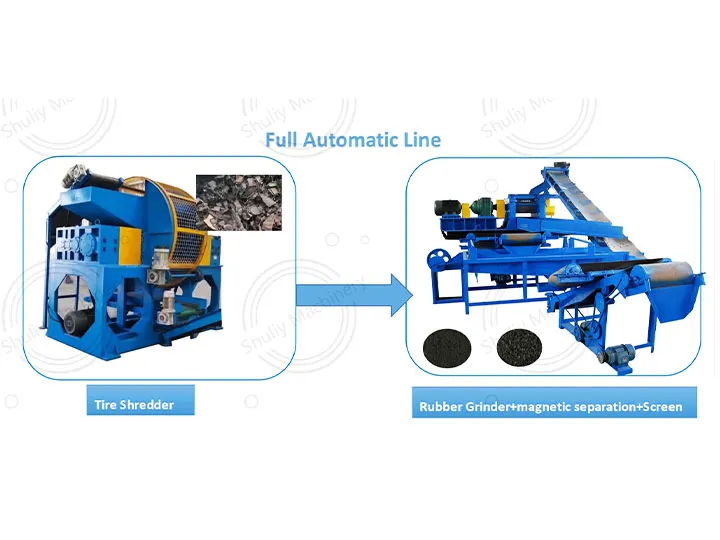

Our fully automatic waste tire recycling line is an advanced solution designed to process waste tires into clean, high-quality rubber granules or rubber powder, with minimal manual intervention. The system achieves full automation from shredding, grinding, screening, magnetic separation, fiber separation, to final material collection.

Raw Materials

Our fully automated tyre recycling lines are specifically designed to process all types of scrap tyres with a diameter of less than 1200mm, including car tyres, truck tyres and light engineering tyres. For larger tyres, such as OTR tyres, we also offer corresponding solutions.

Finished Product

After being processed by the fully automatic waste tire recycling line, the following finished products can be obtained:

- Rubber granules (1-5mm): used for runway, lawn filling, and rubber products manufacturing.

- Rubber powder (10-40 mesh): for recycled rubber production and rubber products processing.

- Steel wire: recovered by magnetic separation, used as raw material for smelting or reprocessing.

- Fibre impurities: separated by air separation, convenient for centralised treatment or recycling.

The purity of the finished rubber granules or powder can be as high as 99%, ensuring quality and stability for subsequent applications.

Key Features of The Waste Tire Recycling Line

- Tire Size Handling: Specially engineered for tires with a diameter of less than 1200mm, including car tires, truck tires, and light OTR tires.

- Final Products: Produces 1-5mm rubber granules or 10-40 mesh rubber powder, suitable for a wide range of applications.

- Flexible Capacity: Capable of handling production requirements from a few tons to several dozen tons per day, meeting the needs of both small and large recycling operations.

- Fully Automated Process: Reduces labor costs and boosts production efficiency with smart conveying, storage, and material separation systems.

Three Pre-treatment Solutions Available

To meet different customer needs and material conditions, we offer three pre-treatment options before the fine rubber grinding stage:

1, Tire Debeader + Tire Cutter + Shredder Line

- Tire Debeader: Removes steel wires from tire beads.

- Tire Cutter: Cuts tires into smaller sections.

- Tire Shredder: Shreds tire sections into rubber blocks.

- Intermediate Conveyor: Transfers materials automatically.

- Rubber Block Storage System: Stores shredded rubber blocks.

- Automatic Discharge Conveyor: Feeds material into the rubber powder machine.

- Rubber Crusher: Grinds blocks into granules or powder.

- Fiber Separator: Separates nylon fibers.

- Rubber Collection System: Collects and transfers final products.

2, Integrated Bead Cutter & Tire Cutter + Steel Wire Separator + Tire Shredder Line

- Bead Cutting and Tire Cutting Machine: Integrates cutting of tire beads and tire sections.

- Steel Wire Separator: Separates the embedded steel wire efficiently.

- Shredder and subsequent systems are the same as Solution 1.

3, Direct Shredding Line

- Tire Shredding Machine: Shred the tyre directly into small pieces. Suitable for tyres that have been pre-cut or have the beads removed.

- Followed by the intermediate conveyor, storage system, discharge conveyor, rubber crusher, fiber separator, and collection system as in the other solutions.

Why Choose Our Fully Automatic Waste Tire Recycling Line?

- High Automation: Minimize manual labor and maximize output stability.

- Modular Design: Easy to customize according to specific raw materials and end-product requirements.

- Efficient Separation: High-purity rubber granules and powder with steel wire and fiber content reduced to minimal levels.

- Reliable Performance: Built with durable components for long-term, continuous operation.