При операциях по переработке отработанных шин одним из важнейших этапов предварительной обработки является удаление внутренней стальной проволоки из шин. Этот шаг не только защищает последующее оборудование, но и улучшает качество конечных резиновых изделий. Дебидер для шин — это машина, специально разработанная для этой цели.

Что такое дебидер для шин?

Дебидер для шин — это гидравлическая машина, используемая для извлечения стальной кордной проволоки из внутреннего края отработанных шин. Эта машина является важнейшим компонентом на ранней стадии линии по производству резиновой крошки, подготавливая шины к измельчению или дроблению путем удаления прочных, армированных проволокой колец, которые трудно обрабатывать.

Наши модели дебидеров разработаны для работы с шинами диаметром до 1200 мм, что делает их идеальными для легковых и легких грузовых шин. Конечно, для более крупных шин, таких как шины OTR и шины для горнодобывающей промышленности, мы также предлагаем соответствующие модели.

Как работает дебидер для шин?

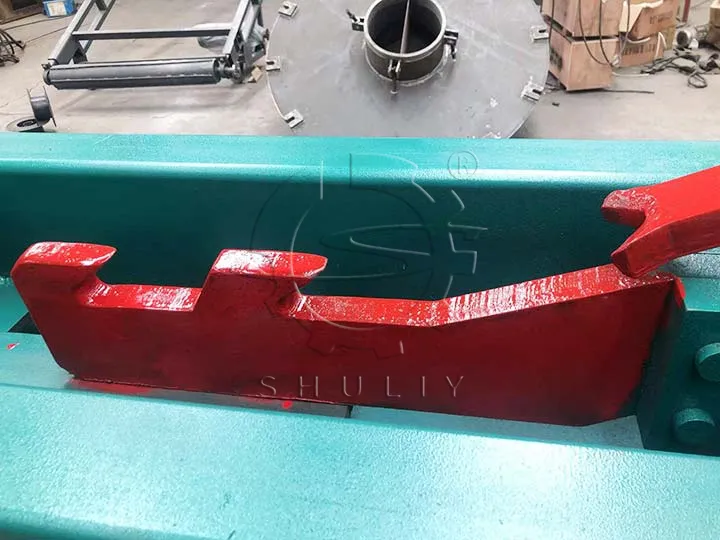

Процесс удаления корда начинается с размещения шины на порте извлечения машины для вытяжки проволоки из шин. Прочный стальной крюк, приводимый в действие гидравлической системой с приводом от двигателя, вставляется в шину, чтобы захватить проволоку корда, встроенную в боковину шины.

Под действием гидравлического давления крюк совершает возвратно-поступательное движение и эффективно и чисто вытягивает стальную проволоку. Этот процесс минимизирует потерю резины и предотвращает обрыв проволоки, гарантируя полное извлечение стали и готовность шины к дальнейшей обработке.

Рабочее видео машины для удаления стальной проволоки из отработанных шин

Два типа дебидеров для шин в продаже

Мы предлагаем два основных типа дебидеров для шин, отвечающих различным эксплуатационным потребностям:

- Однокрючковый удалитель борта: Удаляет проволоку борта с одной стороны шины за раз. Идеален для операций с умеренными требованиями к обработке.

- Двукрючковый удалитель борта: Одновременно извлекает проволоки борта с обеих сторон шины, значительно повышая эффективность обработки и пропускную способность.

Почему важна очистка шин от корда?

Удаление стальной проволоки из шин перед измельчением или дроблением критически важно по нескольким причинам:

- Защищает машины для измельчения шин и мельницы для резиновой крошки от чрезмерного износа

- Повышает эффективность обработки в последующих машинах

- Позволяет перерабатывать чистую стальную проволоку, которую можно продавать отдельно

- Обеспечивает постоянный размер частиц и качество конечной резиновой крошки

Краткое введение в параметры дебидера для шин

Мы предлагаем клиентам на выбор две модели машин для удаления стальной проволоки из отработанных шин: с одинарным и двойным крюком.

Модель дебидера с одинарным крюком оснащена двигателем мощностью 11 кВт, общие размеры составляют 4,1 × 0,7 × 1,7 метра, а вес — примерно 1400 кг. Он подходит для обработки шин диаметром от 900 до 1200 мм, с производительностью 20–30 шин в час.

Машина дебидера с двойным крюком использует двигатель мощностью 18,5 кВт, имеет размеры 4,2 × 0,9 × 1,7 метра и весит 1500 кг. Она обрабатывает шины того же размера, но обеспечивает более высокую эффективность, обрабатывая 40–50 шин в час.

Выберите подходящий дебидер для шин для вашей линии переработки

Независимо от того, управляете ли вы небольшим заводом по переработке шин или крупным предприятием по переработке шин, выбор правильного устройства для снятия бортового кольца шин является ключевым шагом на пути к эффективной и прибыльной переработке. Наша команда предлагает индивидуальные решения, основанные на типах ваших шин, производительности и потребностях в автоматизации.

Свяжитесь с нами сегодня, чтобы узнать больше о наших машинах для удаления корда из шин и получить экспертные рекомендации для вашего проекта по переработке шин.