Rebar straightening machine is an essential equipment for processing bent or waste steel bars, widely used in steel recycling plants and construction material preparation. Our company provides a complete range of rebar straightening solutions, including multiple machine models for 6–25 mm steel bars, customized feeding ports, durable rollers, and strong dual-motor systems to ensure stable and efficient straightening performance. We also offer model selection guidance, factory testing, spare parts supply, and overseas technical support, helping customers quickly put the machine into operation.

Key Features of the Rebar Straightening Machine

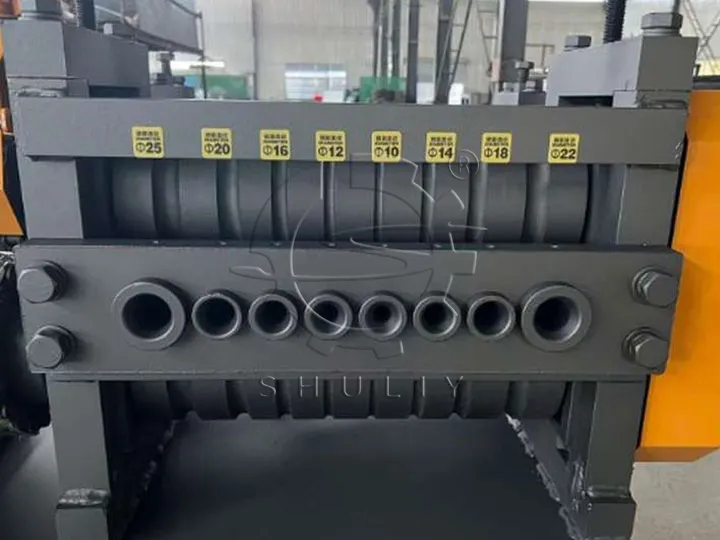

Multiple Feeding Holes for Different Diameters

Each model comes with multiple feeding holes. Operators simply select the hole that matches the steel bar diameter for smooth feeding.

In addition to round holes, T-type feeding ports are also available for faster and easier feeding.

Durable Thickened Straightening Rollers

The machine uses thickened wear-resistant rollers, extending service life and reducing replacement costs.

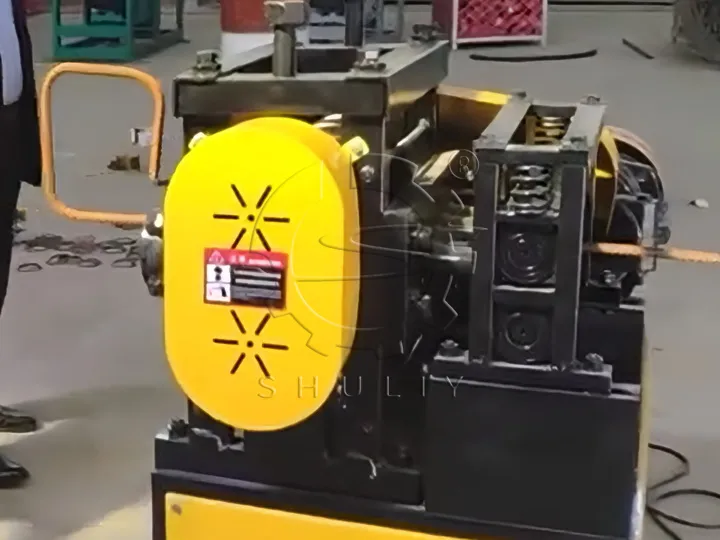

Stable and High-Efficiency Dual-Motor Drive

The dual-motor configuration delivers strong straightening force, allowing continuous operation with stable output.

Working Principle of the Rebar Straightener Machine

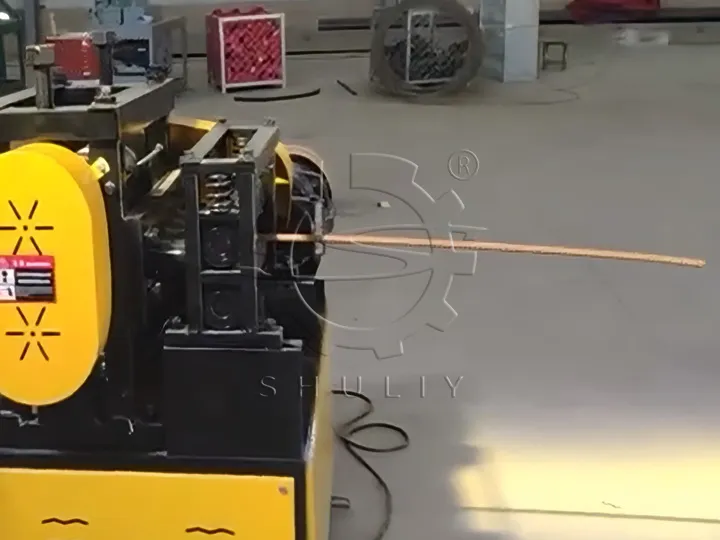

The rebar straightening machine works by feeding bent or waste steel bars through multiple straightening rollers driven by a dual-motor and reducer system. As the steel bar passes through the selected feeding hole, the rollers rotate at high speed, applying continuous pressure to remove bends and restore the bar to a straight condition.

The machine’s thickened rollers ensure stable force during straightening, while the matched feeding hole or optional T-type inlet helps guide different diameters smoothly into the system. After straightening, the steel bar is automatically delivered to the discharge section for collection or further processing.

Rebar Straightening Machine Models & Specifications

| Model | Straightening Rod Diameter | Inlet Holes | Straightening Length | Motor Power | Machine Weight | Machine Dimension |

| 6-10 | 6-10 mm | 5 holes | 500–2000 mm | 4 kW | 570 kg | 1100×720×1150 mm |

| 6-14 | 6-14 mm | 5 holes | 500–2000 mm | 5 kW | 730 kg | 1200×789×1220 mm |

| 8-16 | 8-16 mm | 5 holes | 500–2000 mm | 5 kW | 750 kg | 1250×820×1300 mm |

| 14-25 | 14-25 mm | 6 holes | 500–2000 mm | 15 kW | 980 kg | 1550×890×1600 mm |

Applications of the Steel Bar Straightening Machine

- Waste rebar recycling

- Construction site steel bar reuse

- Steel processing workshops

- Scrap steel bar straightening

- Metal recycling facilities

This rebar straightening machine helps restore bent or discarded rebars, improving material utilization and reducing waste.

Why Choose Our Rebar Straightening Machine?

- Supports a wide straightening range (6–25 mm)

- Strong dual-motor drive with smooth performance

- Multiple feeding holes + optional T-type inlet

- Durable rollers for long service life

- Stable operation with low failure rate

Request a Quote for the Rebar Straightener Machine

If you need a reliable rebar straightening machine for processing and recycling steel bars, feel free to contact us. Our team will recommend the suitable model according to your bar diameter, output requirements, and budget.

Related Rebar Processing Equipment

To support complete steel bar processing needs, we also provide related rebar processing machines. These include the rebar ring making machine for forming circular rings, the rebar stirrup bending machine for shaping construction stirrups, and the CNC pipe bending machine for precise bending of pipes or tubes. Our equipment caters to a wide range of processing requirements. Should you require our services, please do not hesitate to contact us.