Among the large amount of packaging waste plastics generated globally daily, the PET bottle recycling rate has been the industry leader. However, the separation and processing of PET bottles and caps has been a bottleneck, limiting the efficiency of the entire recycling process.

Origin Materials, a California-based manufacturer of carbon-negative materials, recently announced that it has successfully achieved integrated recycling of PET bottles and caps through the manufacture of all PET caps, providing a more sustainable solution for post-consumer PET materials.

Product Features

Origin Materials’ all-PET bottle caps offer a range of compelling features:

- Patent pending can be produced using recycled PET (rPET) or bio-based PET for cost competitiveness.

- The “single material” design allows for “100% rPET” from cap to bottle, increasing recyclability and eliminating the need for recyclers to separate the cap from the bottle.

- PET has better oxygen and CO2 barrier properties than the common cap materials HDPE and PP.

All-PET Cap For Simplified Recycling

CPRRA’s research on PET bottle design for recyclability has shown that in the past, PE bottle caps accounted for the majority of the market. Due to the low coefficient of elasticity of PET material, conventional cap materials were not suitable and PE was usually chosen for caps and gaskets to ensure sealing. This leads to the need to separate the cap material from PET during the PET bottle recycling process, which is usually separated from PET by density sorting.

However, the introduction of all PET caps has brought a whole new way of thinking about the PET bottle recycling process. The adoption of all-PET caps is expected to further improve product quality by streamlining the process, increasing production efficiency, and reducing production costs.

All PET Bottle Cap, Recyclable And Reusable Design

CPRRA’s release of the “Guidelines for Recyclable Design of PET Container Packaging Products” provides standards for all PET bottle caps, emphasizing the need for recyclable design.

The adoption of an all-PET cap does not affect the recycling of PET bottles and is fully compliant with the requirements of recyclable and reusable design. This means that in the future, it will be easier for us to achieve efficient recycling of PET bottles, further promoting the development of the plastic packaging industry in a more sustainable direction. The introduction of the all-PET cap will be an important step in the recycling mechanism of PET bottles and a solid step forward for the cause of environmental protection.

Impact On PET Bottle Recycling Machines

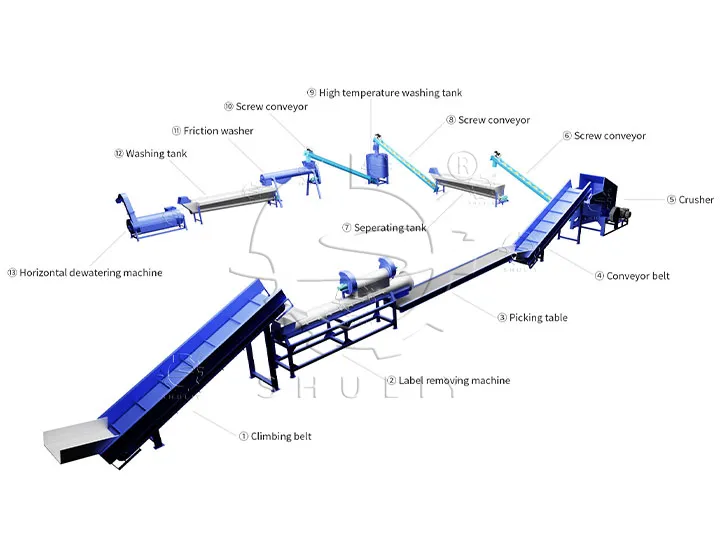

The emergence of all-PET bottle caps had a profound impact on the PET bottle recycling machine industry. Firstly, it reduces the burden of separating caps and bottles in the recycling process and improves recycling efficiency. Secondly, the unification of the material makes the recycling machine more efficient in cleaning and recycling PET bottles, which promotes the technological upgrading of the PET bottle recycling machine.

The introduction of all-PET closures not only brings higher recyclability and production efficiency to PET bottle recycling but also gives new impetus to a sustainable circular economy.