Cooling tanks play an important role in plastic pelletizing lines, and their main function is to rapidly cool hot plastic pellets from a high-temperature state to a suitable temperature for subsequent processing and handling. It is widely used in various plastic recycling granulating lines and helps to ensure the quality and stability of recycled plastic pellets.

Introduction of Cooling Tank

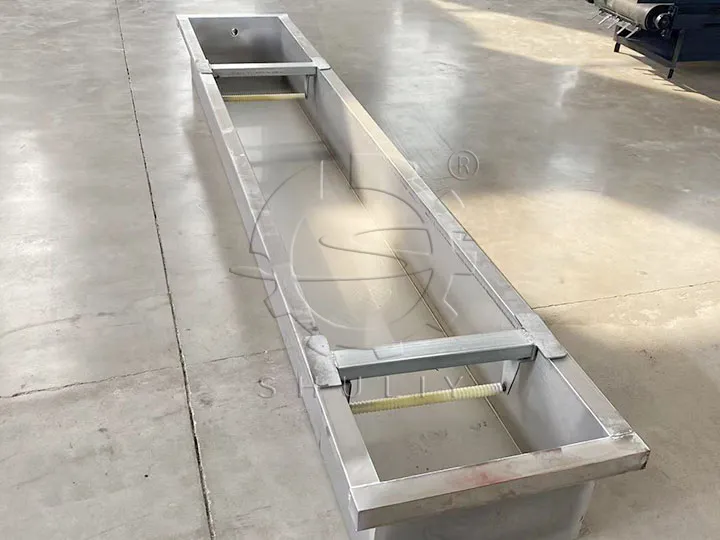

The plastic cooling machine is made of high-quality stainless steel for excellent corrosion resistance and durability. Cooling tanks play an important role in plastic granulators where the base lengths of plastic are soft and hot and cannot be cut into plastic pellets.

The Role of Plastic Cooling Machine

- Cooling plastic pellets: plastic cooling machines quickly cool hot plastic pellets to the desired temperature. This helps to stabilize the shape and size of the pellets.

- Curing: Rapid cooling helps to cure plastic pellets quickly to prevent them from distorting or melting during subsequent processing.

- Separation: After cooling, the plastic pellets do not stick together, making them easier to separate and handle and improving production efficiency.

Cooling Tank Size

The regular dimensions of our plastic cooling machines are 2.5m in length and 0.4m in width, but of course, we can also customize them to suit different production processes and requirements.