Hello! When you’re in the market for an efficient and reliable dry ice block making machine, you’re likely asking yourself: Can this machine meet my specific product specifications? What’s its production capacity? And how easy is it to operate? We completely understand these crucial questions, as we know that the right equipment is fundamental to your business success.

Instead of overwhelming you with complex parameters and technical jargon, this article aims to have a conversation about how our dry ice block machines can genuinely benefit your operations.

Flexible Production to Meet Your Diverse Dry Ice Needs

We understand that various industries and applications have vastly different requirements for dry ice block specifications. Perhaps you need thinner blocks for catering and food preservation, or thicker, more substantial ones for cold chain logistics.

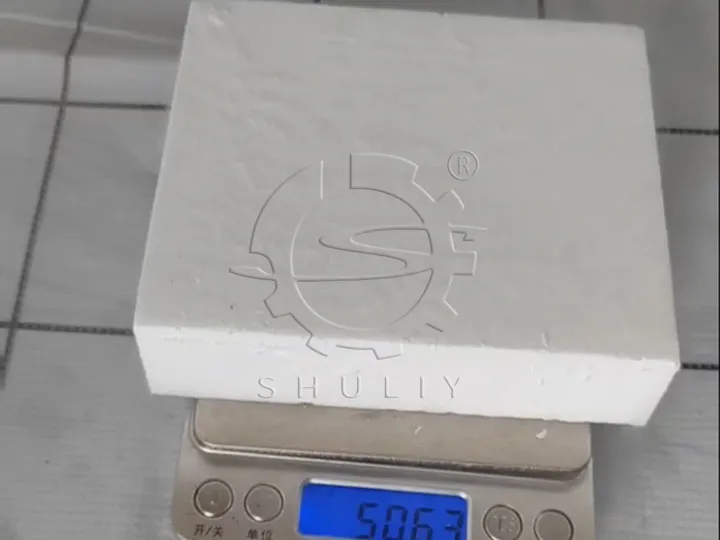

Rest assured, our dry ice block making machines are specifically designed with this flexibility in mind. You can easily adjust settings to produce dry ice blocks of varying thicknesses and weights to suit your precise requirements. This means you won’t need to invest in multiple machines for different specifications; a single unit can perfectly cater to your diverse market demands.

From Entry-Level to High-Volume: A Capacity for Every Business

What’s the scale of your current operations? Are you just starting out, or do you require large-scale mass production?

Our dry ice block making machine series offers a wide range of production capacities. Whether you need an entry-level capacity of 120 kg/hour or require high-volume production up to 1000 kg/hour, we have a model to match your needs. You can choose the perfect fit based on your current business volume and future growth plans.

Smart Control for Simplified Production

“Such a professional machine, will it be complicated to operate?” This is a very practical concern.

Please be assured that every one of our dry ice block making machines is equipped with an advanced PLC control system. This means the entire production process is highly automated, allowing you to set parameters and monitor operational status through an intuitive touchscreen interface. This not only significantly reduces operational difficulty, making it easy for your staff to get started, but also ensures stable and efficient production.

Applications of Dry Ice Blocks: Far More Than Just Preservation

You might be wondering, apart from cold chain transport and food preservation, where else can these dry ice blocks be used? The truth is, their applications are much broader than many people think.

- In cold chain logistics, its ultra-low temperature (-78.5°C) and residue-free sublimation make it the ideal choice for transporting high-end fresh produce, vaccines, and biological products. It turns directly from a solid to a gas, so unlike water ice, it won’t melt and leave your goods wet.

- For industrial cleaning, it’s used in a highly effective method called “dry ice blasting.” Dry ice particles are blasted at high pressure onto a surface, instantly vaporizing and carrying away contaminants. It works exceptionally well for cleaning molds, electronic components, and other delicate equipment, and it’s environmentally friendly with no secondary waste.

- In stage effects and catering, the “magical mist” effect we often see is created by dry ice sublimating in water. It adds a unique visual flair to banquets, performances, and culinary presentations.

Working Principle of a Dry Ice Block Making Machine

“How does liquid carbon dioxide turn into a solid block of dry ice?” It’s an interesting question, and the process is actually quite straightforward. You can think of it as a process of “making snow” and then “compressing the snow.”

- Step One: Rapidly ‘Making Snow’. We start by introducing liquid carbon dioxide from a storage tank. When this high-pressure liquid is rapidly released into the machine’s pressing chamber, the pressure drops suddenly. This causes the liquid CO2 to instantly expand and cool, forming a soft, snow-like solid we call “dry ice snow.”

- Step Two: Powerfully ‘Compressing the Snow’. Once the chamber is filled with this dry ice snow, a powerful hydraulic system activates, and a press head compresses the loose “snowflakes” with immense force.

- Step Three: Forming the Block. Under this tremendous pressure, the dry ice snow is compacted into a high-density, solid dry ice block. When the press head retracts, a brand-new block of dry ice is ejected.

More Than Just a Machine: Build a Complete Production Line

Perhaps your goal isn’t just to produce dry ice blocks, but to establish a complete dry ice production line, from raw material to finished product.

This is precisely where our strength lies. Our dry ice block making machines (we offer two main types as shown in the pictures, to suit different spatial and process layouts) can seamlessly integrate with dry ice pelletizers and automated packaging equipment to form an efficient, continuous fully automatic dry ice block production line. From manufacturing to packaging, the process is streamlined, maximizing your production efficiency.

Let’s Discuss Your Requirements

We believe that choosing a piece of equipment is choosing a partner. We aim to provide you with more than just a machine; we offer a solution that can create real value for your business.

If you are interested in our dry ice block making machine or would like to learn more about how to build your dry ice production line, please feel free to contact us. Let’s discuss your specific needs and recommend the most suitable equipment solution for you.