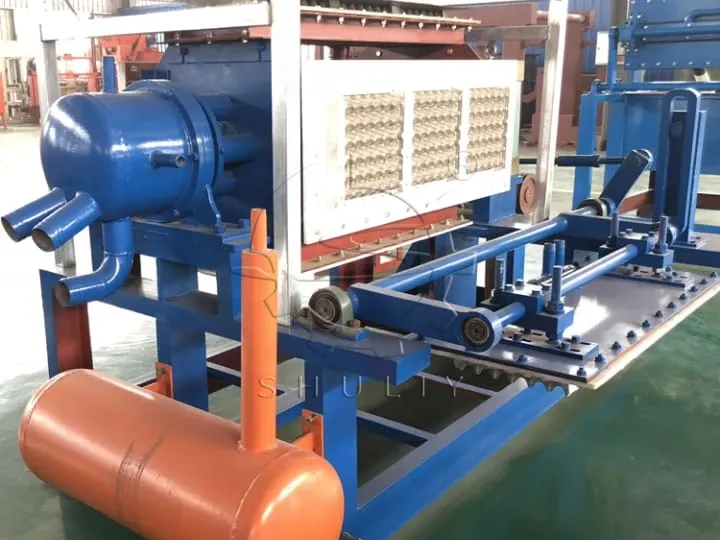

La machine à fabriquer des plateaux à œufs, également appelée machine à fabriquer des plateaux en papier, est un type d'équipement qui transforme la pulpe de papier recyclé en différents types de plateaux en papier. Bien que son utilisation la plus courante soit la production de plateaux à œufs, la machine peut également fabriquer des plateaux à fruits, des porte-gobelets et des plateaux d'emballage pour l'électronique en changeant simplement les moules. Elle joue un rôle important dans le recyclage des ressources en papier usagé.

Nous proposons des machines à barquettes à œufs avec des capacités allant de 1 000 à 8 000 pièces par heure, adaptées aux petites fermes comme aux grandes usines. Nos machines sont durables, faciles à utiliser et prennent en charge des moules personnalisés pour la production de diverses barquettes en pulpe. Nous fournissons des solutions complètes, y compris le défibrage, le formage, le séchage et l'emballage, ainsi que le support d'installation, la formation et le service après-vente.

Vidéo de fonctionnement de la machine à plateaux en papier

Fonction et applications de la machine à fabriquer des plateaux à œufs

La fonction principale de la machine à fabriquer des plateaux en papier est de transformer des matériaux en papier usagé en plateaux biodégradables utilisés pour l'emballage, la protection et le transport des œufs, des fruits, des boissons et de petits articles électroniques. Les scénarios d'application courants incluent :

- Emballage d'œufs dans les fermes avicoles

- Production de plateaux à œufs pour les usines de transformation des œufs et les supermarchés

- Production de plateaux à fruits pour le transport agricole

- Production de porte-gobelets pour cafés et services de plats à emporter

- Plateaux en pulpe protecteurs pour l'électronique et les biens fragiles

Matières premières et produits finis

Matières premières

La machine à fabriquer des plateaux à œufs utilise du papier usagé courant pour créer de la pulpe, y compris :

- Anciens journaux (ONP)

- Cartons usagés (OCC)

- Papier de livre usagé, papier d'impression

- Chutes et restes de papier d'usine

Types de produits finis

Avec des changements de moules, la machine de moulage en pulpe de papier peut produire :

- Plateaux à œufs de 30 cellules

- Plateaux à œufs de 12 cellules et de 6 cellules

- Carton à œufs (avec couvercle)

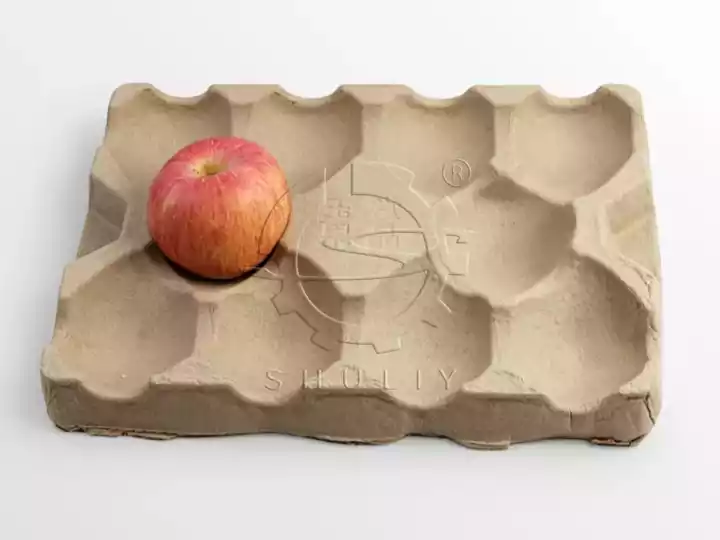

- Plateaux à fruits (par exemple, plateaux à pommes)

- Porte-gobelets (2 gobelets / 4 gobelets)

- Plateaux à chaussures, plateaux à bouteilles, plateaux à ampoules, etc.

Avantages de notre machine à plateaux d'œufs

En tant que fabricant professionnel de machines à fabriquer des plateaux à œufs, nos machines offrent les avantages suivants :

- Gamme de modèles complète: Des machines unidirectionnelles aux machines multi-faces pour diverses capacités de production.

- Options de moules personnalisés: Personnalisation flexible des moules pour différents types de plateaux.

- Bonne qualité de produit: Les plateaux à œufs ont une forme et une épaisseur uniformes, une forte capacité de charge, et protègent efficacement les œufs tout en ajoutant de la valeur au produit.

- Solution tout-en-un: Nous offrons un service complet ligne de production de plateaux à œufs, y compris les systèmes de pulpage, de formation, de séchage, d'empilage et d'emballage.

- Support technique complet: Conseils d'installation, formation à l'utilisation et services après-vente fournis.

Modèles de machines et capacité de production

Les modèles de machines à fabriquer des plateaux à œufs sont généralement représentés sous la forme "moules × côtés", par exemple 4×1 pour une machine à un seul côté avec 4 moules, et 4×4 pour une machine à quatre côtés avec 16 moules. Différents modèles déterminent le nombre de moules impliqués dans chaque cycle de formation, ce qui affecte directement la production horaire.

Machines à une face (par exemple, 3×1, 4×1)

- Structure simple avec des moules d'un côté.

- Idéal pour la production à petite échelle ou les startups.

- Production inférieure, typiquement 1000–2000 plateaux/heure.

- Petite empreinte, faible consommation d'énergie, et facile à utiliser.

- Idéal pour une utilisation avec séchage au soleil ou systèmes de séchage à petite échelle.

| Modèle | Nombre de moisissures | Sortie approximative (plateaux/heure) | Puissance/heure |

| 3×1 | 3 moules | 1000-1500pcs/h | 38kW |

| 4×1 | 4 moules | 1500-2000pcs/h | 38kW |

Machines multi-faces (par exemple, 3×4, 4×4, 4×8, 5×8, 6×8, 5×12)

- Structure rotative, plusieurs ensembles de moules fonctionnent en séquence.

- Convient aux usines de taille moyenne à grande avec une demande constante.

- Production plus élevée, allant de 2000 à plus de 8000 plateaux/heure.

- Peut être équipé de systèmes de séchage, d'empilage et d'emballage automatiques.

- Conçu pour la production de masse avec une haute efficacité.

| Modèle | Nombre de moisissures | Sortie approximative (plateaux/heure) | Puissance/heure |

| 3×4 | 12 moules | 2000-2500pcs/h | 55kW |

| 4×4 | 16 moules | 2500-3000pcs/h | 60kW |

| 4×8 | 32 moules | 4000-5000pcs/h | 95kW |

| 5×8 | 40 moules | 5000-6000pcs/h | 95kW |

| 6×8 | 48 moules | 6000-7000 pcs/h | 120 kW |

| 5×12 | 60 moules | 7000-8000pcs/h | 120 kW |

Processus de travail de la machine à fabriquer des plateaux d'œufs

Le processus de production comprend quatre étapes principales :

- pulpage: Le papier usagé est mélangé avec de l'eau et transformé en pulpe uniforme.

- Formation: La pulpe est formée sous vide sur des moules pour créer des plateaux humides.

- Séchage: Les plateaux humides sont séchés à l'aide de lignes de séchage en métal, de fours à briques ou par séchage naturel au soleil.

- FinitionLes plateaux séchés sont formés, empilés et emballés pour la vente.

Production de plateaux en papier polyvalents avec changement de moule

En plus des plateaux à œufs standard, nous fournissons des machines à fabriquer des plateaux en papier multi-usages capables de produire :

- Machine à fabriquer des plateaux de fruitsAdapté à l'emballage et au transport de fruits tels que les pommes, les poires et les pêches, protégeant contre la pression et les chocs.

- Machine à plateaux à caféUtilisé pour produire des porte-gobelets en pulpe moulée de 2 ou 4 tasses, largement utilisés dans les magasins de plats à emporter et de boissons.

- Machine industrielle à plateaux rembourrésConçu pour fabriquer des plateaux de protection pour les produits électroniques, les ampoules, la verrerie et d'autres articles fragiles, offrant une excellente absorption des chocs.

- Machine à fabriquer des plateaux à chaussures : Idéale pour l'emballage de chaussures et de baskets, aidant à maintenir leur forme et à les protéger pendant le transport.

Machine à fabriquer des plateaux à œufs à vendre

La machine à fabriquer des plateaux à œufs est une solution durable, efficace et polyvalente pour produire des produits d'emballage en pulpe. Largement utilisée dans l'agriculture, le commerce de détail, la restauration et l'industrie, elle offre à la fois des avantages environnementaux et économiques. En tant que fournisseur expérimenté de machines à plateaux à œufs, nous offrons un soutien complet, de la consultation et de la conception à l'installation et au service après-vente. N'hésitez pas à nous contacter pour un plan de production personnalisé et un devis.