly retrieve dry ice pellets from the insulated container to feed dry ice blasting machines, making cleaning operations more efficient and smooth.

Diverse Specifications and Customization Services

We offer a range of standard capacities from 18L to 315L to meet diverse user storage and transportation needs. Additionally, we provide customization services for dimensions based on your specific requirements. The following example uses the largest model of dry ice storage chest.

Materials and Structure

- Container Wall Material: Food-grade PE

- Insulation Material: Polyurethane (PU)

- Thermal Conductivity: 0.32 W/m²·K. Effectively reduces heat transfer and slows down dry ice sublimation.

Dimensions

- Overall Dimensions (L × W × H): 1100 × 700 × 1010 mm

- Internal Dimensions (L × W × H): 922 × 522 × 655 mm

Weight and Capacity

- Net Weight: 62–63 kg

- Internal Volume: 315 L

- Dry Ice Loading Capacity: Approx. 250 kg(Based on Φ3 mm dry ice pellets)

Dry Ice Storage Box For Sale

If you are looking for dry ice containers for sale that offer reliable insulation, durable food-grade materials, and practical designs for daily industrial use, our dry ice storage containers are a dependable choice. With multiple capacities available and proven low sublimation rates, they are suitable for dry ice production, storage, and transportation.

Leave us a message or contact our team to discuss your application, capacity requirements, and pricing—we’re happy to help you find the right solution.