Un concasseur de métaux est un équipement central dans l'industrie du recyclage des métaux, conçu pour traiter efficacement divers types de ferraille métallique et le transformer en matériau à haute densité facile à gérer et à transporter. Cet équipement, également appelé machine de concassage de ferraille ou concasseur d'aluminium, peut fonctionner efficacement en tant qu'unité autonome ou être intégré à d'autres équipements tels qu'un hachoir à métaux et un séparateur à courant de Foucault pour former une ligne de recyclage de l'aluminium à rupture thermique ou une ligne de production de concassage et de tri de métaux, ce qui en fait une solution idéale pour les demandes modernes de recyclage des métaux.

Large gamme de capacités de traitement des matériaux

Notre puissant concasseur de métaux peut traiter plus de 200 types différents de matériaux métalliques, ce qui en fait un atout précieux pour toute entreprise de traitement des métaux. Sa conception robuste peut facilement broyer :

- Véhicules de ferraille : carrosseries de voitures broyées ou démantelées, motos de ferraille, vélos électriques et cadres de bicyclettes.

- Matériaux légers et fins : matériaux métalliques légers coupés ou ballés avec une densité ne dépassant pas 1 t/m³.

- Appareils ménagers : grands appareils tels que vieilles machines à laver, réfrigérateurs, climatiseurs et tuiles en acier coloré.

- Différents contenants métalliques et ferraille : canettes de boissons jetées, seaux de peinture, aluminium de rebut, tôles de fer de rebut, acier de rebut, et autres vieux métaux.

- Débris de construction : portes et fenêtres en aluminium à rupture thermique, radiateurs, et autres produits en ferraille.

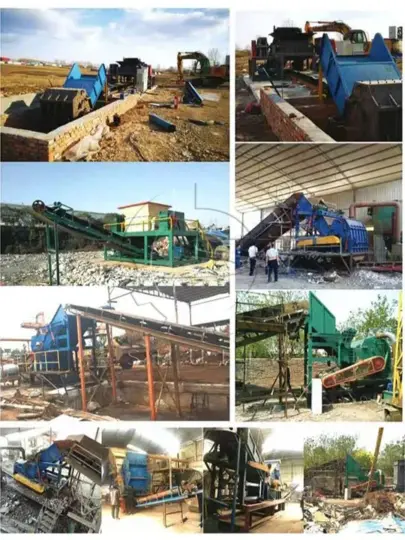

Principaux domaines d'application du concasseur de ferraille métallique

Cet équipement est un investissement idéal pour les entreprises dédiées à la régénération des ressources et au traitement efficace, servant principalement :

- Centres de recyclage et de traitement de ferraille

- Centres de démantèlement de véhicules en fin de vie (VFV)

- Filiales des aciéries

- Entreprises professionnelles de recyclage de ferraille

Conception supérieure pour des performances exceptionnelles

Notre concasseur d'aluminium est conçu en tenant compte de la performance, de la durabilité et de la sécurité, garantissant une sortie stable, durable et efficace à long terme pour nos clients.

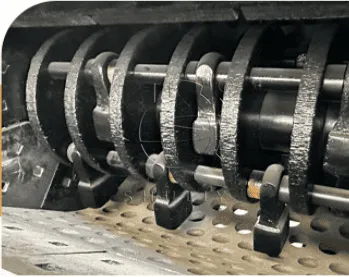

Système de concassage puissant: Il utilise un principe de concassage à marteau. Les plaques de revêtement et les têtes de marteau sont moulées en acier au manganèse résistant à l'usure de haute résistance, prolongeant considérablement leur durée de vie. Les marteaux sont montés de manière flexible, leur permettant de balancer en cas de rencontre avec des objets indestructibles. Cela permet à l'objet dur d'être évacué par une sortie dédiée, évitant efficacement les dommages à l'équipement et assurant une production continue.

Corps robuste et durable: Le corps de la machine est construit à partir de plaques d'acier épaisses et renforcé avec des supports diagonaux pour gérer facilement les tâches de concassage lourd. Des processus de soudure et de polissage exquis assurent la durabilité, la sécurité et la fiabilité à long terme de l'équipement.

Composants principaux de haute qualité :

- Rotor robuste et roulements: Le rotor lourd, fabriqué selon des processus rigoureux, garantit une opération de haute qualité. Les logements de roulements sont en acier moulé, renforçant considérablement la résistance radiale et la stabilité de l'équipement.

- Moteur efficace et économe en énergie: Il utilise un moteur à noyau en cuivre entièrement en cuivre pour réduire la consommation d'énergie tout en fournissant une puissance forte et une durée de vie plus longue.

Caractéristiques de sécurité complètes: L'équipement est équipé d'un système de protection contre la surcharge du moteur et d'un verrouillage de l'alimentation pour assurer la sécurité opérationnelle. Les plaques de corps épaissies et un design d'entrée d'alimentation scellée empêchent efficacement les éclaboussures de matériau lors du concassage.

Vidéo de fonctionnement du concasseur d'aluminium

Services de sortie de haute qualité et de personnalisation

Le matériau broyé est uniforme en forme, ce qui facilite son transport, son stockage et sa refonte, augmentant ainsi sa valeur économique.

- Forme du matériau de sortie: Les matériaux fins comme les canettes de boisson sont broyés en petites boules uniformes, tandis que les matériaux plus épais sont cassés en flocons ou petits morceaux.

- Taille de particule de sortie: La taille de particule de sortie standard varie de 3 à 10 mm. Nous proposons également des services de personnalisation en fonction des exigences spécifiques du client pour la taille de sortie.

- Production automatisée: Les systèmes de convoyage peuvent être configurés à l'entrée et à la sortie pour réaliser un alimentation et un déchargement automatisés en continu, améliorant ainsi l'efficacité globale de la production.

Modèles de produits et paramètres techniques

Nous proposons une variété de modèles de concasseurs métalliques pour répondre à des besoins allant de petites opérations à une grande production industrielle.

| Modèle | Puissance (kW) | Vitesse du rotor (r/min) | Capacité (kg/h) | Dimensions (mm) |

| SL-600 | 18.5-22 | 860 | 600-800 | 2000x1200x1900 |

| SL-800 | 30-37 | 860 | 800-1000 | 2200x1500x2200 |

| SL-1000 | 55-75 | 860 | 2500-3500 | 2800x1900x3100 |

| SL-1300 | 90-110 | 750 | 3500-5000 | 3500x2100x3800 |

| SL-1600 | 110×2 | 750 | 4000-8000 | 4400x2500x4200 |

| SL-1800 | 160×2 | 650 | 8000-12000 | 4700x2900x4500 |

| SL-2000 | 220×2 | 650 | 10000-18000 | 5000x3200x4600 |

Contactez-nous pour plus de détails et de prix sur les concasseurs de métaux

Le concasseur métallique de Henan Shuliy Machinery Co., Ltd est un équipement puissant, fiable et polyvalent. Avec sa construction durable, ses fonctionnalités de sécurité avancées et sa capacité à produire des matériaux de haute qualité et uniformes, il constitue le choix idéal pour les entreprises souhaitant optimiser leurs processus de recyclage des métaux, réduire les coûts de transport et améliorer l'efficacité de la fusion.

Êtes-vous prêt à améliorer vos opérations de recyclage des métaux ? Notre équipe d'experts est prête à vous aider à choisir le concasseur métallique idéal pour vos matériaux et capacités spécifiques. Contactez-nous dès aujourd'hui pour une consultation personnalisée et un devis sans obligation. Laissez-nous fournir la solution parfaite pour augmenter votre efficacité et votre rentabilité.