Notre machine de broyage de ferraille est la pierre angulaire d'une opération de recyclage des métaux moderne et rentable, spécialement conçue pour réduire efficacement le volume de divers métaux ferreux. Dans notre entreprise, nous ne vendons pas seulement des machines ; nous fournissons des solutions robustes à couple élevé adaptées à vos besoins uniques. Nous mettons l'accent sur la durabilité, la performance et la personnalisation complète, vous assurant ainsi une machine qui maximise votre efficacité de recyclage et votre retour sur investissement.

Quels matériaux notre déchiqueteuse à double arbre peut-elle traiter ?

Nos machines de déchiquetage de métaux ferreux sont incroyablement polyvalentes. Bien qu'elles excellent dans le traitement des métaux, leur conception puissante leur permet de gérer une grande variété d'autres déchets.

Métaux

- Voitures de récupération, véhicules en fin de vie (ELV)

- Fûts en acier, seaux de peinture, barils d'huile

- Profilés en aluminium, portes et fenêtres

- Blocs-moteurs et pièces moulées de récupération

- Déchets de métaux légers, tôles métalliques

- Fils de cuivre, câbles en aluminium, radiateurs

- Boîtes en aluminium et ferraille compactée

Plastiques

- Bouteilles en plastique (PET), fûts en plastique, cuves IBC

- Paniers en plastique, caisses, palettes

- Sacs tissés, sacs jumbo, film agricole

Caoutchouc & Pneus

Pneus de voiture, pneus de camion (doivent être dé-wirés pour certains modèles)

Bois

Palettes en bois, bois de construction, racines d'arbres

Avantages clés de notre Déchiqueteuse à Ferraille à Double Arbre

Nous nous concentrons sur les bénéfices tangibles qui impactent directement vos opérations.

- Polyvalence du traitement des matériaux : Conçu pour gérer non seulement le métal, mais une vaste gamme de matériaux difficiles, en faisant un investissement polyvalent pour votre yard de recyclage.

- Solutions entièrement personnalisables : nous personnalisons la conception des lames, l’épaisseur, le nombre de griffes et les dimensions de la machine pour correspondre parfaitement à vos matériaux et à vos exigences de production.

- Large gamme de modèles : des broyeurs de petite taille aux systèmes à grande capacité, nous proposons une ligne complète de produits pour répondre à différentes capacités et budgets.

- Options d’alimentation flexibles (Électrique ou Diesel) : Pour les chantiers dépourvus d’une alimentation électrique triphasée stable, nous pouvons équiper votre machine déchiqueteuse de ferraille d’un puissant moteur diesel pour une mobilité et une liberté opérationnelle complètes.

- Système de Contrôle PLC Intelligent : La machine est équipée d’un système PLC qui assure une protection automatique contre les surcharges. Si la machine détecte une bourrage, les arbres s’inversent automatiquement pour dégager le matériau, puis reprennent le broyage, protégeant le moteur et la boîte de vitesses.

Comment cela fonctionne : Broyage de précision et contrôle de la taille

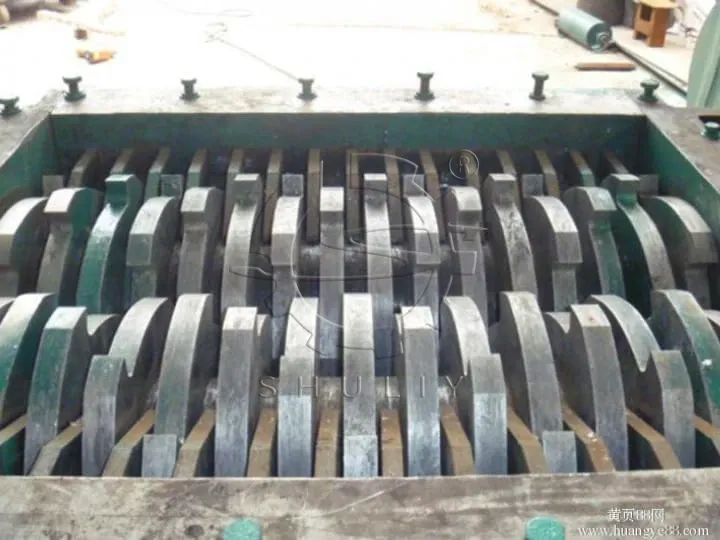

Notre déchiqueteuse à double arbre fonctionne sur le principe de cisaillement et de déchirure. Le matériau est introduit par le godet et saisi par les arbres opposés munis de lames tranchantes et interverrouillées. Le couple élevé et la vitesse lente des arbres permettent à la machine de déchirer et de découper fortement le matériau en morceaux plus petits.

Pour les clients qui nécessitent une taille de sortie uniforme, nous pouvons installer un écran de taille personnalisée ( tamis circulaire). Le matériau broyé à la taille souhaitée passe à travers l’écran, tandis que les morceaux plus gros sont ramenés vers le haut par les lames pour un broyage supplémentaire jusqu’à ce qu’ils soient assez petits pour passer. La taille finale du matériau est réglable et peut être contrôlée précisément en changeant la configuration des lames et la taille de la maille de l’écran.

Regardez notre machine déchiqueteuse de ferraille en action

Voyez par vous-même comment notre machine déchiqueteuse de ferraille traite sans effort les ferrailles lourdes.

Foire Aux Questions (FAQ) de la Déchiqueteuse à Double Arbre

Q1 : Quelle est la taille de sortie finale du matériau broyé ?

A : La taille de sortie est entièrement personnalisable. Nous configurerons la machine selon vos exigences spécifiques.

Q2 : Pouvez-vous proposer une solution pour mon type spécifique de ferraille ?

A : Absolument. Nous vous encourageons à nous envoyer un échantillon de votre matériau. Nous proposons des tests de matériau gratuits pour déterminer la meilleure configuration de machine pour vous.

Q3 : Qu’en est-il du service après-vente et des pièces détachées ?

A : Nous proposons un support après-vente complet, y compris des conseils d’installation et une formation opérationnelle. Des pièces détachées clés comme les lames sont disponibles en stock pour minimiser vos temps d’arrêt.

Application dans la ligne de recyclage de l'aluminium à rupture thermique

Cette machine de déchiquetage de métaux ferraille peut également servir d'équipement de concassage principal dans les lignes de recyclage de profils en aluminium à rupture thermique. Elle réduit les profils en aluminium à rupture thermique par déchirure et cisaillement, aidant à libérer l'aluminium des bandes d'isolation en plastique et à préparer le matériau pour le concassage secondaire et la séparation par courant de Foucault.

Différents modèles sont disponibles pour correspondre à diverses capacités et conditions de matériaux.

Contactez-nous pour sélectionner un modèle de déchiqueteuse adapté à votre projet de recyclage de l'aluminium à rupture thermique.

Élargissez vos capacités de traitement des métaux

Bien qu’une déchiqueteuse de ferraille soit un élément central pour traiter une large gamme de matériaux, nous proposons également d’autres équipements spécialisés pour gérer différents aspects du recyclage des métaux. Combiner ces machines peut vous aider à créer une opération plus complète et efficace.

Engineur de Métal : Notrebalayeuse de ferrailleest parfaite pour comprimer les matériaux libres, y compris la ferraille hachée ou les métaux légers, en ballots denses et faciles à manipuler. Ce processus réduit considérablement les coûts de stockage et de transport, rendant votre produit final plus attractif pour les aciéreries et les fonderies.

Cisaille à portique : Pour les ferrailles lourdes ou volumineuses qui dépassent la capacité d’alimentation de la déchiqueteuse, notre robustecisaille à portiqueest la solution idéale. Elle coupe efficacement les grands éléments comme les poutres en I, les tuyaux et les plaques lourdes en tailles gérables, les préparant pour le déchiquetage ou pour une vente directe.

Obtenez dès aujourd’hui votre devis personnalisé pour une déchiqueteuse de ferraille !

Prêt à améliorer vos capacités de recyclage et à augmenter vos profits ? Notre équipe d’experts est là pour vous aider à choisir la machine de broyage industrielle idéale.

Contactez-nous aujourd’hui pour un devis sans engagement et une consultation gratuite. Remplissez simplement le formulaire avec vos exigences, ou pour une réponse plus rapide, ajoutez-nous sur WhatsApp. Nous vous fournirons une proposition technique détaillée, les tarifs et des conseils d’experts pour vous aider à prendre la meilleure décision pour votre entreprise.