干冰块生产线是一套设计用于将液态二氧化碳加工成固体干冰块的完整系统。整个生产线从干冰颗粒化开始,随后进行块压制、自动输送和最终包装。它实现了干冰块的连续稳定生产,广泛应用于冷链物流、食品加工、工业冷却及相关领域。

为什么投资干冰块生产线?

对于需要大量或连续使用干冰块的企业,内部生产具有显著的经济和运营优势。投资一条完整的生产线意味着您可以:

- 降低成本:从长远来看,自制干冰的成本远低于持续购买,节省大量开支。

- 提高效率:自动化生产线大大减少了人工劳动,实现24小时连续生产,产量稳定且高效。

- 确保供应:消除对外部供应商的依赖,实现按需生产,避免因供应中断带来的业务中断。

- 控制质量:从源头控制干冰的纯度和密度,确保高品质、高密度的产品,使用寿命更长。

我们干冰块生产线的优化特点

配套完整的集成工艺

颗粒化、块压制、输送和包装阶段协调良好,减少中间停机时间,确保连续稳定的生产过程。

灵活的容量配置

可以根据实际生产需求选择不同型号的干冰颗粒机和块压机,使生产线适用于各种规模的干冰块项目。

干冰块成型一致

压制过程稳定,块的尺寸、厚度和密度可控,便于存储、运输和最终使用。

减少人工操作和材料损失

输送系统连接每个生产阶段,最大限度减少人工操作,有助于减少干冰升华损失。

易于安装和未来扩展

紧凑的线布局便于安装调试,预留未来容量升级空间。

广泛的应用范围

适用于冷链物流、医药运输、工业冷却、干冰喷涂及其他干冰块应用。

干冰块生产线的整体配置

该干冰制造厂由多个核心机器协同工作组成。每个工艺环节连接顺畅,结构紧凑,操作流程清晰,便于日常操作和维护。

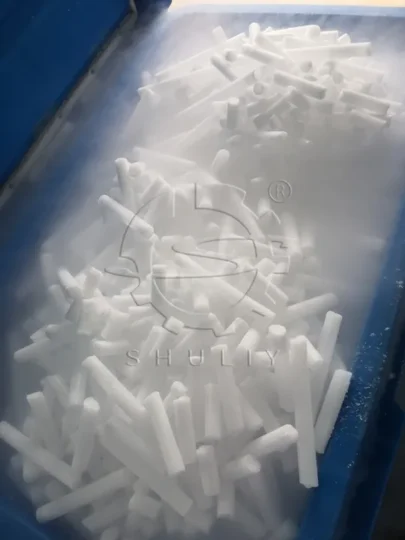

干冰颗粒化工艺

生产线的第一步是干冰颗粒的生产。液态二氧化碳在干冰颗粒机内迅速膨胀冷却,形成均匀的干冰颗粒。此阶段为后续的模压过程提供稳定且一致的原料,因为颗粒适合压缩和成型。

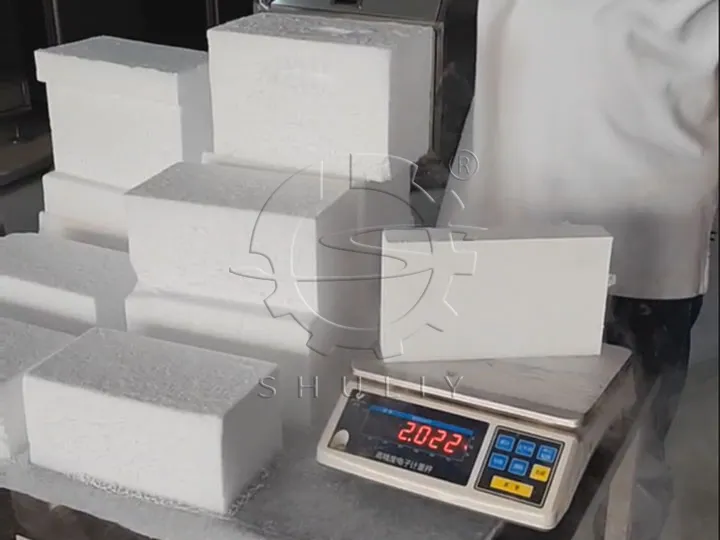

干冰块压制工艺

造粒后,干冰颗粒被送入干冰块制造机,在那里被压缩成规则形状的干冰块。模压机可以根据生产需求生产不同尺寸和厚度的干冰块。压制过程稳定,成品块密度高,结构完整,适合存储和运输。

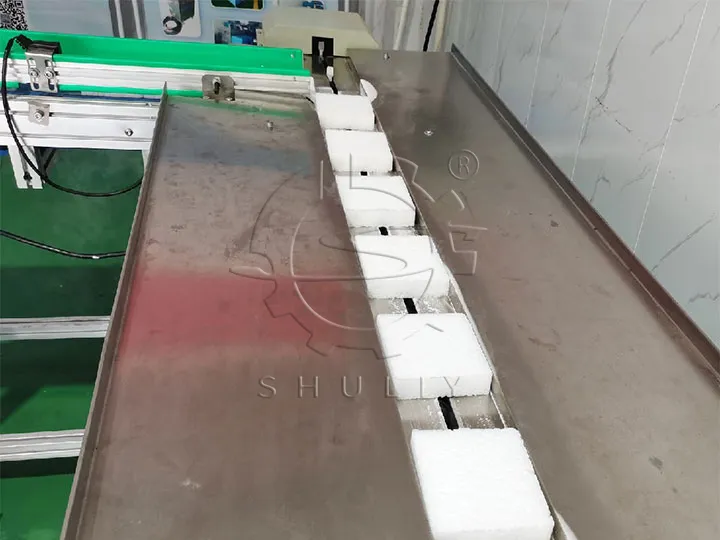

输送系统与自动包装

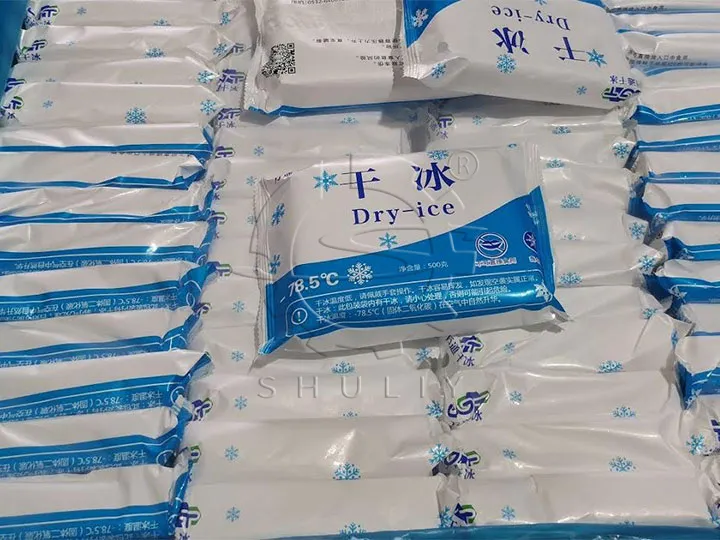

成型的干冰块通过输送装置自动传送到包装系统,减少人工操作,降低材料损耗。包装方式可根据客户需求进行配置,便于干冰块的短期存储或直接交付。输送和包装环节顺畅衔接,有助于提高整体生产效率。

干冰块生产线操作视频

干冰块的主要应用领域有哪些?

凭借-78.5°C的超低温和无残留特性,干冰在许多领域中发挥着不可或缺的作用。

- 冷链物流:是运输疫苗、药品和高端新鲜食品等温度敏感物品的理想制冷剂。

- 食品与餐饮:用于航空餐饮中的食品冷藏、食品加工中的快速冷却,以及制作冰淇淋和特色饮品。

- 工业应用:用作干冰喷砂的消耗品,用于清洗精密模具、设备等。

- 医疗与科学研究:用于血浆、生物样品和药品的长期低温保存。

- 舞台效果:营造壮观的雾气和云雾效果,用于娱乐活动。

联系我们获取干冰块生产线的详细信息

干冰块生产线将干冰颗粒化、压块、输送和包装集成为一个完整高效的生产流程。结构清晰,运行稳定,为干冰块制造提供可靠的解决方案。

如需了解不同容量选项和技术规格的详细信息,欢迎联系我们获取详细的干冰块生产线方案。